- Product Details

- {{item.text}}

Quick Details

-

Max. Cutting Thickness:

-

20 mm

-

Material Strength:

-

≤ 450 N/mm2

-

Angle Of Shear:

-

8 Degree

-

Flat Bar Shearing (T * W ):

-

20 *3 30 10 *480 mm

-

Max. Stroke Length:

-

80 mm

-

Depth of Thorat:

-

355 mm

-

Punch Depth:

-

20 mm

-

OEM:

-

Yes

-

Weight:

-

2000 KG

-

Certification:

-

CE ISO

-

Power:

-

7.5 KW

Quick Details

-

Place of Origin:

-

Anhui, China

-

Product name:

-

Hole Punching Machine

-

Punching Pressure:

-

90 T

-

Max. Cutting Thickness:

-

20 mm

-

Material Strength:

-

≤ 450 N/mm2

-

Angle Of Shear:

-

8 Degree

-

Flat Bar Shearing (T * W ):

-

20 *3 30 10 *480 mm

-

Max. Stroke Length:

-

80 mm

-

Depth of Thorat:

-

355 mm

-

Punch Depth:

-

20 mm

-

OEM:

-

Yes

-

Weight:

-

2000 KG

-

Certification:

-

CE ISO

-

Power:

-

7.5 KW

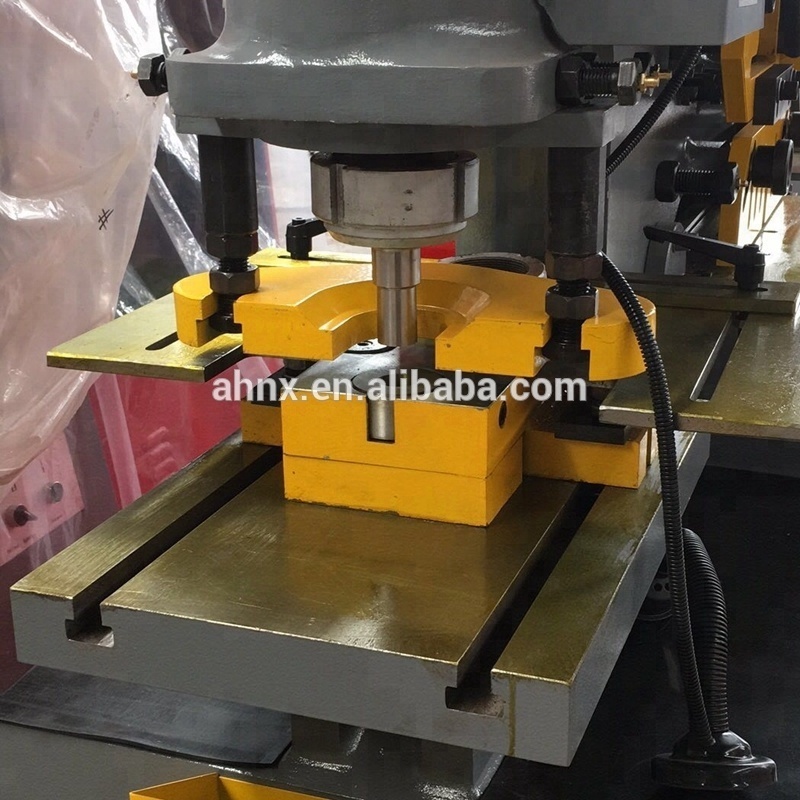

Q35Y Series Hydraulic Ironworker Hole Punching Machine

What Features of our Hole Punching Machine ?

H(Q35Y) series industrial-grade hydraulic iron - worker is a combined punching and shearing machine, featuring multiple functions, including: punch all kinds of holes (round, square, oblong hole), louver punch, angle steel shear, flat steel shear, profile steel shear(channel, I-beam, round/square bar, T-bar shear), notch, V-notch, bending, angle bending . We can design any special tools according to your metal fabricating requirements.

