- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customers Local Voltage

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

4600

-

Equipment Name:

-

AlTiN, AlCrN, AlTiSiN, DLC PVD Coating Machine

-

Application:

-

Surface Treatment / Functional PVD hard coatings

-

Coating film:

-

TIN TIC CrN ZrN TICN

-

Coating color:

-

PVD coating colors

-

Coating Technology:

-

Magnetron sputtering + arc deposition

-

Raw material:

-

Chrome, titanium, silver, etc

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE

Quick Details

-

Machine Type:

-

PVD vacuum coating machine - Arc deposition, Coating Equipment

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Hongfeng VAC

-

Voltage:

-

Customers Local Voltage

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

4600

-

Equipment Name:

-

AlTiN, AlCrN, AlTiSiN, DLC PVD Coating Machine

-

Application:

-

Surface Treatment / Functional PVD hard coatings

-

Coating film:

-

TIN TIC CrN ZrN TICN

-

Coating color:

-

PVD coating colors

-

Coating Technology:

-

Magnetron sputtering + arc deposition

-

Raw material:

-

Chrome, titanium, silver, etc

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE

Vacuum Spraying Installation AlTiN, AlCrN, AlTiSiN, DLC PVD Coating Machine

Applications:

Technical Parameter

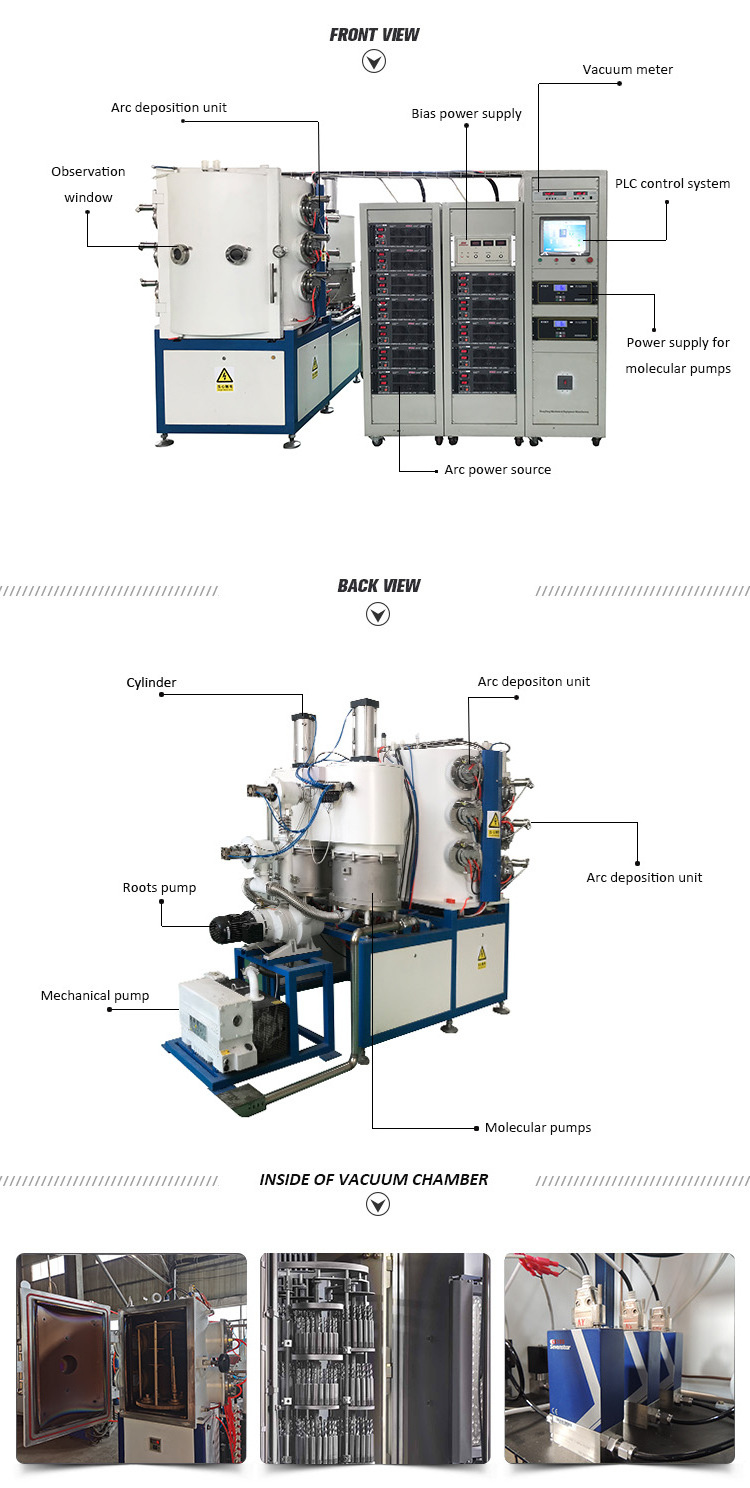

Vacuum PVD chamber Custom made, by Hongfeng VAC

Vacuum pumping system Diffusion pump/Molecular pumps + Roots pump + Mechanical Pumps

Coating system Arc ion plating/deposition system or hybrid technologies

Working Temperature Up to 550 centigrade

Controlling system Touched screen PLC automatic controlling system

Arc Power supply Arc inverter and bias power supply

Water recycling system For the diffusion pump and cathodes

Pretreatment machine Air Compressor, Chiller, Ultrasonic Washer, Pure Water Machine, High Purity Gases

Dimensional Please contact us for your own solution

Power supply 380V/50Hz/60Hz/60A

General Description:

Arc deposition PVD coating equipment is capable to do depositions of many metals on different metals, ceramic and glass substrates.

