Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

225mm

-

Specification:

-

40-630mm

-

Length:

-

1-6m

-

Thickness:

-

2.4-30mm

-

Standard:

-

ISO9001, API

-

Product name:

-

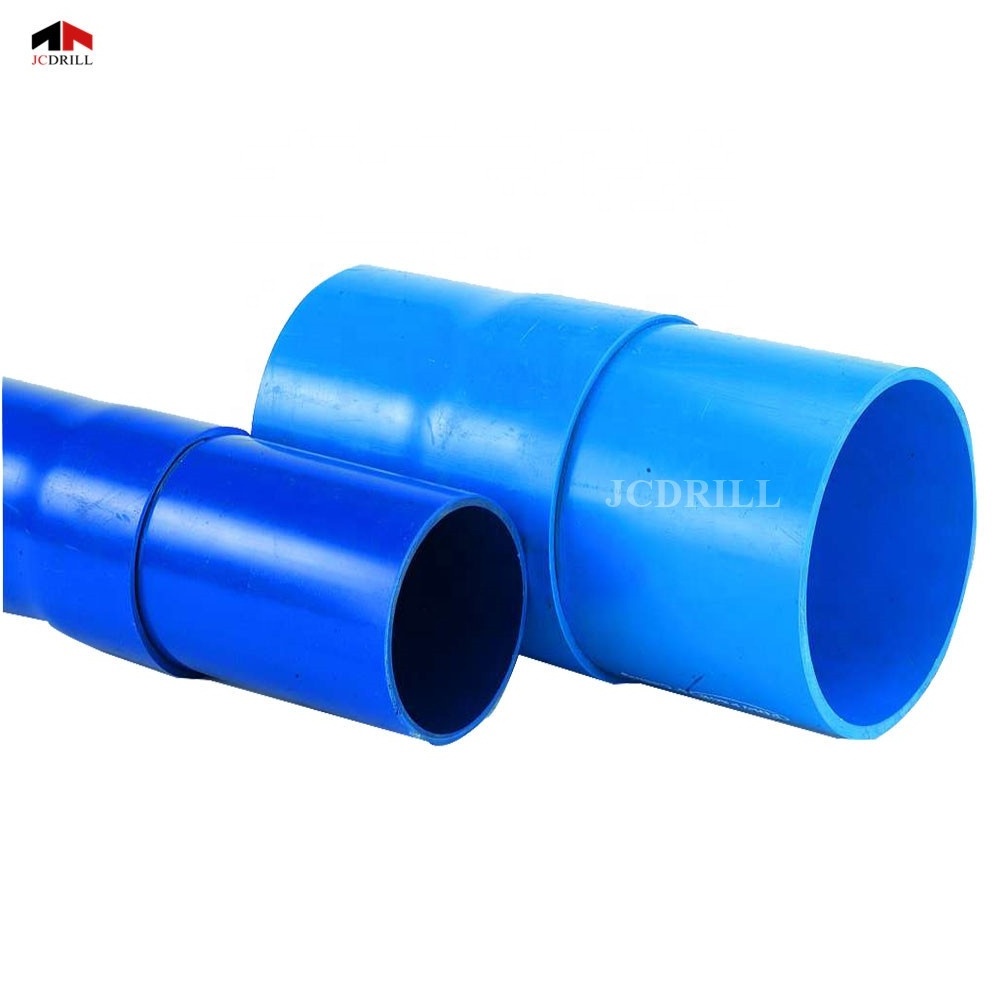

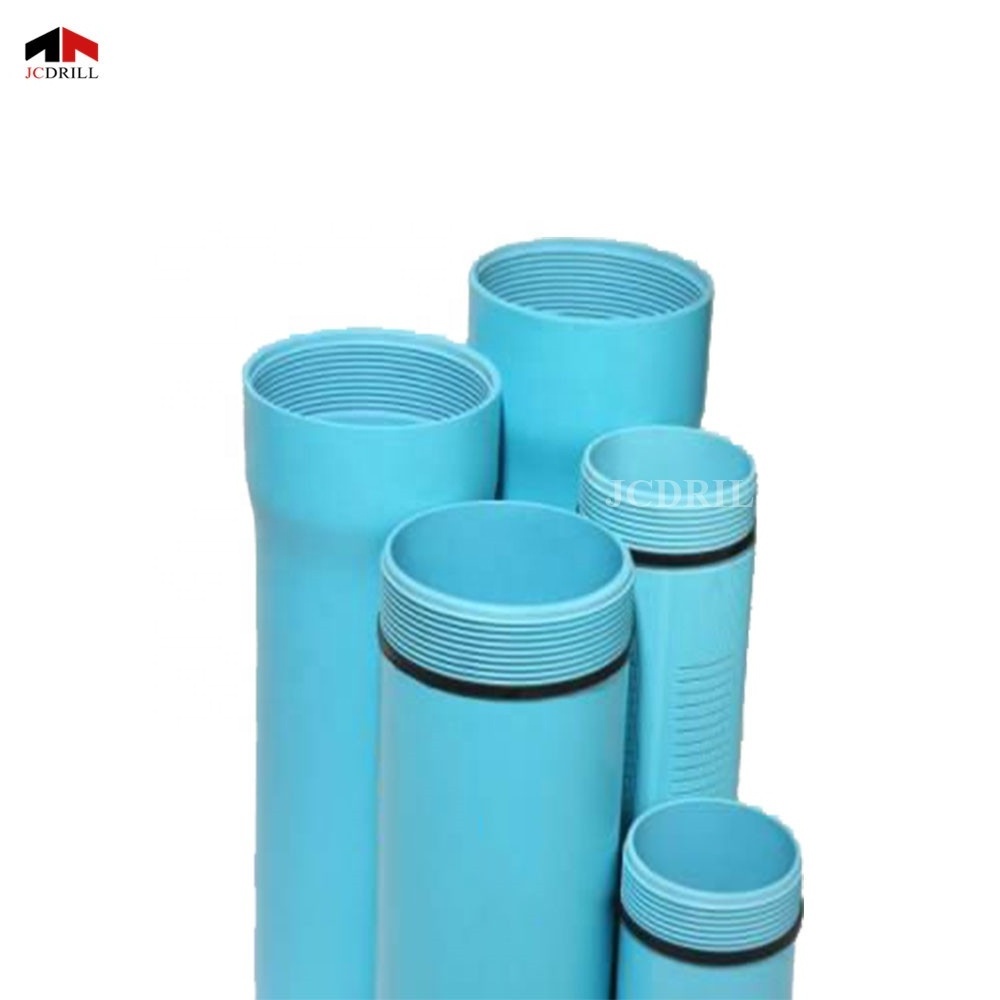

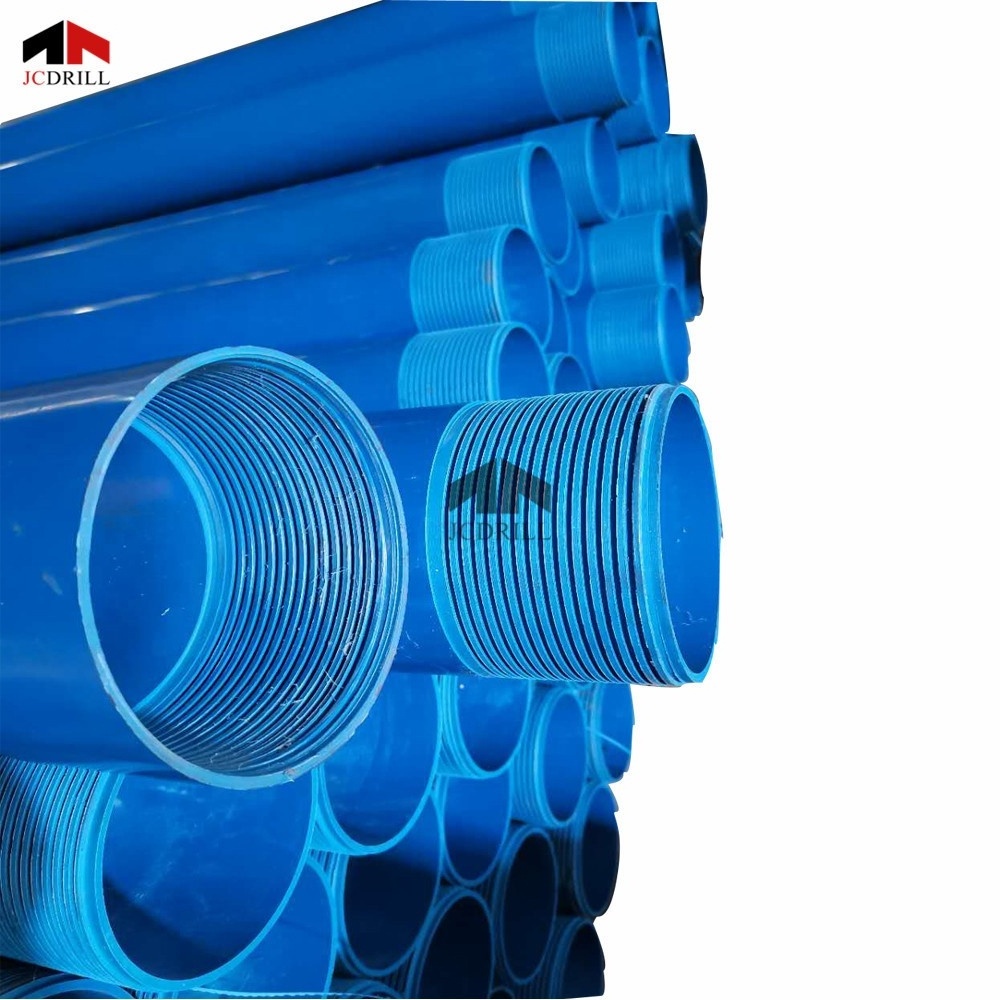

PVC casing and screen pipes

-

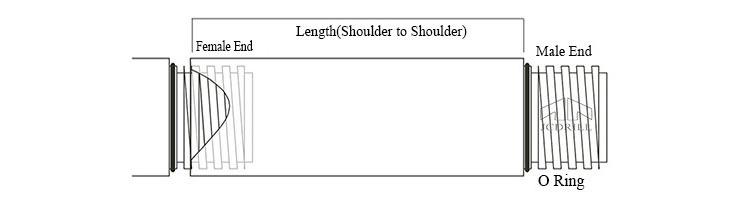

End connection:

-

Thread or Socket

-

Outer Diameter:

-

40-630mm

-

Application:

-

Water well drilling casing

-

Certification:

-

ISO,CE

-

Section Shape:

-

Round

-

Thread:

-

LTC,STC,BTC,VAM

-

type:

-

pvc well casing and screen pipes

Quick Details

-

Processing Service:

-

Cutting

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

JCDRILL

-

Model Number:

-

225mm

-

Specification:

-

40-630mm

-

Length:

-

1-6m

-

Thickness:

-

2.4-30mm

-

Standard:

-

ISO9001, API

-

Product name:

-

PVC casing and screen pipes

-

End connection:

-

Thread or Socket

-

Outer Diameter:

-

40-630mm

-

Application:

-

Water well drilling casing

-

Certification:

-

ISO,CE

-

Section Shape:

-

Round

-

Thread:

-

LTC,STC,BTC,VAM

-

type:

