- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhongxiang

-

Outer Diameter:

-

6 - 2500 mm

-

Thickness:

-

1-150mm(SCH10-XXS) as required

-

Grade:

-

10-45#,16MN,A53(A,B),Q345-Q195 ST35,-ST52.4, Grade AGradeB, Grade C

-

Product name:

-

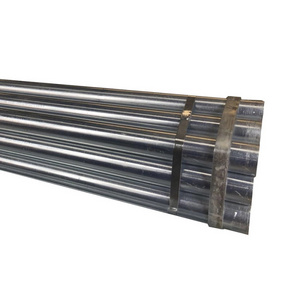

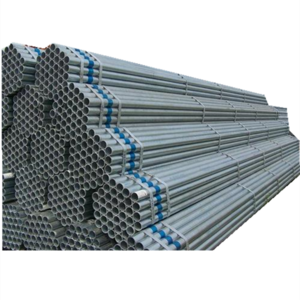

100mm high tensile galvanised steel pipe

-

Features:

-

Corrosion resistance, oxidation resistance, wear resistance,machinable

-

Technique:

-

Hot Dip GalvanizedHot Rolled,Cold Rolled

-

Pipe ends:

-

plastic caps on both ends

-

zinc coating:

-

40-600g/m2

-

advantage:

-

Longer Life Time,Mechanical properties meet standards

Quick Details

-

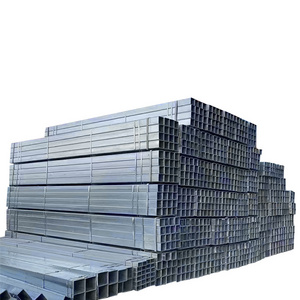

Section Shape:

-

Round

-

Surface Treatment:

-

galvanized

-

Tolerance:

-

±5%, ±1%

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhongxiang

-

Outer Diameter:

-

6 - 2500 mm

-

Thickness:

-

1-150mm(SCH10-XXS) as required

-

Grade:

-

10-45#,16MN,A53(A,B),Q345-Q195 ST35,-ST52.4, Grade AGradeB, Grade C

-

Product name:

-

100mm high tensile galvanised steel pipe

-

Features:

-

Corrosion resistance, oxidation resistance, wear resistance,machinable

-

Technique:

-

Hot Dip GalvanizedHot Rolled,Cold Rolled

-

Pipe ends:

-

plastic caps on both ends

-

zinc coating:

-

40-600g/m2

-

advantage:

-

Longer Life Time,Mechanical properties meet standards

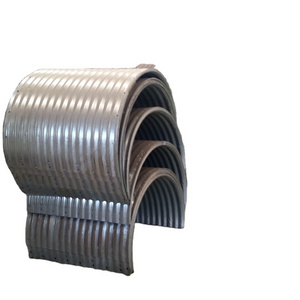

Underground Bunker Corrugated Metal culvert hdg GI Pre Carbon Hot Dip Galvanised Round Steel tipe Tube For Construction

Products Description

The molten metal reacts with the iron matrix and produces an alloy layer, so as to combine the matrix and the coating. Hot dip galvanizing is the first steel pipe pickling, in order to remove iron oxide on the surface of the steel pipe, pickling, through ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank for cleaning, and then into the hot dip plating tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life.

|

Product Name

|

Galvanized Steel Pipe

|

|

Material

|

10#, 20#, 45#, 16Mn, A53(A,B), Q235, Q345, Q195, Q215, St37, St42, St37-2, St35.4, St52.4, ST35

|

|

Wall Thickness

|

1MM~150MM

|

|

Outer Diameter

|

6MM~2500MM

|

|

Length

|

5m-14m,5.8m,6m,10m-12m,12m or as customer's actual reques

|

|

Standard

|

API5L,ASTM A53-2007,ASTM A671-2006,ASTM A252-1998,ASTM A450-1996,ASME B36.10M-2004,ASTM A523-1996,BS EN10296,BS6323,BS 6363

|

|

Grade

|

10#-45#, 16Mn, A53-A369, Q195-Q345, ST35-ST52

Grade A, Grade B, Grade C |

|

Technique

|

Hot Dip Galvanized Round Steel Pipe

|

|

Packing

|

Bundle, or with all kinds of colors PVC or as your requirements

|

|

Pipe Ends

|

Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded and coupling,etc.

|

|

Surface Treatment |

1. Galvanized

2. PVC,Black and color painting 3. Transparent oil,anti-rust oil 4. According to clients requirement |

|

DN

|

inch

|

outer diameter mm

|

wall thickness mm

|

min wall thickness mm

|

weight per meter kg

|

Each weight kg

|

Each weight kg

|

weight per meter kg

|

|

DN15

|

1/2

|

21.3

|

2.8

|

2.45

|

1.28

|

7.68

|

1.357

|

8.14

|

|

DN20

|

3/4

|

26.9

|

2.8

|

2.45

|

1.66

|

9.96

|

1.76

|

10.56

|

|

DN25

|

1

|

33.7

|

3.2

|

2.8

|

2.41

|

14.46

|

2.554

|

15.32

|

|

DN32

|

1.25

|

42.4

|

3.5

|

3.06

|

3.36

|

20.16

|

3.56

|

21.36

|

|

DN40

|

1.5

|

48.3

|

3.5

|

3.06

|

3.87

|

23.22

|

4.10

|

24.60

|

|

DN50

|

2

|

60.3

|

3.8

|

3.325

|

5.29

|

31.74

|

5.607

|

33.64

|

|

DN65

|

2.5

|

76.1

|

4.0

|

3.5

|

7.11

|

42.66

|

7.536

|

45.21

|

|

DN80

|

3

|

88.9

|

4.0

|

|

8.38

|

50.28

|

8.88

|

53.28

|

|

DN80

|

4

|

114.3

|

4.0

|

|

10.88

|

65.28

|

11.53

|

69.

|

Product Show

1. Black parts inspection → hanging material → degreasing → rinsing → pickling → cleaning → dipping agent → hot air drying → hot dip galvanizing → inside and outside blowing → cooling → passivation and rinsing → unloading → inspection, dressing → typing labeling → packing into storage and transportation.

Galvanized strip → uncoiling → stretching → rolling → welding → scraping → passivation and rinse → zinc filling → shaping → typing mark → cutting → packing → drying → weighing.

Galvanized strip → uncoiling → stretching → rolling → welding → scraping → passivation and rinse → zinc filling → shaping → typing mark → cutting → packing → drying → weighing.

1. Low processing cost: the cost of hot-dip galvanized rust prevention is lower than that of other paint coatings.

2, good reliability: the durability of the coating is more reliable.

3, durable: hot dip galvanized steel pipe with surface gloss, uniform zinc layer, no leakage plating, no dripping, adhesion strong break net corps, strong corrosion resistance characteristics, in the suburban environment rose significantly, the standard hot dip galvanized rust thickness can be maintained for more than 50 years without repair; In urban and offshore areas, standard hot-dip galvanized rust protection can be maintained for 20 years without repair.

3, durable: hot dip galvanized steel pipe with surface gloss, uniform zinc layer, no leakage plating, no dripping, adhesion strong break net corps, strong corrosion resistance characteristics, in the suburban environment rose significantly, the standard hot dip galvanized rust thickness can be maintained for more than 50 years without repair; In urban and offshore areas, standard hot-dip galvanized rust protection can be maintained for 20 years without repair.

4, the toughness of the coating is strong: the galvanized layer forms a special metallurgical structure, which can withstand

mechanical damage during transportation and use.

5, comprehensive protection: every part of the plated parts can be plated with zinc, even in the depression, sharp corners and hidden places can be fully protected.

6, save time and effort: galvanizing process is faster than other coating construction method

mechanical damage during transportation and use.

5, comprehensive protection: every part of the plated parts can be plated with zinc, even in the depression, sharp corners and hidden places can be fully protected.

6, save time and effort: galvanizing process is faster than other coating construction method

Application

Widely used in conveying gas, heating, Construction, machinery, coal mine, chemical industry, electric power

(1)Quality Zhongxiang steel introduces the advanced testing equipments and builds up a professional scientific research team, strictly control the quality on each steps of production. including inspection on raw materials entry, product's color analysis during production,T-bend test, impact test, salt-spray test, tensile test and packaging testing on exported products , which ensures its integrated performance such as corrosion resistance, coating stickiness etc and the safety of transportation.

(2)Service Nowadays, the economic globalization is facilitating international operation, our company go to many countries and regions to participate in the steel industry exhibition. our Products sell pretty well not only in domestic market, but also prevails in Europe,such as southeast Asia, Russia, Ukraine, the United States, Ireland, Singapore, Dubai, Colombia and other countries and regions, which has earned the customers trust & compliment and successfully transitioned from home to abroad.

Hot Searches