3.The advantages of our products

1). High quality material for the base shaft and spare parts

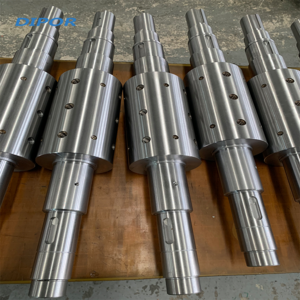

The body of the differential shaft is made from steel or stainless steel.We will check the surface roughness,straightness, dynamic

balance,cylindrical and so on to make sure it's qualified to use.

The friction plate can be made from polyurethane, polyethylene,or rubber.They has good consistency of dynamic and static friction

coefficient, less affected by temperature ,high wear resistance and long service life.It's good to realize max tension

required.And we can customize according to customer’s drawing or special requirement.

2).Surface Treatment

Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting.

The overall quenching and tempering treatment improve the wear resistance and corrosion resistance,which make it possible to use in a variety of environment.

3). Quality control

We have the quality control system during the whole production from the very beginning to the end and our principle is to make

sure each shaft is qualified.