-

pvc well casing and screen pipes

20-315mm DIN UPVC Pipe Industrial PVC Pipe Water Pipe Fitting Plastic Tube Connector For Water Supply

u-pvc 140mm high quality casing pipe and screen casing of water well drilling

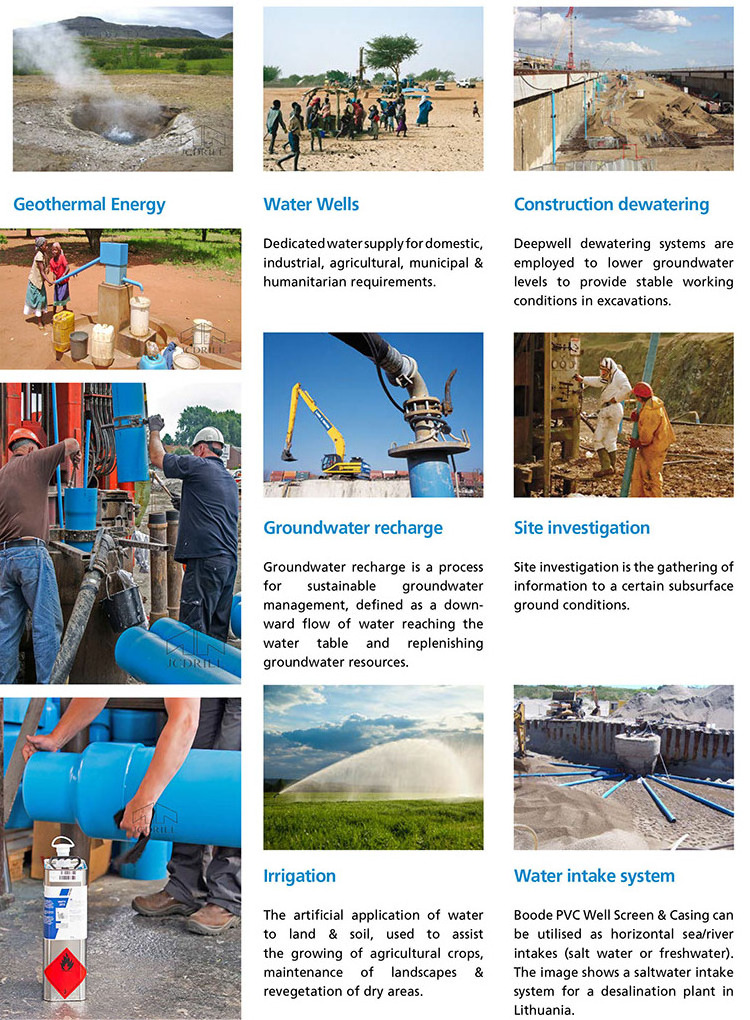

Application

Specification

| Size(Out Diameter) | (0.80 Mpa) | (1.0 Mpa) | (1.25 Mpa) | (1.6 Mpa) | (2.0 Mpa) | ||||||

| mm | Inch | Weight | Thickness | Weight | Thickness | Weight | Thickness | Weight | Thickness | Weight | Thickness |

| Kgs/m | mm | Kgs/m | mm | Kgs/m | mm | Kgs/m | mm | Kgs/m | mm | ||

| 40 | 1.25 | 0.41 | 2 | 0.47 | 2.4 | 0.56 | 3 | 0.68 | 3.7 | ||

| 50 | 1.5 | 0.5 | 2 | 0.58 | 2.4 | 0.72 | 3 | 0.85 | 3.7 | 1.06 | 4.6 |

| 63 | 2 | 0.79 | 2.5 | 0.95 | 3 | 1.15 | 3.8 | 1.41 | 4.7 | 1.68 | 5.8 |

| 75 | 2.5 | 1.07 | 2.9 | 1.3 | 3.6 | 1.63 | 4.5 | 1.9 | 5.6 | 2.39 | 6.9 |

| 90 | 3 | 1.53 | 3.5 | 1.88 | 4.3 | 2.33 | 5.4 | 2.8 | 6.7 | 3.41 | 8.2 |

| 110 | 4 | 1.87 | 3.4 | 2.23 | 4.2 | 2.82 | 5.3 | 3.4 | 6.6 | 4.2 | 8.1 |

| 125 | 4.5 | 2.41 | 3.9 | 2.95 | 4.8 | 3.33 | 6 | 4.44 | 7.4 | 5.4 | 9.2 |

| 160 | 6 | 3.89 | 4.9 | 4.8 | 6.2 | 5.97 | 7.7 | 7.24 | 9.5 | 8.87 | 11.8 |

| 200 | 8 | 6.14 | 6.2 | 7.3 | 7.7 | 9.31 | 9.6 | 11.19 | 11.9 | 13.84 | 14.7 |

| 225 | 9 | 7.69 | 6.9 | 9.1 | 8.6 | 11.97 | 10.8 | 14.41 | 13.4 | 17.53 | 16.6 |

