Option B: If You Need The Fully Automatic Hydraulic 3 Ton, We Can Change For You. The Price Is 4800 Usd More.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

Other

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380v/50hz/3p (As Requested)

-

Dimension(L*W*H):

-

9*1.5*1.5m

-

Weight:

-

6500 kg

-

Marketing Type:

-

New Product

-

Advantage:

-

Easy installation and operation

-

After-sales Service:

-

Provided Lifetime technical service

-

Local service:

-

Provide Engineers door-to-door service

-

Certification:

-

CE ISO

-

Raw material:

-

PPGI,PPGL

-

Material of rollers:

-

GCr12 MOV

-

Material of shafts:

-

45# steel Tampering treatmen

-

Cutting type:

-

Hydraulic track cutting

Quick Details

-

Type:

-

door frame making machine

-

Tile Type:

-

GI GL

-

Production Capacity:

-

Other

-

Rolling thinckness:

-

Other

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380v/50hz/3p (As Requested)

-

Dimension(L*W*H):

-

9*1.5*1.5m

-

Weight:

-

6500 kg

-

Marketing Type:

-

New Product

-

Advantage:

-

Easy installation and operation

-

After-sales Service:

-

Provided Lifetime technical service

-

Local service:

-

Provide Engineers door-to-door service

-

Certification:

-

CE ISO

-

Raw material:

-

PPGI,PPGL

-

Material of rollers:

-

GCr12 MOV

-

Material of shafts:

-

45# steel Tampering treatmen

-

Cutting type:

-

Hydraulic track cutting

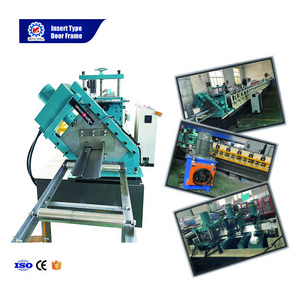

Door Frame Roll Forming Machine

Design Idea:

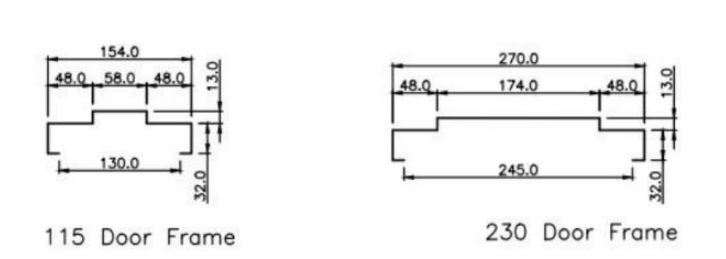

For this machine, the sizes changing are controlled by Changing spacer, and you need to change the cutting blades for these 2 molds: 115 door frame and 230 door frame . By this way, the cutting could be more accurate.According to the Usage of this door frame you need some punching hole on it, including hinge and lock hole.

For this machine, the sizes changing are controlled by Changing spacer, and you need to change the cutting blades for these 2 molds: 115 door frame and 230 door frame . By this way, the cutting could be more accurate.According to the Usage of this door frame you need some punching hole on it, including hinge and lock hole.

|

Description

|

Production Time

|

Delivery Package

|

|

Door Frame Roll Forming Machine

|

40 Working Days

|

40 GP Container

|

Profile drawing for reference:

Raw material: Galvanized steel plate

Material thickness : 0.8mm

Processing Flow

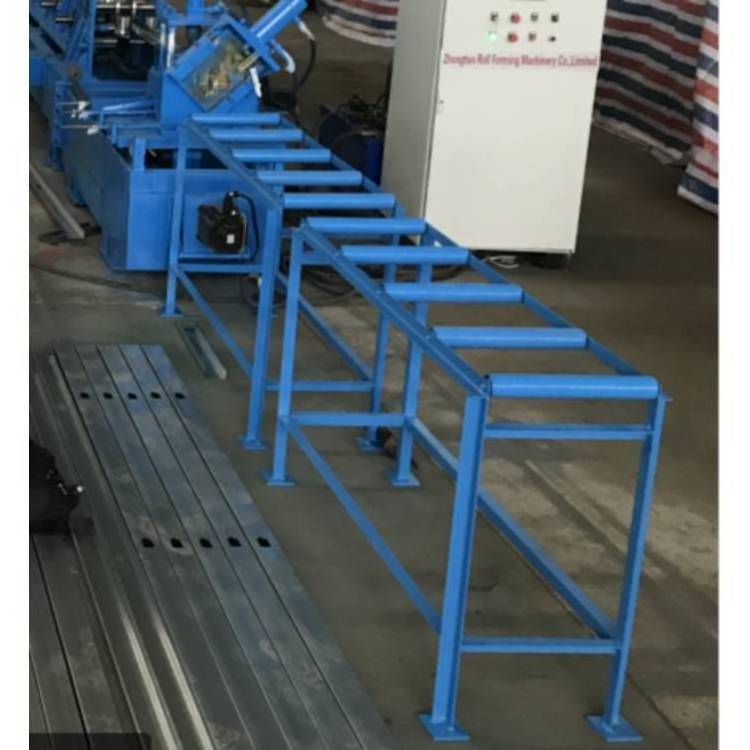

Decoiler System

Usage: It Is Used To Support The Steel Coil And Uncoil It In A Turntable Way. Passive Uncoil Pulled By Roll Forming System.

Loading Capacity: 3 T

Uncoiling Width: 300mm

Inner Diameter: 450-550mm

Feeding Part

Usage: Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity.

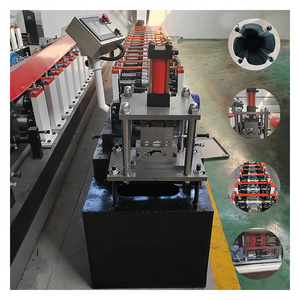

Main Roll Forming System

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, gear transmission, roller surfaces polishing, hard plating, heat treatment and galvanizing treatment.

Material of rollers :GCr15 Quenching treatment HRC55-57°Finishing

Material of shafts : 45# steel with tempering

Diameter of shafts : φ 50 mm

Number of rollers :One set

Main power : 7.5 kw

Forming speed : 0-15m per minute

Base Frame Structure : Plate splicing Overall processing

Weight of main part : 6.5 tons

Voltage : 380V 50Hz 3Phase (as customer request)

Drive mode : Chain and Gear

Shearing Mechanism

Function : Automatic cutting controlled by PLC

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Cutting Blade :GCr12 quenched

Power supply : Hydraulic power

Components : It contains one set of blade, one hydraulic tank and one cutter machine.

Cutting Tolerance : 10M±1.5mm

Frame Structure : A3 Carbon Steel Plates welded & Guide Pillar

Cutting Knife : Inside sealing Cu Spacer, whole life no maintain,only

Products Receiving Tables

Hydraulic station

Usage: It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

Hydraulic motor Power : 5.5 KW(Lichao, Shanghai)

Solenoid Valve : ±24V(Huade,Beijing)

Hydraulic oil : 46# hydraulic oil

Electric Control System

Adopted PLC , transducer, touch panel to ensure high speed with stability, precision and lifetime.

PLC System : Delta PLC Programme,Taiwan

Encoder Brand : Rongde,Changchun

HIM Screen : Detlta,Taiwan (English-Chinese)

Inverter Brand : Delta ,Taiwan

Other Electronic : +/-24V low voltage CHNT

Operating panel : Touching screen and button together

Running mold : Automatic length measurement,Automatic quantity measurement

Hot Searches