The PVD coating machine is particularly designed for protective hard coatings on tools, cutter and moulds. It improves the lifetime of different types of tool, meantime, it can increases the surface hardness.

The metal ions combine with a reactive gas that is introduced into the chamber, strike the target tools or components with high energy and are deposited as a thin and highly adherent coating.

Coatings:

| COMMON COATINGS | ||

|

Coating

|

Features

|

Application

|

|

TiN

|

Universal hard coating

|

It is mainly used as durable coating of turning, milling, drilling and gear cutting tools as well as the anti-adhesion of forming of forming and injection molds to improving lubricity.

|

|

TiCN

|

Low Friction Coefficient and Excellent Hardness

|

|

|

TiAlN

|

Universal Anti-Oxidation hard coating

|

With good red hardness and great surface smoothness, it can be used for high speed processing. Also, it is suitable for die steel, HSS, cement carbide tools (hardness of work material is lower than HRC45), stamping dies.

|

|

CrN

|

Universal anti-corrosion hard coating, Low adherence tendency

|

|

|

AlTiN

|

Ultra-high hardness, Anti- Oxidation

|

With very high micro-hardness and hot hardness, it is suitable for tool coatings with high thermal stress. It also has good thermal shock resistance and applicable for cement carbide tools (hardness of work material is lower than HRC45), die-casting molds.

|

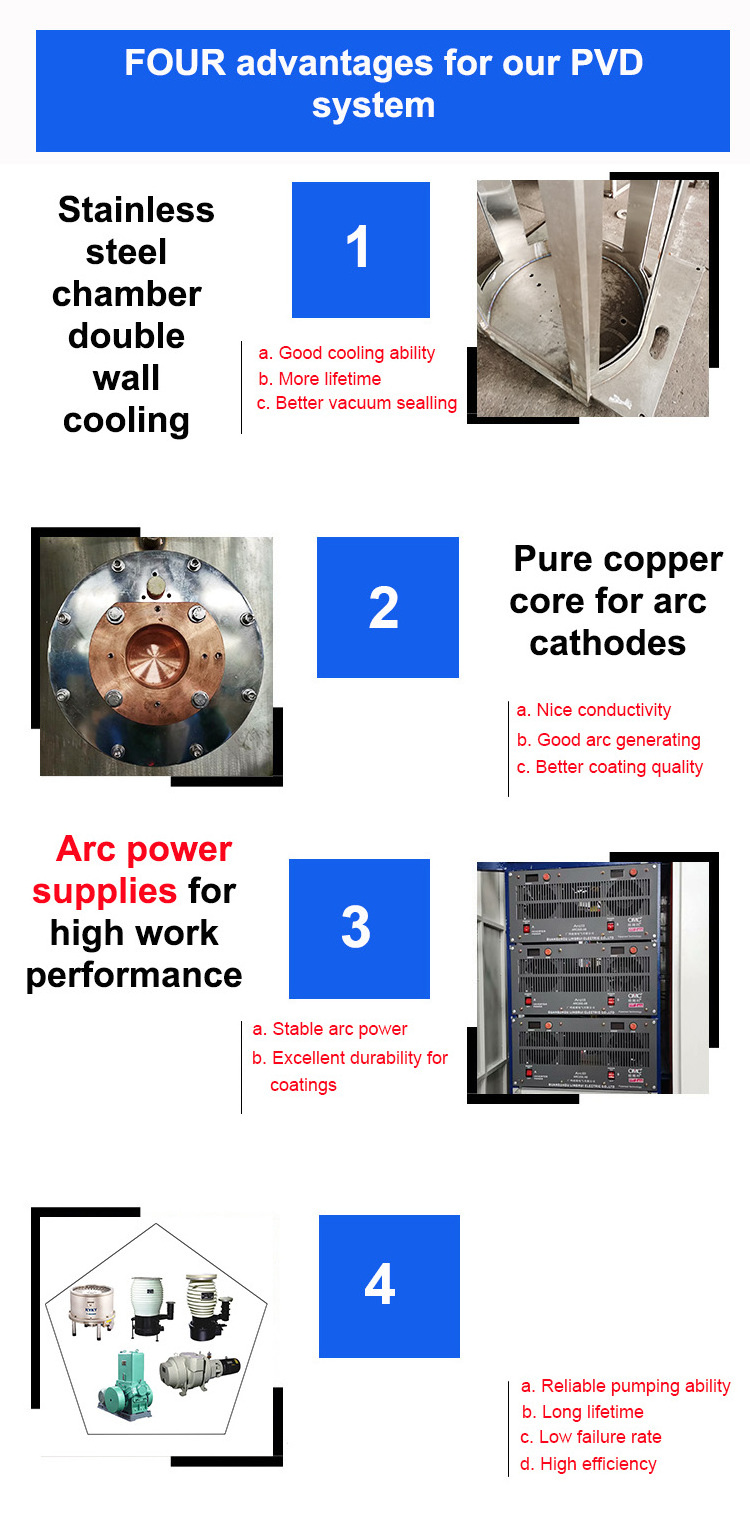

You will need some necessary parts for daily production, we can also provide:

· Vacuum pumps

· Arc sources with arc power supplies

· O rings

· Vacuum meter with gauges/sensors

· Bias power supply

· Magnetic valves

· MFC

· Heating elements

· Target materials

· Customized jigs

Applications

Complete Process: