- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HZ SUNPOWER

-

Product Name:

-

Forklift Attachment Drum Clamp

-

Application:

-

Any drums

-

Material:

-

High Stength Steel

-

Main Parts:

-

Oil motor/gear/arm/contact pad

-

Function:

-

Conveying bales type products

-

Color:

-

Customized Color

-

Capacity:

-

200-3000kg

Quick Details

-

Warranty:

-

1 Year

-

Weight (KG):

-

500

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HZ SUNPOWER

-

Product Name:

-

Forklift Attachment Drum Clamp

-

Application:

-

Any drums

-

Material:

-

High Stength Steel

-

Main Parts:

-

Oil motor/gear/arm/contact pad

-

Function:

-

Conveying bales type products

-

Color:

-

Customized Color

-

Capacity:

-

200-3000kg

Product Description

Forklift Drum clamps

Applications

-Forklift Drum clamps are used wherever product is stored in drums, including the petroleum, chemical and food

processing industries.

-Forklift Drum clamps improve productivity by allowing a forklift driver to handle up to four drums per load. In

addition, the use of a drum clamp allows the driver to securely grip the drums for transporting. This eliminates

instability during braking and cornering, which is a common problem when attempting to handle drum with

conventional forks.

Features

-Proven, durable T-beam arm and aluminum frame construction.

-Superior arm-slide material and design for extending service life.

-Arm design for handling standard 55-gallon drums---standard

-Replaceable rubber faced arm pads

-Regenerative hydraulic valving for optimal arm speed

Options

-Custom arm radiuses for special drum sizes -Custom arms for fiber and for plastic drums

-Custom arm lengths -Quick disconnect mounting -Custom opening ranges

-Forklift Drum clamps are used wherever product is stored in drums, including the petroleum, chemical and food

processing industries.

-Forklift Drum clamps improve productivity by allowing a forklift driver to handle up to four drums per load. In

addition, the use of a drum clamp allows the driver to securely grip the drums for transporting. This eliminates

instability during braking and cornering, which is a common problem when attempting to handle drum with

conventional forks.

Features

-Proven, durable T-beam arm and aluminum frame construction.

-Superior arm-slide material and design for extending service life.

-Arm design for handling standard 55-gallon drums---standard

-Replaceable rubber faced arm pads

-Regenerative hydraulic valving for optimal arm speed

Options

-Custom arm radiuses for special drum sizes -Custom arms for fiber and for plastic drums

-Custom arm lengths -Quick disconnect mounting -Custom opening ranges

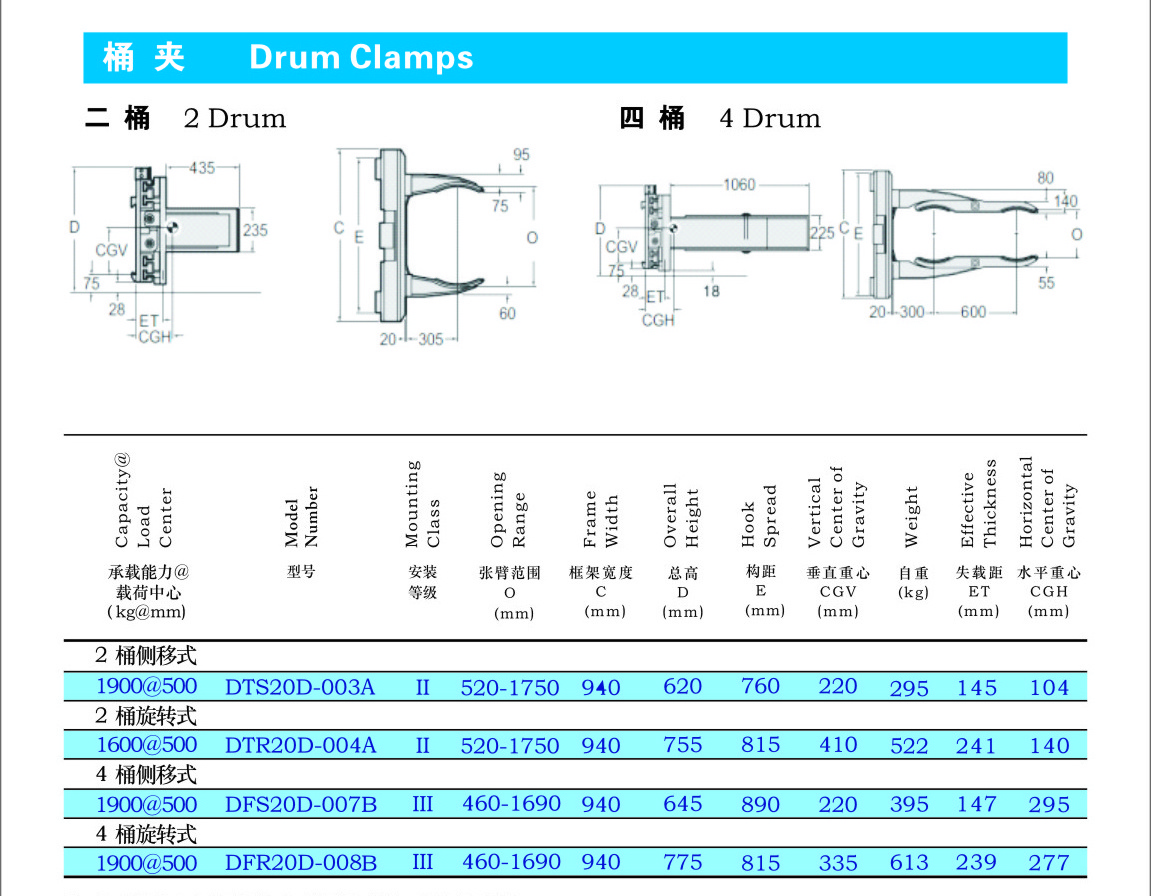

Specification

Forklift Drum clamps

Note: 1) Tow sets additional oil circuit required on forklift

2) Open arm range is the space between two arms tip

3) Arm thickness “D” is the actual requested operation space

Product Show

Hot Searches