It is widely used in steel structure, high voltage tower, telecommunication tower, large rigid frame bridge, military and air craft and other metal fabricating industries. Standard equipped with quick-change coupling nut & sleeve, squaring arm with scale, electronic back gauge, gauging table with stops, punching base table, safety guards and more.

Optional configuration:

v Automatic Holding System:

The automatic holding system can be chosen to set up in angle steel shearing and plate shearing work position. Additionally, the holders will fix the position of work piece in order to save time and improve working efficiency.

v Temperature cooling system:

When the machine is working, you can read the temperature of oil through the monitoring screen. If the oil temperature goes higher than 55 degree which is the default configuration, the inside cooling system will run automatically to decrease oil temperature in order to protect hydraulic system.

v Dual working system:

At this condition, punching and shearing position can work synchronously, suitable for volume-production.

What Main Components of our Hole Punching Machine ?

v CE certificate electrical parts

v Professional design frame structures(steel frame Q235 = American standard steel A306 GR55)

v Steel welds with high precision strength and rigidity to eliminate vibrations

v Standard with a set of punch and die, four sets of blades

v Timer relay by Japanese OMRON

v All wiring terminal block by Germany WEIDMULLER

v Main Electrical component by French Schneider

v Oil seals by Japanese, NOK more durable

v Hydraulic pump made by Taiwan

v Hydraulic valve made by Beijing Huade

v Motor by China Jiangsu Dazhong

v Hydraulic fuel tanks and iron - worker frame made by our Factory

v Dual independent hydraulic cylinder

v Dual foot switches controlled to work separately

v Easy Adjustable stroke control with ruler

v Indicator on both hydraulic cylinders

v 1m electric back gauge auto stop

v Moveable working light which can be placed at any desired position

v Hydraulic system with overload protection system

v Emergency safety stop switch

v Large punching, notching, shearing table with ruler guide

v Machine is easy to maintain

What Optional Equipment of our Hole Punching Machine ?

v Square, oval, louver punch and die

v Channel shear and I-beam shear

v Conveyor table

v Longer worktable

v Worktable with linear guide

v Φ20, 32, 60mm U type circle

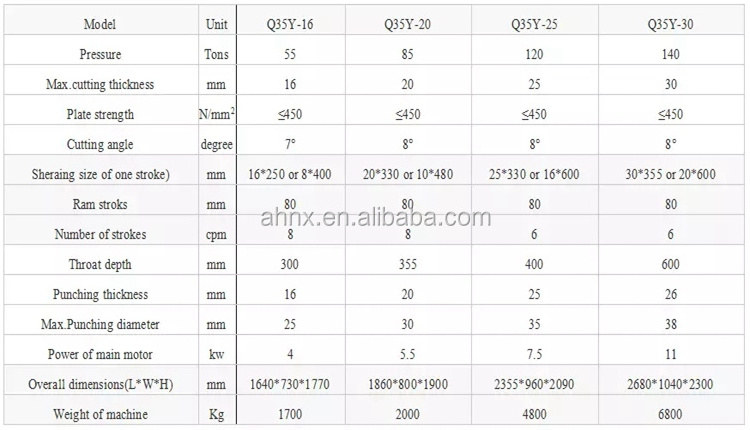

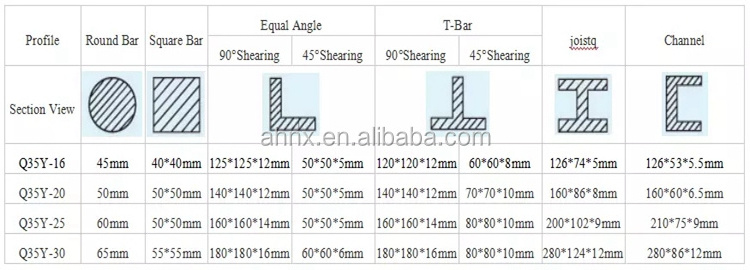

What Technical Parameters of our Hole Punching Machine ?

What Production Process of our Hole Punching Machine ?

More Pictures of our Hole Punching Machine

FAQ :

Contact Us: