Adopt ball screw, linear guide

Servo motor drive the back gauge

High positioning accuracy

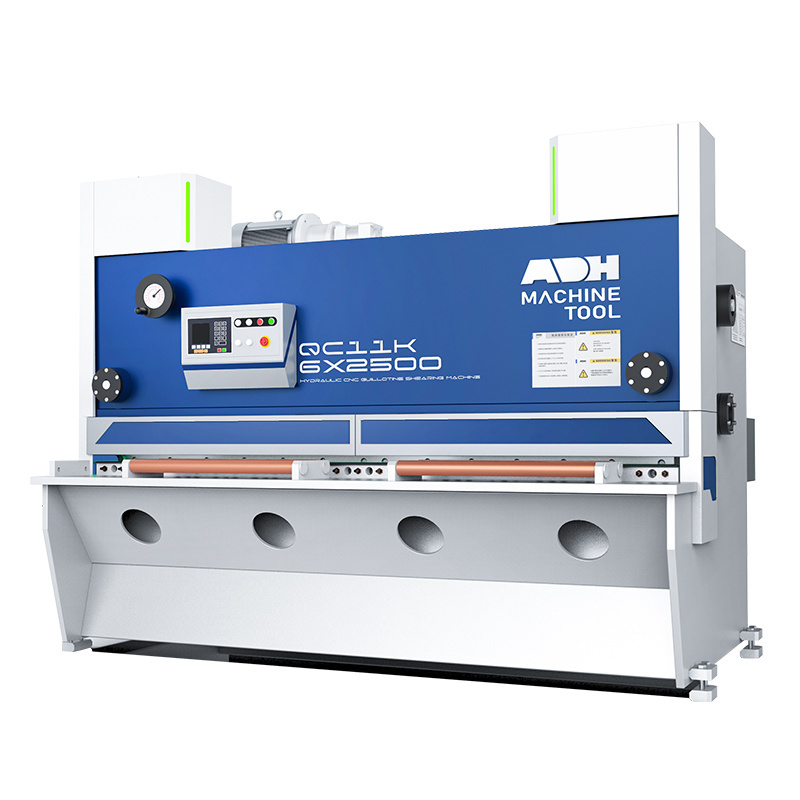

Integrated steel welded structure,eliminate stress by vibration

Advanced hydraulic integrated valve block

Accumulator return smooth and rapid

Manual/automatic adjustment of blade clearance

Adjustable shear angle

Motorized back gauge and position display

Rolling material support ball

- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

3200 mm

-

Backgauge Travel (mm):

-

20 - 800 mm

-

Throat Depth (mm):

-

200 mm

-

Brand Name:

-

ADH

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

7000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

380V 220V Optional

-

Marketing Type:

-

Hot Product

-

Rated Power:

-

11kw

-

Color:

-

Optional

-

Strokes:

-

12-30

-

Cutting thickness:

-

8 mm

-

Cutting Angle:

-

0.5-1.5

-

Cutting material:

-

Metal Stainless Steel Carbon Steel Aluminum

-

Control system:

-

Estun E21 NC Control

-

Main Motor:

-

11 KW

-

Oil Tank Capacity:

-

360 L

-

Backguage Range:

-

20- 800 mm

Quick Details

-

Max. Cutting Width (mm):

-

3200 mm

-

Max. Cutting Thickness (mm):

-

8 mm

-

Shearing Angle:

-

1.5

-

Blade Length (mm):

-

3200 mm

-

Backgauge Travel (mm):

-

20 - 800 mm

-

Throat Depth (mm):

-

200 mm

-

Brand Name:

-

ADH

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

7000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

380V 220V Optional

-

Marketing Type:

-

Hot Product

-

Rated Power:

-

11kw

-

Color:

-

Optional

-

Strokes:

-

12-30

-

Cutting thickness:

-

8 mm

-

Cutting Angle:

-

0.5-1.5

-

Cutting material:

-

Metal Stainless Steel Carbon Steel Aluminum

-

Control system:

-

Estun E21 NC Control

-

Main Motor:

-

11 KW

-

Oil Tank Capacity:

-

360 L

-

Backguage Range:

-

20- 800 mm

Products Description

GUILLOTINE SHEAR

Main component

The shearing machine features a fully welded box bed frame integrated with the workbench, providing exceptional stiffness to handle high torque loads efficiently.

Its vertical linear movement relative to the lower blade minimizes sheet distortion, ensuring precise straightness during the shearing process.

Control System

Upgraded to Delem's DAC360T touch screen version, the CNC system in the machine offers precise control over the back stop, blade angle, and blade gap settings.

Delem, a Netherlands-based brand, provides advanced functionality for efficient and accurate adjustments in the machine's operations.

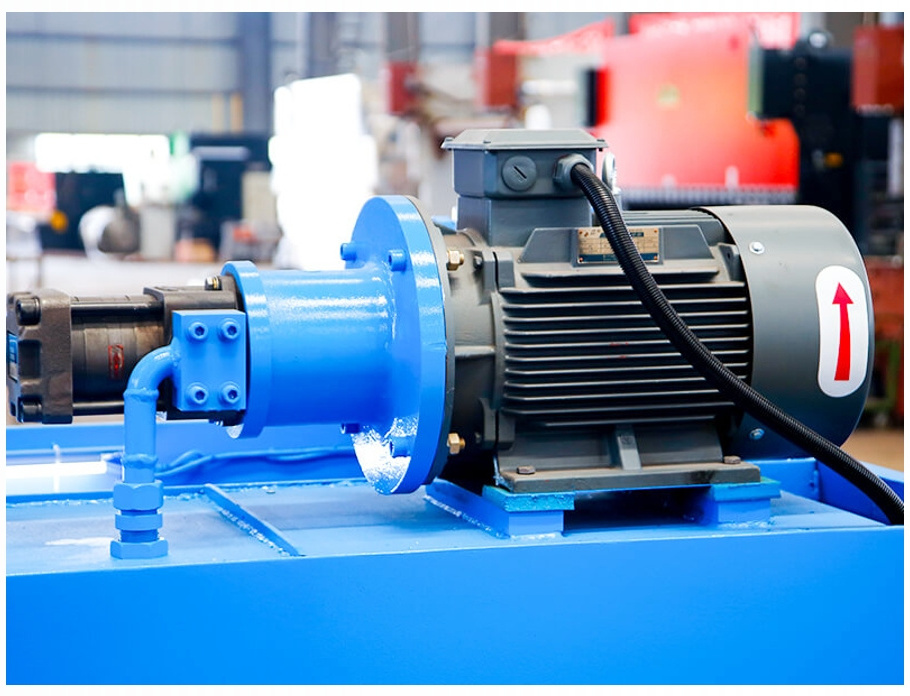

The high-performance main motor options include internationally recognized brands like Siemens and the well-known Chinese brand Wannan.

Voltage customization offers flexibility with choices like 3-phase/220V/60Hz, 3-phase / 380V / 60Hz, and 3-phase / 415V/60Hz, catering to diverse electrical requirements.

The machine features a Rexroth hydraulic valve block, known for its international reputation for quality and reliability.

With oil pressure overload protection, the system minimizes oil leakage and valve jamming, enhancing operational efficiency.

Real-time oil pressure monitoring maintains a consistent oil circuit, promoting stable performance of the equipment.

Feed port design meets international safety standards with adjustable height screws for precise adjustments.

Minimum feeding height matches sheet thickness, and maximum height extends sheet thickness by 20-25mm for versatile use.

Front fence and side guardrail enhance machine safety during operation for added protection.

The machine features a light alignment device for easy marking and shearing, enhancing accuracy in cutting tasks.

Its blade holder offers stepless stroke adjustment, allowing for precise customization to meet varying cutting requirements.

The machine offers a pneumatic rear support device for cutting thin plates, enhancing precision and surface finish quality.

Its rear light curtain protection system guarantees operator safety, meeting international safety standards during operation.

