- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Zhangsheng

-

Voltage:

-

380V

-

Motor Power (Kw):

-

110

-

Power (kW):

-

110

-

Weight (KG):

-

6500 KG

-

Name:

-

straw pellet making machine

-

Capacity:

-

1-10T/H

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Function:

-

Make Wod Pellet

-

Pellet size:

-

6/8/10/12mm

-

Color:

-

Customer`s Request

-

Brand:

-

Zhangsheng

-

Turn-key line:

-

Provide Complete Pellet Production Line

-

Main product:

-

Biomass Pellet Machine

-

Keywords:

-

straw pellet making machine

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

1000 - 10000 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhangsheng

-

Voltage:

-

380V

-

Motor Power (Kw):

-

110

-

Power (kW):

-

110

-

Weight (KG):

-

6500 KG

-

Name:

-

straw pellet making machine

-

Capacity:

-

1-10T/H

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Function:

-

Make Wod Pellet

-

Pellet size:

-

6/8/10/12mm

-

Color:

-

Customer`s Request

-

Brand:

-

Zhangsheng

-

Turn-key line:

-

Provide Complete Pellet Production Line

-

Main product:

-

Biomass Pellet Machine

-

Keywords:

-

straw pellet making machine

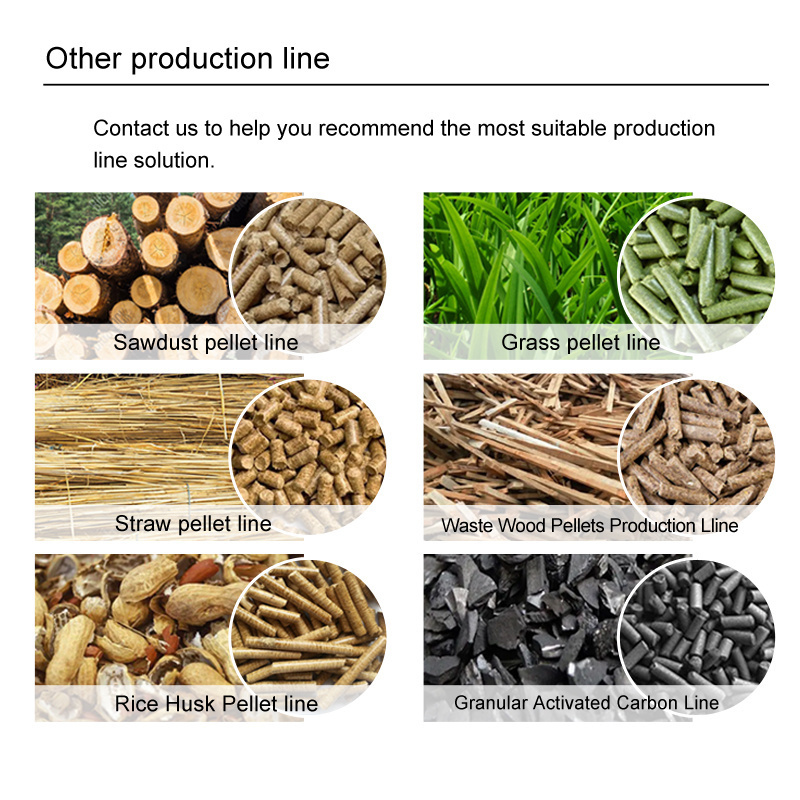

Straw is an agricultural by-product consisting of dry straw from which grains and chaff have been removed. Straw pellets have the advantages of renewable, emission reduction, low pollution and economy. Unlike fossil fuels, straw resources are endless as plants grow.

