- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

50years

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ERA

-

Model Number:

-

PRE06

-

Keyword:

-

Male Thread Elbow Wall Plate

-

Size:

-

20x1/2''-25x3/4''

-

Color:

-

Green

-

Standard:

-

DIN8077/8088

-

Ball Material:

-

PPR

-

Modle:

-

PRE06

-

Material:

-

PPR

-

Origin:

-

ZheJiang

Quick Details

-

Technics:

-

Forged

-

Shape:

-

Equal

-

Head Code:

-

Round

-

Warranty:

-

50years

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ERA

-

Model Number:

-

PRE06

-

Keyword:

-

Male Thread Elbow Wall Plate

-

Size:

-

20x1/2''-25x3/4''

-

Color:

-

Green

-

Standard:

-

DIN8077/8088

-

Ball Material:

-

PPR

-

Modle:

-

PRE06

-

Material:

-

PPR

-

Origin:

-

ZheJiang

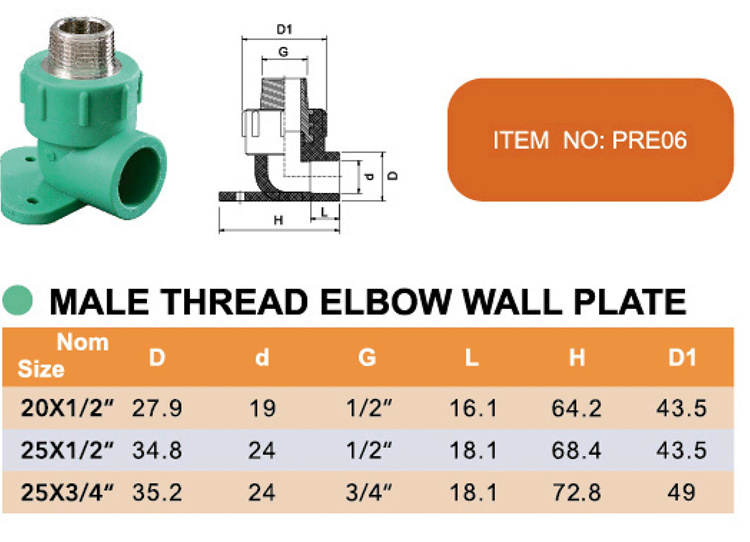

Products Description

|

Model Number

|

PRE06

|

Material

|

PPR

|

|

Description

|

MALE THREAD ELBOW WALL PLATE

|

Standard

|

DIN8077/8088

|

|

Temperature

|

Max 95ºC / 203°F

|

Working Pressure

|

PN16 16 Bar,1.6Mpa

|

|

Connection

|

Socket

|

Color

|

GREEN

|

Product Advantages

|

Adavantages

|

Benefits

|

|

Durability

|

Authoritative quality assurance

|

|

Flexibility

|

Long service life

|

|

Thermal Resistance

|

Leak-Proof

|

|

Noise Reduction

|

Longevity

|

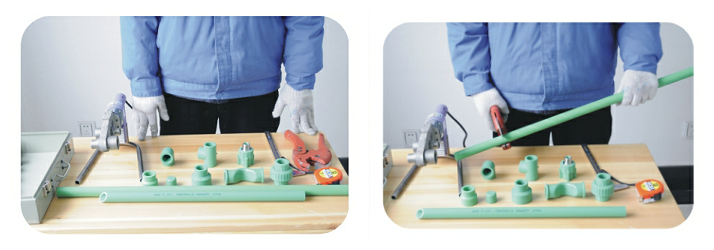

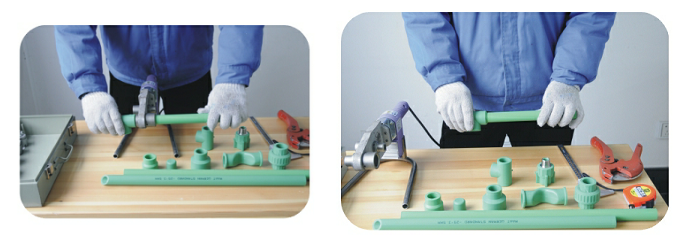

Installation Manual

1. Please make sure that the welding machine has been heated to 260°C, the thermostatic lamp is turned off, and the welding tools are clean.

2. Use PPR scissors to cut the pipe along the axis perpendicular to the pipe.

3. Push the pipe and fittings towards the special welding tool, after you hear the sound and see the material pass through the small hole at the end of the ERA special welding machine, remove the pipe and fittings.

4. Take the pipes and fittings out of the welding machine, connect them immediately. Do not twist pipes and fittings while

welding.

4. Take the pipes and fittings out of the welding machine, connect them immediately. Do not twist pipes and fittings while

welding.

Hot Searches