Motorized Cutting Angle Adjustment

Automatic shearing angle adjustment based on plate thickness, reducing manual labor and improving efficiency.

Motorized system eliminates the need for manual adjustments, enhancing precision and consistency.

Streamlined process increases productivity by adapting shearing angle to plate thickness automatically.

The machine features premium electrical components known for their stability and durability, contributing to a prolonged service life.

The rear servo reduction motor delivers high-quality performance with fast positioning speeds, enhancing efficiency in simulation operations.

With its exceptional quality and swift positioning speeds, the rear servo reduction motor excels in providing efficient and reliable operation for simulation tasks.

A

Hydraulic Oil Cooling Device

The machine's hydraulic oil cooling device increases efficiency by maintaining optimal temperature levels, reducing wear and tear on components, and prolonging the lifespan of the machine.

By utilizing advanced cooling technology, this feature enhances productivity by enabling continuous operation, minimizing thermal stress on the system, and ultimately improving the overall reliability and performance of the machine.

Lubrication Device

Optional configuration

Pneumatic Rear Support

The machine provides the convenience of cutting wide sheets with a single key closure feature, enhancing user efficiency and ease of operation.

Control System Options

:

Hydraulic Oil Cooling Device

The machine's operational durability in high-temperature settings allows for continuous use over extended periods without compromising performance or reliability.

Rear Protection Device

Implementation of photoelectric protection enhances personal safety, specifically protecting fingers from harm.

