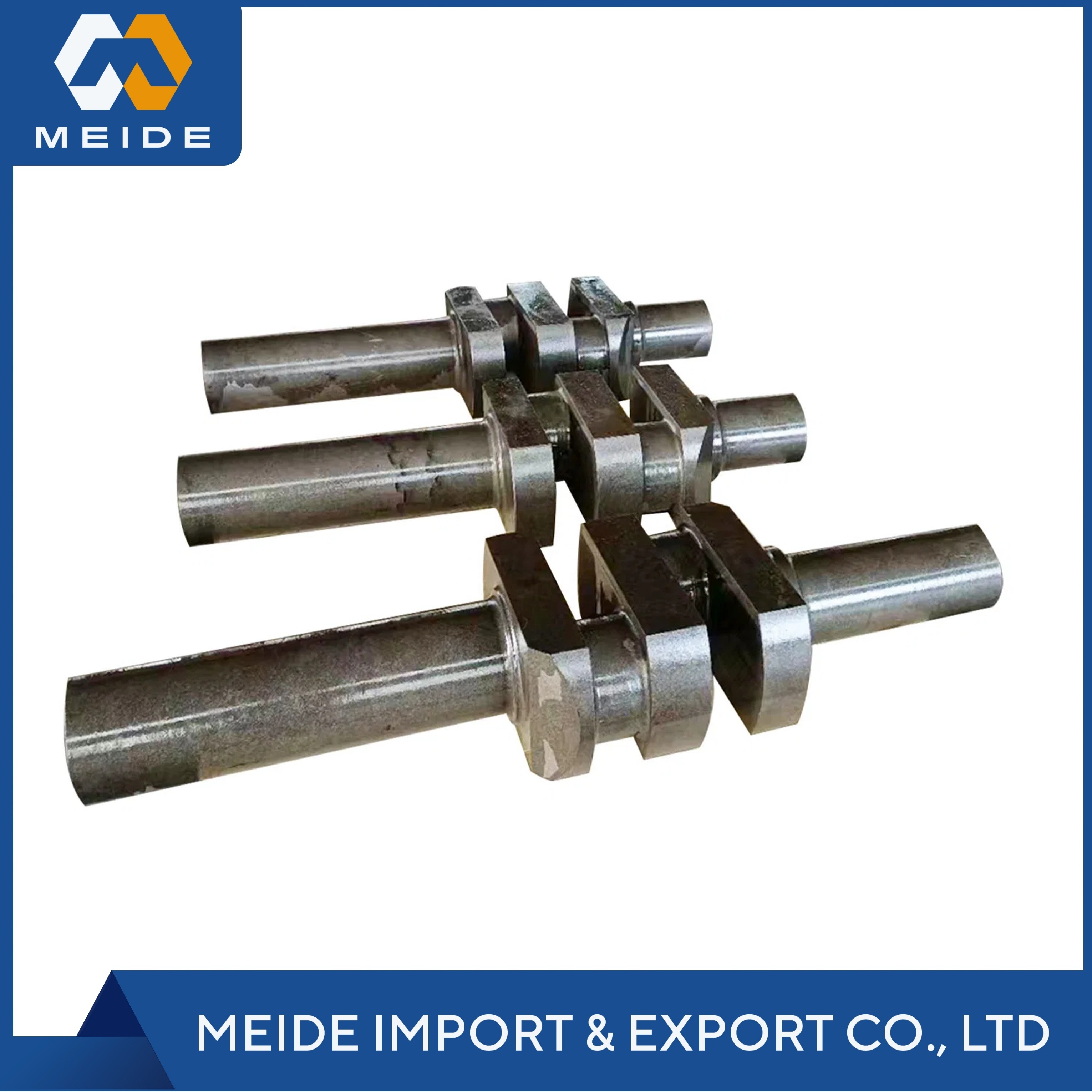

- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Alloy steel carbon steel

-

Product name:

-

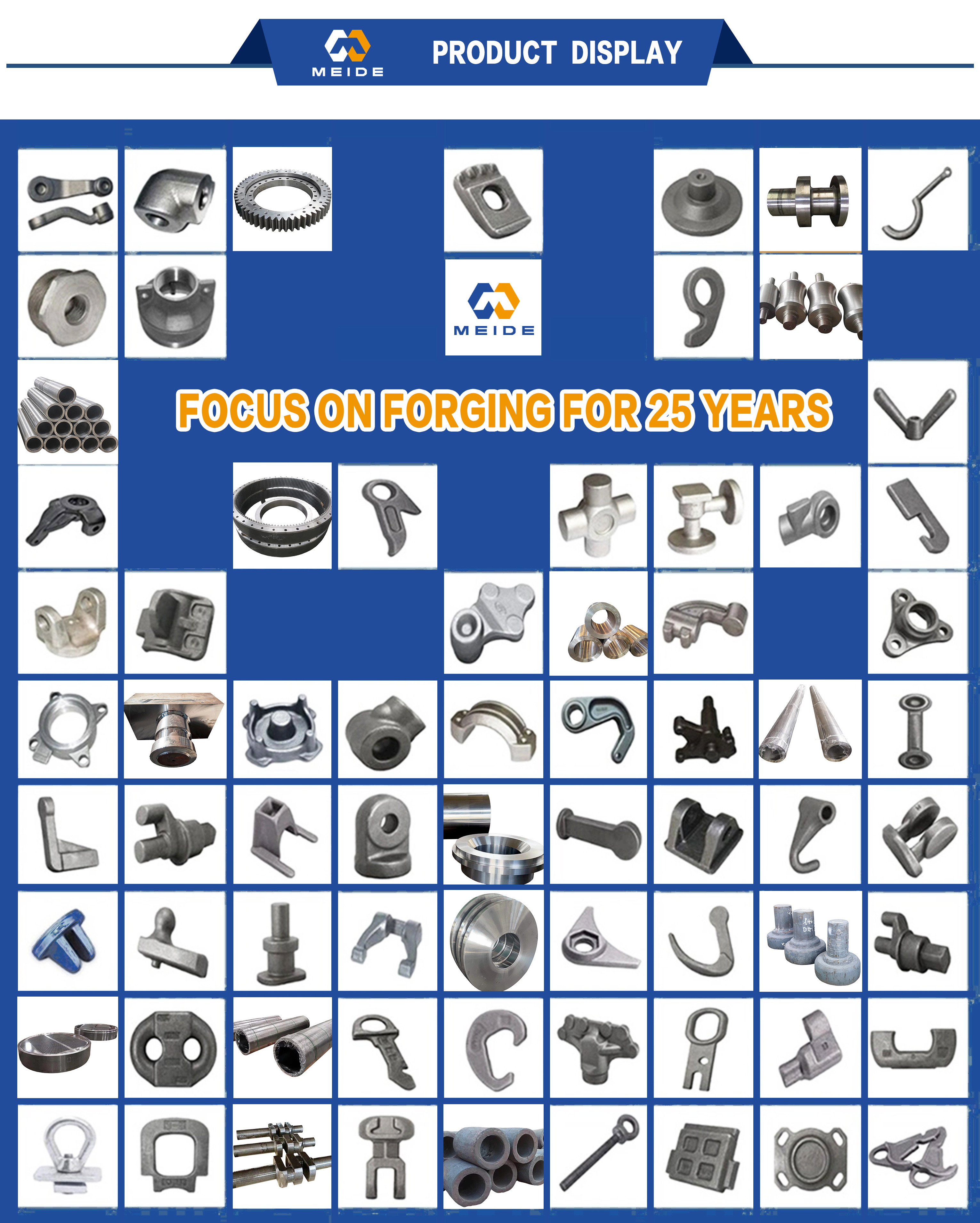

Forging Metal Parts

-

MOQ:

-

10 Piece

-

Keyword:

-

OEM Hot Forging Parts

-

Application:

-

Industry

-

Surface treatment:

-

Polishing

-

Service:

-

OEM\ODM

-

Process:

-

Forging+Machining(if Need)+surface Treatment

-

Certificate:

-

ISO9001

-

Size:

-

Customer's Requst

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Meide

-

Model Number:

-

customization

-

Material:

-

Alloy steel carbon steel

-

Product name:

-

Forging Metal Parts

-

MOQ:

-

10 Piece

-

Keyword:

-

OEM Hot Forging Parts

-

Application:

-

Industry

-

Surface treatment:

-

Polishing

-

Service:

-

OEM\ODM

-

Process:

-

Forging+Machining(if Need)+surface Treatment

-

Certificate:

-

ISO9001

-

Size:

-

Customer's Requst

Product Description

|

Available Material:

|

Carbon steel alloy steel, etc

|

|

Heat Treatment:

|

Annealing,Quenching,Nitriding,Hardening,Tempering,Normalizing,etc.

|

|

Tolerance:

|

As per drawing.(+/-0.05mm,+/-0.01mm)

|

|

Surface Treatment:

|

Zinc-Plated,Nickel-Plated,Chrome-Plated,Anodize,Phosphating,Chemical Blackening,Salt Bath Nitriding,etc.

