- Product Details

- {{item.text}}

Quick Details

-

Application:

-

1812~3013

-

Function:

-

membrane edge cutting

-

Type:

-

disk cutter and shank type cutter optional

-

Certification:

-

CE Certificate

-

Capacity:

-

500~1000pcs

-

Driver:

-

Servo motor

-

Control system:

-

Mitsubishi PLC

-

Feeder:

-

automatic feeder system

-

power:

-

AC 220V / 1KW

-

Air pressure:

-

0.4 ~ 0.7Mpa

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

longsheng

-

Model Number:

-

T-3013

-

Application:

-

1812~3013

-

Function:

-

membrane edge cutting

-

Type:

-

disk cutter and shank type cutter optional

-

Certification:

-

CE Certificate

-

Capacity:

-

500~1000pcs

-

Driver:

-

Servo motor

-

Control system:

-

Mitsubishi PLC

-

Feeder:

-

automatic feeder system

-

power:

-

AC 220V / 1KW

-

Air pressure:

-

0.4 ~ 0.7Mpa

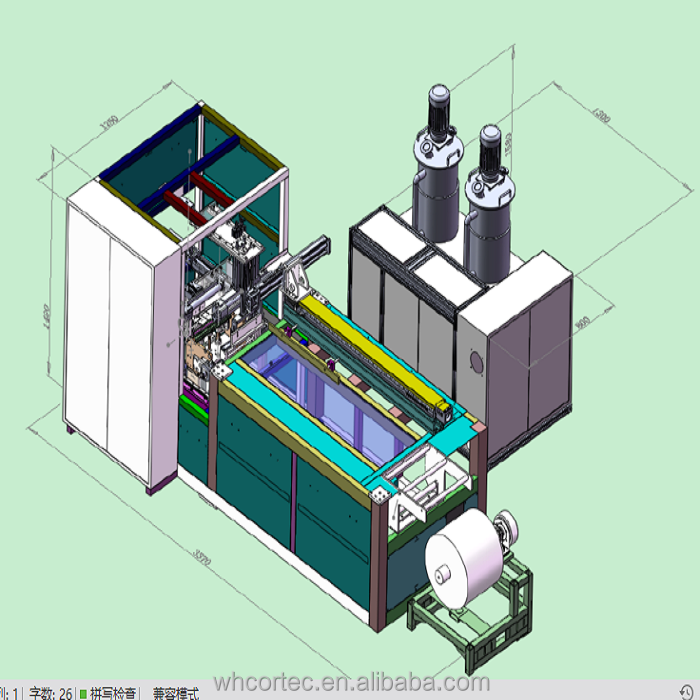

Product Application

The Trimming Machine for RO membrane can achieve the function of cutting down the two side edges and separate them off the RO module, make the RO membrane manufacture process fully automatic and computerized.

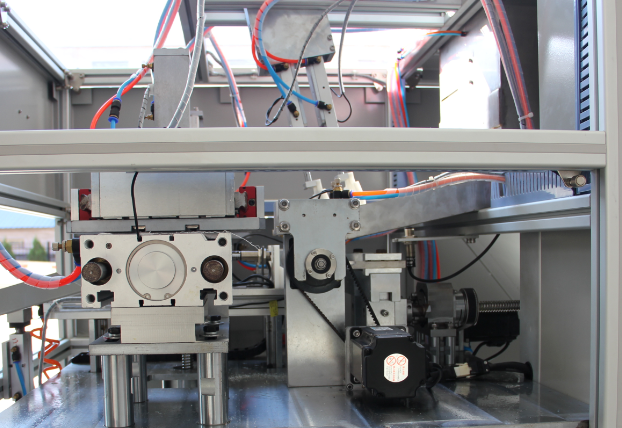

The cutting tool driven by servo motor system to ensure stable quality.

To keep the machine running in safety and easy operation HMI touch screen, PLC system and foot switch adopted.

The optimized designed machine make it good ergonomics, elegant appearance, easy installation and durable working duty.

Main structure:

Main Features

CE certified, machine exported to EU zone

Advantage:

1.High compatibility

The machine is common used for all most all the RO membrane for domestic or household used, such as 1810,1812,2812,3012,3013 available for different width and layers, it is easy to adjust the cutting tool and ensure high productivity.

2.Highly automatic performance

Controlled by computer, the machine is highly automated, the only work handled by hand is to put the folded RO membrane into the feed bin.

3.High yield and qualified rate

With high cutting speed and by adopting precision tools and fixture, the RO rollers are made in high efficiency without burr or uncut edge left, and the center tube not damaged or hurt.

4.High safety and stable

To keep the machine running smoothly and safely, the limit switches, optical sensor monitor and inter-lock system applied to avoid unnecessary hurt or lost.

5.Cost reduce prominent

High efficiency, taking the 1812 for example, it takes 6~10 seconds to fulfill one finished RO module which can match about 4~5 workers, highly reduce the labor strength and intensity.

Machine Drive

Name: cutting system

membrane automatic feeding system ensure the cutting process smoothly and stablely with working at continoius manner.

Eletrical control system

Brand:

Mitsubishi PLC,Omron schineder,LG brand component

brand electrical parts and componants ensure the machine stable working with long life time.

relay pretections wired with key componants to prevent all the key parts in safe from eletrical current or voltage flucturate.

Pre-sale service.

we offer our customer with detialed information about the machines both in terms of technical and commercial to ensure customer fully understand our machine for further smooth coorperation.

After-sale service.

Technicains for installation and try running to customer's factory available at request of customer ,all related cost borne by user(include round air tickets, hotel,food,salary usd80/day/person).

Warranty:

We grant the Buyer 12-months warranty for the Goods.

Within the scope of granted warranty, we are obliged to rectify any faults, which would develop or were found free of charge, within the valid period of warranty.

Warranty does not cover such faults where:

a) storage, operation and maintenance of the Goods, deviate from the generally accepted practice,

b) Normal wear and tear of each elements of the Goods,

c) Repairs, alterations or modifications to the Tools made by the Buyer without written permission by the Seller.