| 250 | 10 | 9.51 | 7.7 | 11.4 | 9.6 | 14.4 | 11.9 | 17.7 | 14.8 | 21.61 | 18.4 |

| 280 | 11 | 11.88 | 8.6 | 14.7 | 10.7 | 18.2 | 13.4 | 22.19 | 16.6 | 27.08 | 20.6 |

| 315 | 12 | 15.09 | 9.7 | 18 | 12.1 | 22.89 | 15 | 28.17 | 18.7 | 34.31 | 23.2 |

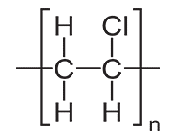

Material

PVC-U , unplasticised polyvinyl chloride is an ideal material for manufacturing well pipes as it is impervious to corrosion and chemical action, easy to handle and install, light in weight, non-toxic, and non-conductive. Its long service life makes it an economical choice over other materials.

Technology Design

1. Discharge Pipe Well Head

2. Concrete Slab For The Well House Foundations

3. PVC Pump Chamber Casing

4. Pumping Water Level In The Borehole

5. Cement Or Bentonite Grout Sealing The Annulus Around The Pump Chamber Casing

6. Electric Submersible Pump

7. Water Inflow To The Pump Intake

8. PVC Well Screen

9. Gravel Filter Pack Filling The Annulus Around The Well Screen

10. Groundwater Is Drawn Through The Screen Slots And Flows Up To The Pump Intake

11. Groundwater Flows Through The Sand And Gravel Aquifer To The Well Screen

Advantages

Pictures

Tensile Strength

The tensile strength required can be calculated on the basis of pipe weight. In addition to the pipe weight, gravel that gets stuck in the joints during the assembly and settlement phase should be considered in design calculations. The lower load bearing capacity of screen pipes with slots should be considered when developing the well or when pumping (due to large differences in water level). The effect of such pressures cannot be precisely determined. When sinking pipes through clay layers, additional compressive forces are exerted due to swelling clays. This can happen at any depth and in extreme cases may cause considerable strain on the material surface. The values indicated in the tables of this brochure are based on the minimum wall thickness of the pipes, their diameters and material composition.

Impact of Temperature

Temperature conditions prevailing during the laying of PVC-U well pipes will influence the mechanical properties of the material. High temperature between 30° C and 40° C as indicated by the creep strength in relation to time, the PVC-U material properties provide sufficient safety factor for the intended use. It is however important to determine the other influences while encasing the well pipes with concrete to seal the drill holes. Temperature increases can be caused by the hydration heat of concrete. Calculations however show that these temperatures do not normally exceed 15°C. With the temperature of unset concrete reaching approx. 18°C, the temperature within the seal will be slightly more than 30°C and that is within the optimum limits.

Packaging & Delivery

FAQ

Q: Are you original manufacturer?

A: Yes, we JCDRILL is a official leading manufacture in drilling machinery in China and we have

the whole series products you need.

Q: Which payment terms are available to us?

A: T/T term or L/C term. On T/T term, 30% down payment is required in advance, and 70% balance shall be settled before shipment.On L/C term, a 100% irrevocable L/C without "soft clauses" can be accepted.

Q: How long will the delivery time take?

A: Normally mud pump products will take about 3-15 days to produce the ordered machines. Most of the time, we can have an immediate delivery of our regular machines in 15 days.

Q: How about after sales service?

A: 365×24 Year-round Service We are committed to year-round 24-hour service even during holidays, in line with our policy of always providing "a response within 15 minutes and job completion within 24 hours."

Q: Spare parts when you need them?

A:We have spare parts centers across continents that stock specialist spare parts. We promise that spare parts will be delivered within 72 hours or no more than one week.

Related Products