|

|

Lead Time:

|

20-45Days Depends On Quantities and complexity

|

|

Application:

|

Forklift,Crane,Train,Truck,Lawnmower,Rail Road Euipment,medical device, industrial machine, automobile, electric

appliance,Automation machine,other industries,etc, |

|

Payment Term:

|

L/C at sightT/T 30% deposit and balanced 70% to pay before shipment.

|

|

Port Of Loading:

|

Shanghai or Ningbo,etc.

|

|

Production Equipment:

|

CNC Machining center,CNC Lathe,Grinding Machine,Milling Machine,Sawing Machine,Welding Machine,Hydraulic Press Machine,Drilling

and Tapping Machine,Gear Shaping Machine,etc. |

|

Inspection Equipment:

|

Electronic Penumatic Measuring Instrument,Three Coodinate Detection Equipment,Rockwell Hardness Tester,Digital Ultrasonic Flaw

Detector,Surface Roughness Measuring Instrument,Leeb Hardness Tester,Cladding Measuring Instrument,Salt Spraying Tester,Gear Measurement Center,etc. |

|

QC:

|

1.Incoming material will be checked before production.2.Strict processing quality control.

3.100% inspection before shipment. 4.We are responsible for product quality to the end user. |

|

Package:

|

Method 1:Carton box or corrugated carton

Method 2:Wooden case or wooden crate Method 3: Iron basket or plastic basket Method 4: Pallet |

|

After-sales Service:

|

We will follow up goods for customers and help to solve problems after sales.

|

Technical Support

Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D softwares. We are able to design, develop,produce and deliver your PO according to your drawings, samples or just an idea. Dural control of standard products and OEM products.

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Product material

|

Carbon Steel

|

A350LF2、 A105、Q235、Q355D、A694F52、A516-GR65、EN10222、P280GH、P245GH、P250GH、JIS S25C、SS400、S20C、16Mn、C22.8、Q345B/C/D、1055、1045、C50、C45、10#、20#、35#、45#、40#、50#、60#

|

|

Alloy Steel

|

42CrMo、A182F1、F5、F9、F11、F91、F92、F22、12Cr2Mo1、10Cr9Mo1VNbN(F91)、10Cr9MoW2VNbBN(F92)、JB4726-2000、15CrMo、JB4726-2000、12CrMoV、35CrMo、4140、4340、4330、4130、4150、9CR2MO、17NiCrMo6-4、18CrNiMo7-6、20MnMo、25CRMO、20CRMO、20CRMOTI、30CrNiMo8、34CRNIMO、34CrNiMo6、36CrNiMo4、34CrNi3Mo、34CrMo1、40CRNIMO、40CrNiMoA、50CrMo4、Q345D、300M、17-4PH、PH13-8Mo、15-5PH、AerMet100

