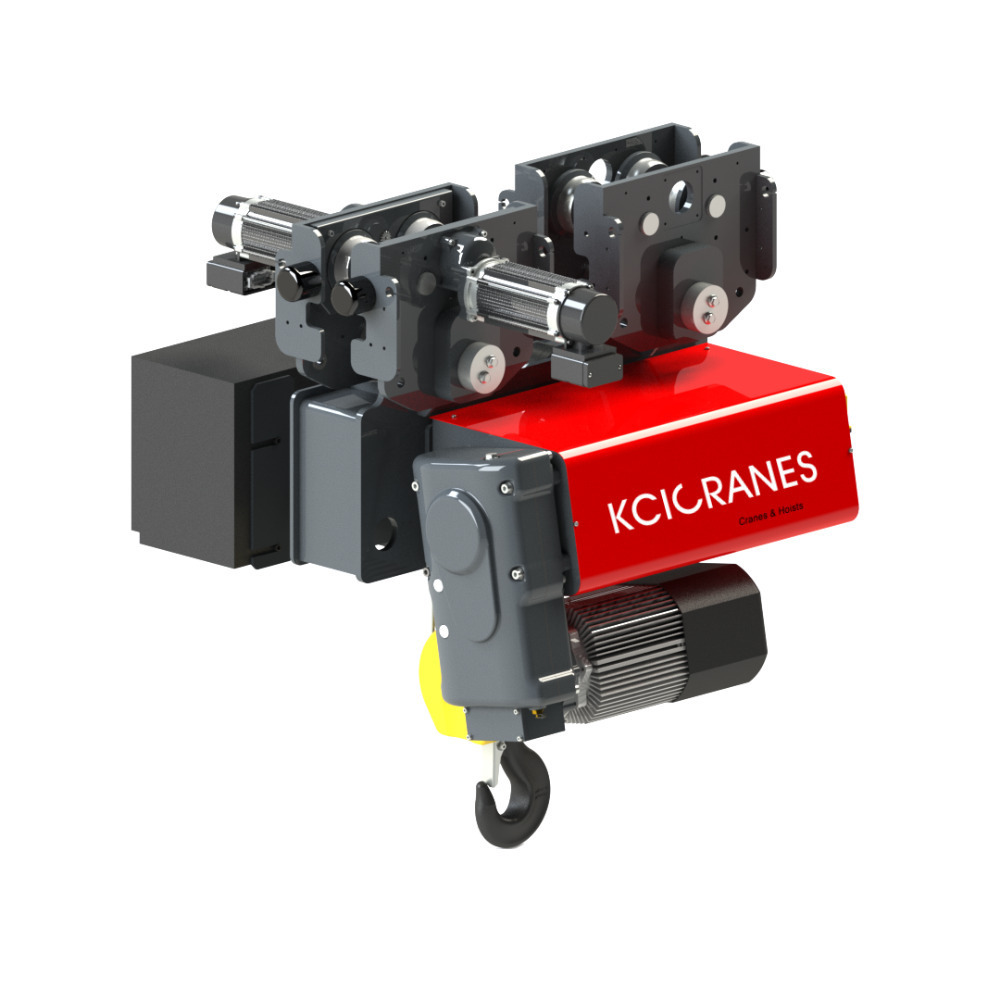

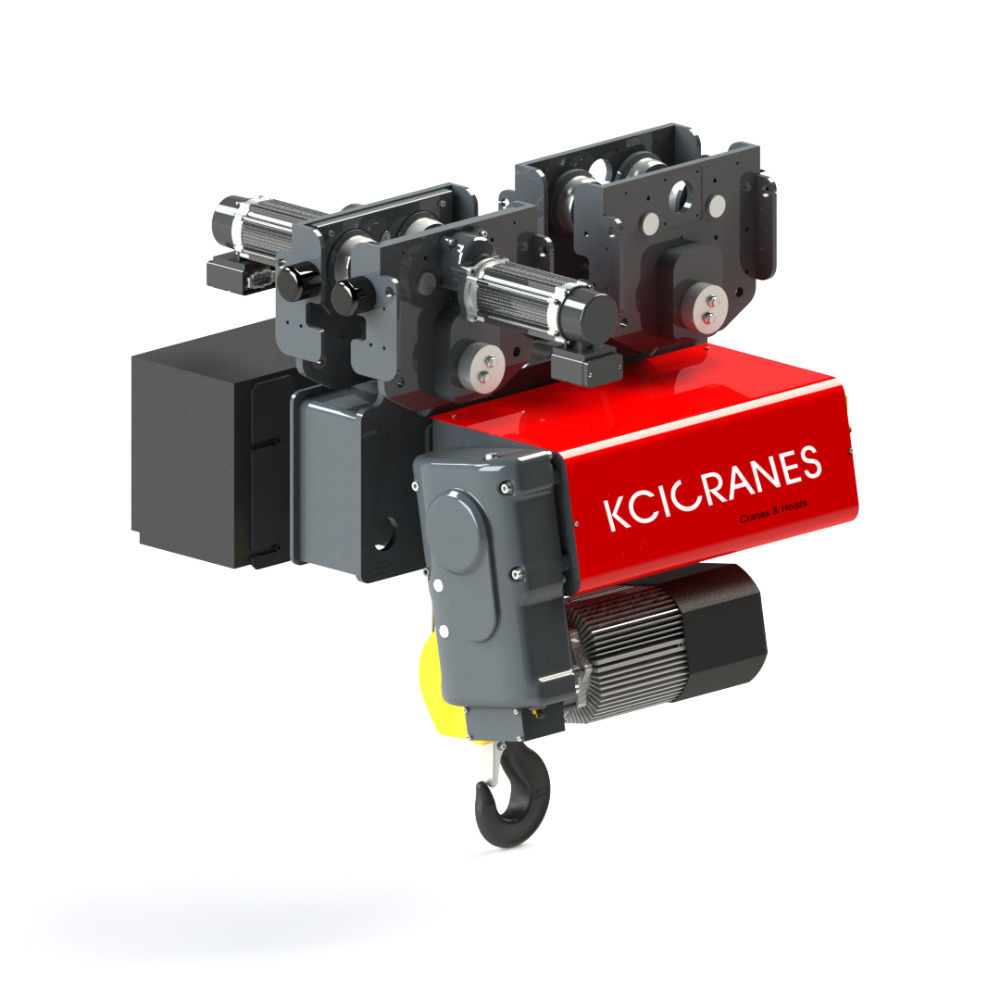

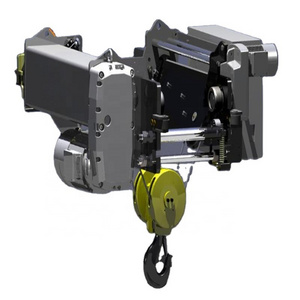

The electric hoist is often mounted on a beam or trolley to provide horizontal movement as well as vertical lifting. It is a versatile and efficient tool for handling heavy loads, and it can improve productivity and safety in material handling operations.

Overall, electric hoists play a crucial role in various industries by providing a reliable and controlled method for lifting and positioning heavy items.

The lifting capacity and lifting height can be customized.Welcome to send a free inquiry to KCICRANES.