- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2230*1000*2240

-

Weight:

-

520 KG

-

Motor:

-

7.5KW, 50HZ, 380V, 3 phase

-

Max. log diameter:

-

38cm

-

Max.log length:

-

55cm

-

Saw motor with bearing:

-

36L/min, 4800rpm

-

Chain saw:

-

18inch(Original STIHL)

-

Cylinder Bore:

-

4 inches

-

Cycle time:

-

8 secondes

-

Wheel:

-

12 inches high speed trailer wheel

-

Knife:

-

4 ways (Optional 6 ways)

-

Color:

-

Customised

Quick Details

-

Use:

-

Cut, split and load firewood

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

RIMA

-

Dimension(L*W*H):

-

2230*1000*2240

-

Weight:

-

520 KG

-

Motor:

-

7.5KW, 50HZ, 380V, 3 phase

-

Max. log diameter:

-

38cm

-

Max.log length:

-

55cm

-

Saw motor with bearing:

-

36L/min, 4800rpm

-

Chain saw:

-

18inch(Original STIHL)

-

Cylinder Bore:

-

4 inches

-

Cycle time:

-

8 secondes

-

Wheel:

-

12 inches high speed trailer wheel

-

Knife:

-

4 ways (Optional 6 ways)

-

Color:

-

Customised

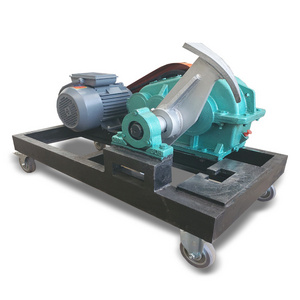

Product Application

The RM7-20E cuts and splits logs up to Ø 38cm in 4 or 6 parts in one work cycle. The cutting length can be adjusted from 23 to 55cm. The hydraulic timber feed transports the timber to the chain saw blade via the conveyor belt. The finished billets are directly transported to loading via conveyor belt.

Main Features

1)Production Rate: up to 8-10m3/h

2) Cycle Time (cut and split): every 8 seconds

3) Maximum Log Diameter: 15 "(38cm)

4) Maximum Log Length: 22"(55cm)

5) Motor: 7.5KW, 50HZ, 380V, 3 phase

Professional log feed ensures continuous log charging.

STIHL chain saw convinces with its cutting power, the high cutting speed and little wear.

The hydraulic log downholder ensures safe fixing of the logs during cutting.

The cut log section is passed on to the splitting punch via the hydraulic ejection rocker and the log chute.

The convey system is a fast and efficient solution for packing up billets.

Motor: 7.5KW, 50HZ, 380V, 3 phase

Longitudinal Conveyor

ptionally, Use the feed belt for the hydraulic transporting of the logs to the STHIL saw blade.

The log support with lifting device

The log support lifts the individual logs off the floor to processing height and gets them ready for use.

Cross Conveyor

The logs are placed down with a forklift truck or timber loading crane and made available for further processing.

Splitting Knife

With the hydraulically adjustable splitting knife, the RIMA produces up to 6 billets in one work cycle.

Conveyor

The conveyor belts transport the finished billets to the respective packaging solution.

In spite of the premium quality of the construction of our machinery, we have to replace wear parts after a certain period of time too. In order to ensure that you get quick and competent help for your device, we recommended that

wear parts

should also be added into your cart.

16" for 7T firewood processor

18" for 12T and 20T firewood processor

16" for 7T firewood processor

18" for 12T and 20T firewood processor

We hire the

best

people, and we give them the

best

tools to complete every step in the fabrication and machining of our products.

Our

CNC-equipped

facility, with milling machines, lathes and plasma arc cutter, helps them to efficiently translate custom drawings into finished products with utmost precision.

By manufacturing our own shafts

, sheaves, hydraulic cylinders, manifolds and valve blocks to order, Mack ensures consistent strength and precision in all our key components.

Quality inspections

are completed and documented at every stage of production, with a final inspection before delivery to ensure complete conformance to the customer's expectations.

Established in 2014, our company has grown from its humble origins into an experienced exporter and highly respected manufacturer of high-quality firewood processors and accessories. Our machines can be outfitted with power plants including 14HP KOHLER and 13.5HP BRIGGS&STRATTON Twin Gas Powered, and also can be customized with PTO tractor-driven or 3 phase electric power.