|

Company advantage

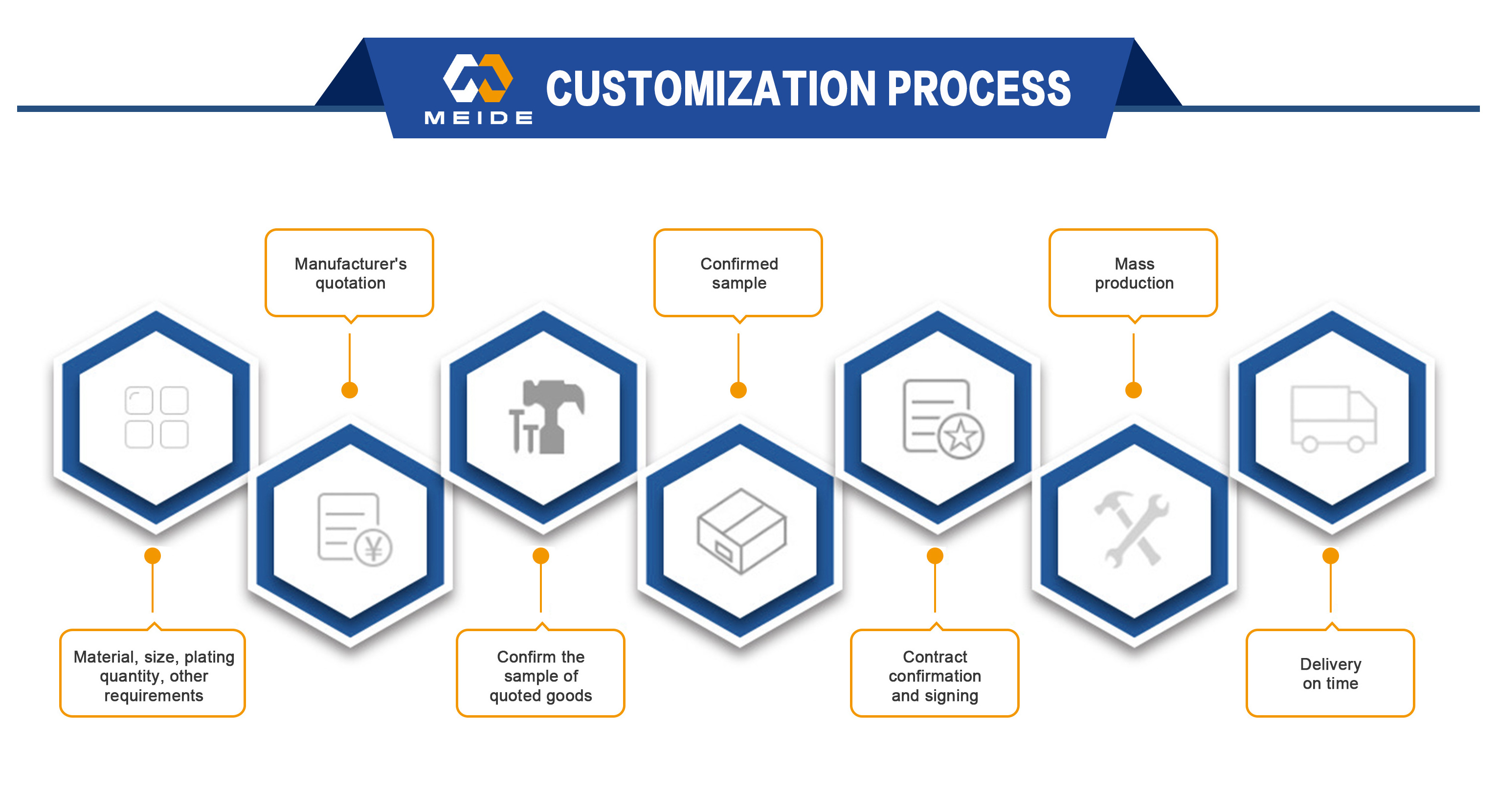

MEIDE designs, develops, produces and delivers based on your drawings, samples or just an idea!

* Provide technical process analysis, development and manufacturing integration of resources according to customer requirements, to provide different processes of OEM castings and forgings and CNC machining parts.

* We supply both machined and non-machined castings and forgings to various industries, starting with OEM suppliers.

* We are both a manufacturer and a trading company, breaking the limits of a single factory

* We have 100 strategic partners for production of different technologies

* Professional team including translators, engineers, inspectors and customer service * has developed more than 10,000 products to date

* The OEM division is the most promising member of MEIDE and will receive the strongest support from the whole group * Any OEM inquiry will be set up as a project and will be considered a focus within the Group

* 20 years of independent development and design capabilities

* 20 senior engineers

*Auto CAD/Pro Engineer /Solid Works

* Our forging processes are open die forging, precision forging, die forging

* Dual control of standard and OEM products

* Our factory has a variety of equipment, such as lathes, CNC, drilling machine, milling machine, boring machine, planer.

* Delivery time and packaging can be completely controlled according to customer requirements.

Manufacturing capacity covers the entire production process of forging parts, from mold design and manufacturing, forging, secondary processing, heat treatment, surface treatment to finishing, to provide customers with ready-to-use products and services.

|

|

1) 0-100kg: express & air freight priority

|

|

|

2) >100kg: sea freight priority

|

|

|

3) As per customized specifications

|

|

|

All parts are custom made according to customer's drawings or samples, no stock.

|

FAQ

Q1: Are you a trading company or a manufacturer?

A: We are an industrial and trading company with our own iron foundry and many outsourcing partners.

Q2: What is your lead time?

A: Approximately 15-35 days from the date of order.

Q3: Do you provide samples? Is it free or extra?

A: We can provide samples. If it's not too much, it's free. However, if we need to make the mold first, we need to charge 50% of the mold cost.

Q4: What are your payment terms?

1) Mold fee: 50% in advance, 50% after sample approval

2) Goods: 30% down payment, 70% should be received before delivery.

A: We are an industrial and trading company with our own iron foundry and many outsourcing partners.

Q2: What is your lead time?

A: Approximately 15-35 days from the date of order.

Q3: Do you provide samples? Is it free or extra?

A: We can provide samples. If it's not too much, it's free. However, if we need to make the mold first, we need to charge 50% of the mold cost.

Q4: What are your payment terms?

1) Mold fee: 50% in advance, 50% after sample approval

2) Goods: 30% down payment, 70% should be received before delivery.

Hot Searches