- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

According to matched equipment

-

Dimension(L*W*H):

-

19*7*8 m

-

Weight:

-

120000 kg

-

Features:

-

Durable,Environmental

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Type:

-

Full-automatic

-

Technology:

-

Thermal Oil Furnace

-

Raw material:

-

Natural Gypsum Ore

-

Working condition:

-

Stable and safe

-

Advantage:

-

Low Energy Consumption,Durable,Full-Automatic

-

Fuel:

-

Oil Gas Coal

-

Price:

-

Competitive

-

Experience:

-

Over 20 years

-

Structure:

-

Simple

Quick Details

-

Application:

-

Make Gypsum Powder

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dafu

-

Voltage:

-

380V

-

Power:

-

According to matched equipment

-

Dimension(L*W*H):

-

19*7*8 m

-

Weight:

-

120000 kg

-

Features:

-

Durable,Environmental

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Type:

-

Full-automatic

-

Technology:

-

Thermal Oil Furnace

-

Raw material:

-

Natural Gypsum Ore

-

Working condition:

-

Stable and safe

-

Advantage:

-

Low Energy Consumption,Durable,Full-Automatic

-

Fuel:

-

Oil Gas Coal

-

Price:

-

Competitive

-

Experience:

-

Over 20 years

-

Structure:

-

Simple

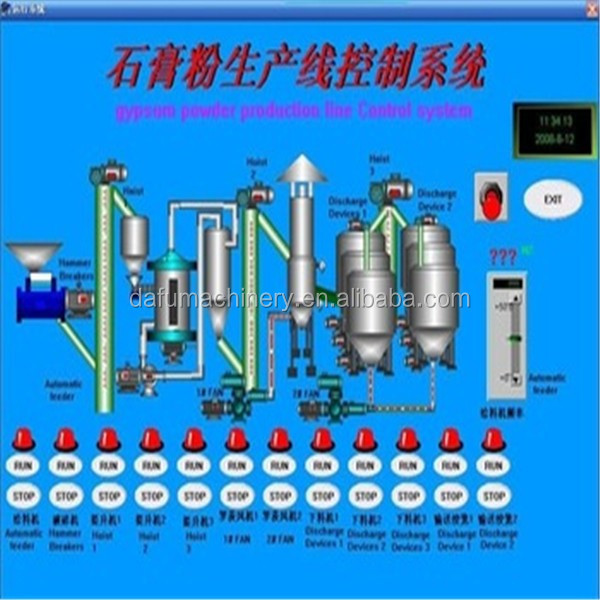

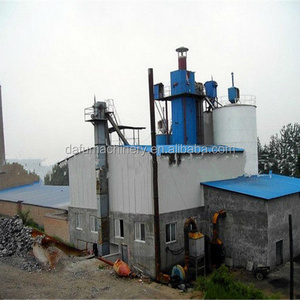

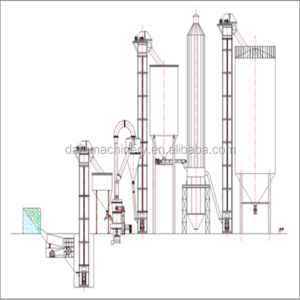

Reliable quality Durable Gypsum Powder Production Line Equipment

Gypsum powder production line

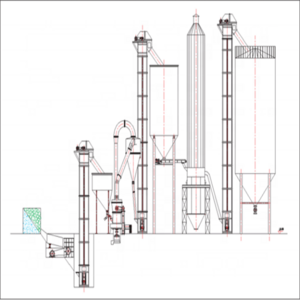

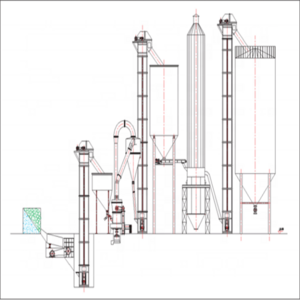

Gypsum powder production line has the features of Low investment, short construction period. It is a new type production line.With the development of gypsum industry, there is a large demand for quantity and high quality of gypsum powder. Therefore, the high level of gypsum powder production technology is required. In the process of gypsum powder production, drying and dewatering is the key link, which is also the most difficult one to control. In order to solve this problem, we develop a new type of drying and dewatering equipment--ebullience calciner, which is produced based on the exploring of the gypsum production filed.

The ebullience calciner

Durable is the main advantage of the ebullience calciner. Structure is simple and hard to destroy. Owing to the fluidization of the materials, rotating parts are not needed and the structure is much simpler, which is convenient for manufacturing and maintenance is not required after put into production. Since the low-temperature heat source is adopted, the furnace shall not be threatened by burning at all events and the equipment has a long service life.

http://dafumachinery.en.alibaba.com/