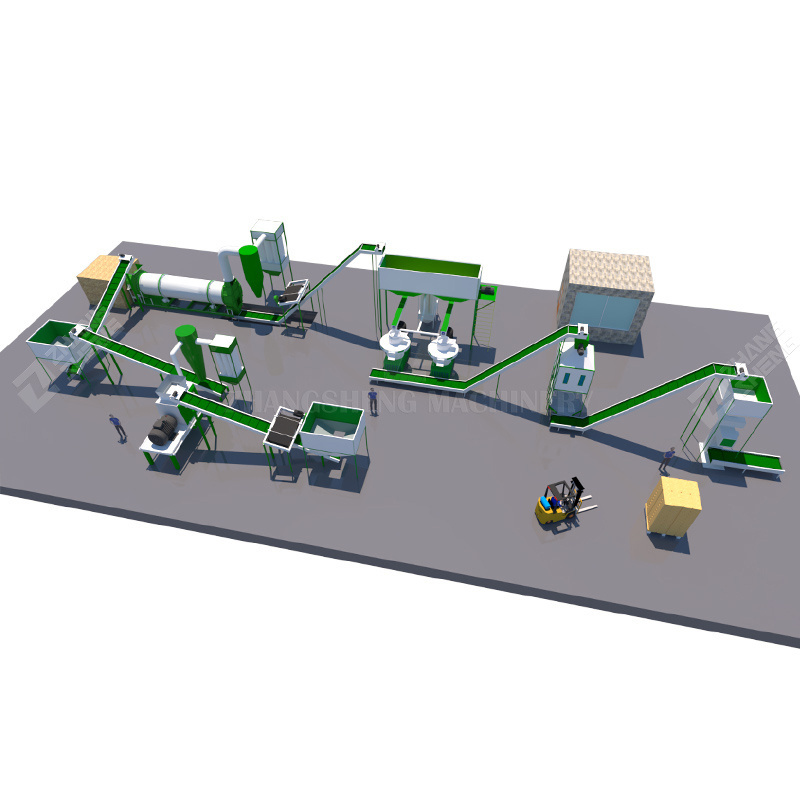

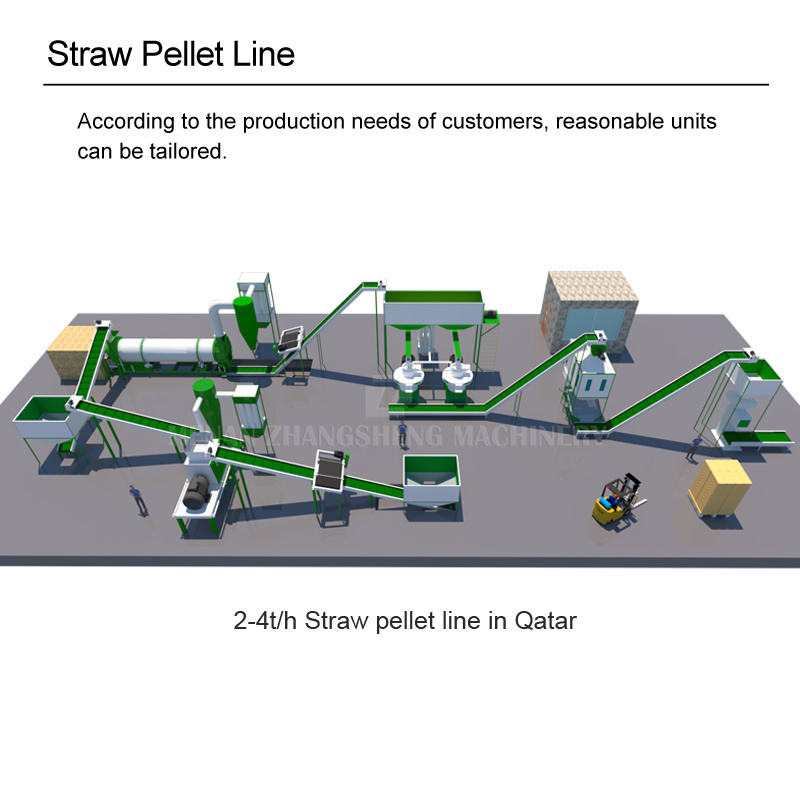

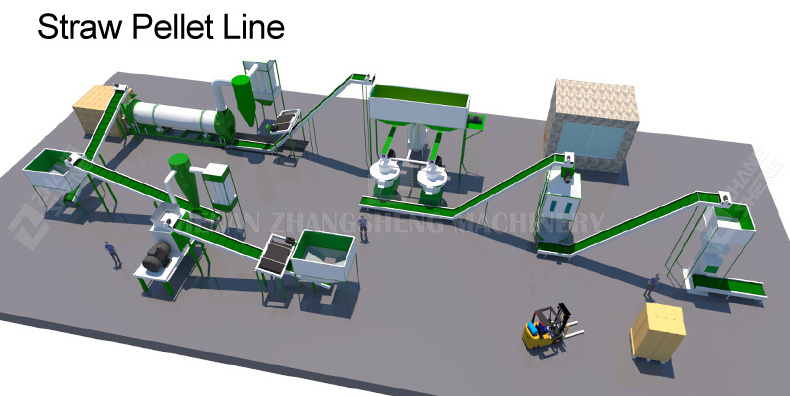

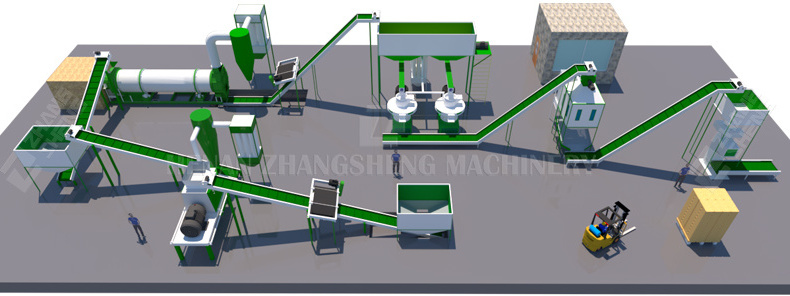

ZhangSheng Straw pellet production line integrates all processes from raw materials to pellets, including crushing, drying, pellet making, cooling and packing, with an output of 1 to 10 tons per hour.

A lucrative project - biomass pellets production

Straw pellets can not only alleviate energy shortages, but also one of the most effective ways to achieve renewable energy and carbon reduction goals.

The value of straw pellets has not been taken seriously. There is still a large amount of crop straw that is neglected and directly burned. In a large agricultural country with rich straw resources, starting a straw pellet production line is indeed a very promising project. Under the high energy cost, straw pellet is a very good thermal energy source, straw pellet line is a promising and lucrative project.

Why Choose US

Process Flow

Wood Drum Chipper

(

Straw

pellet line doesn't need this process)

Primary crushing stage process tree trunks and logs with a diameter of less than 50cm, into small wood chips within 20mm.

Hammer Mill

Hammer mill process small wood chips with a diameter of less than 20mm into sawdust with a diameter of less than 8mm.

Rotary dryer/Air Flow Dryer

(optional)

The optimum moisture content for granulation is 12-18%. The dryer reduces the wood sawdust moisture from 20%-60% to 12-18%.

Pellet Mill

The pellet mill makes dry sawdust into pellets, and the output of a single machine can reach 3t/h.

Cooler

The cooling system cools the pellets from 70-90 ℃ to room temperature, and the hardness of the pellets will become stronger.

Packing Machine

Pack the qualified pellets from 10kg, 20kg or 1 ton into a plastic bag, and then sew with a thermoplastic sealing machine to make the pellets dry and waterproof.

Note: This is a conventional simple biomass pellet production line, we can customize different pellet production plans for you according to different sites, raw materials, output and budget. As a leading pellet machine manufacturer in China, ZhangSheng has rich experience in pellet machine manufacturing, and can build a unique pellet mill for you according to the actual situation.

Case show

Experience of manufacturing and installing project globally, which help them get huge economic benefits.

Hot Searches