Estun E21s

Estun

E200Ps

DELEM DAC360s

Product Paramenters

|

Model

|

Max. Cutting Thickness

|

Width

|

Oil Tank

|

Strokes

|

Backgauge range

|

Cutting Angle

|

Main Power

|

|

Q11Y/K-6*2500

|

6

|

2500

|

300

|

16-25

|

20-800

|

30`-1°30`

|

7.5

|

|

Q11Y/K-6*3200

|

6

|

3200

|

300

|

14-20

|

20-800

|

30`-1°30`

|

7.5

|

|

Q11Y/K-6*4000

|

6

|

4000

|

340

|

12-17

|

20-800

|

30`-1°30`

|

7.5

|

|

Q11Y/K-6*5000

|

6

|

5000

|

340

|

8-14

|

20-800

|

30`-1°30`

|

15

|

|

Q11Y/K-6*6000

|

6

|

6000

|

340

|

7-12

|

20-800

|

30`-1°30`

|

15

|

|

Q11Y/K-8*2500

|

8

|

2500

|

300

|

13-20

|

20-800

|

30`-1°30`

|

11

|

|

Q11Y/K-8*3200

|

8

|

3200

|

300

|

11-18

|

20-800

|

30`-1°30`

|

11

|

|

Q11Y/K-8*4000

|

8

|

4000

|

340

|

9-16

|

20-800

|

30`-1°30`

|

15

|

|

Q11Y/K-8*5000

|

8

|

5000

|

350

|

8-15

|

20-800

|

30`-1°30`

|

15

|

|

Q11Y/K-8*6000

|

8

|

6000

|

580

|

7-14

|

20-800

|

30`-1°30`

|

18.5

|

|

Q11Y/K-13*2500

|

13

|

2500

|

405

|

10-20

|

20-800

|

30`-2°

|

22

|

|

Q11Y/K-13*3200

|

13

|

3200

|

405

|

9-18

|

20-800

|

30`-2°

|

22

|

|

Q11Y/K-13*4000

|

13

|

4000

|

405

|

8-16

|

20-800

|

30`-2°

|

22

|

|

Q11Y/K-13*5000

|

13

|

5000

|

505

|

7-14

|

20-1000

|

30`-2°

|

22

|

|

Q11Y/K-13*6000

|

13

|

6000

|

1020

|

6-12

|

20-1000

|

30`-2°

|

30

|

|

Q11Y/K-16*2500

|

16

|

2500

|

475

|

9-18

|

20-800

|

30`-2°30`

|

22

|

|

Q11Y/K-16*3200

|

16

|

3200

|

475

|

8-17

|

20-800

|

30`-2°30`

|

22

|

|

Q11Y/K-16*4000

|

16

|

4000

|

595

|

7-15

|

20-800

|

30`-2°30`

|

22

|

|

Q11Y/K-16*6000

|

16

|

6000

|

1020

|

6-11

|

20-1000

|

30`-2°30`

|

37

|

|

Q11Y/K-16*8000

|

16

|

8000

|

2060

|

4-8

|

20-1000

|

30`-2°30`

|

45

|

|

Q11Y/K-20*2500

|

20

|

2500

|

510

|

7-16

|

20-800

|

30`-3°

|

30

|

|

Q11Y/K-20*3200

|

20

|

3200

|

510

|

6-15

|

20-800

|

30`-3°

|

30

|

|

Q11Y/K-20*4000

|

20

|

4000

|

640

|

6-14

|

20-800

|

30`-3°

|

37

|

|

Q11Y/K-20*6000

|

20

|

6000

|

1500

|

5-11

|

20-1000

|

30`-3°

|

30*2

|

|

Q11Y/K-25*2500

|

25

|

2500

|

750

|

5-14

|

20-800

|

30`-3°30`

|

37

|

|

Q11Y/K-25*3200

|

25

|

3200

|

820

|

5-10

|

20-800

|

30`-3°30`

|

37

|

|

Q11Y/K-25*4000

|

25

|

4000

|

1200

|

5-8

|

20-800

|

30`-3°30`

|

45

|

|

Q11Y/K-30*2500

|

30

|

2500

|

780

|

5-12

|

20-1000

|

30`-3°

|

45

|

|

Q11Y/K-30*3200

|

30

|

3200

|

1000

|

4-10

|

20-1000

|

30`-3°30`

|

55

|

|

Q11Y/K-30*4000

|

30

|

4000

|

1400

|

3-7

|

20-1000

|

30`-3°30'

|

55

|

|

Q11Y/K-40*2500

|

40

|

2500

|

1370

|

4-8

|

20-1000

|

30`-4°

|

55

|

|

|

|

|

|

|

|

|

|

About us

EMPLOYEES: 617 SALES & SERVICES OFFICES: 67 R&D TECH: 43

Founded in March 2002, Anhui Donghai Machine Tool Co., Ltd. (Brand: ADH) is a high-tech enterprise specializing in the production of press brake, hydraulic guillotine, fiber laser cutter etc.

ADH is a comprehensive leading enterprise in the machine tool industry in China, which integrates automatic control system design, new product research and development, and equipment manufacturing innovation platform formation.

Our factory is located in Bowang District, Ma'anshan City, Anhui Province, only 30 kilometers away from Nanjing Lukou International Airport and can be reached within 30 minutes by car.

Manufacturing Technique

Our frame is manufactured through large-scale processing equipment, which includes overall processing, heat treatment, shot

blasting, and welding. As a result, our equipment's frame is more stable and durable, while ensuring final processing accuracy.

blasting, and welding. As a result, our equipment's frame is more stable and durable, while ensuring final processing accuracy.

The gantry pentahedron machining center is adopted to complete the whole machine processing at one time, so as to ensure the

machine accuracy and the bending accuracy.

machine accuracy and the bending accuracy.

The body and important welding parts are tempered to eliminate welding stress and ensure the stability of the machine for long-term use。

Shot blasting can remove surface rust and oxide scale and improve paint adhesion, so as to improve the anti rust ability of the

whole machine;

At the same time, it can further eliminate the internal stress of parts and prolong the service life of the machine;

whole machine;

At the same time, it can further eliminate the internal stress of parts and prolong the service life of the machine;

Quality, Delivery

Quality Control

Our machine manufacturing leads the industry in China, setting benchmarks for quality and performance.

Our quality inspection process rigorously follows industry standards, ensuring the reliability of our machines.

Continuous operation of testing machines guarantees compliance with the highest standards before our products are dispatched.

Delivery

Offers customizable packaging options, including wooden cases, for sea transportation to ensure machine integrity upon delivery.

Standard machines are available for delivery within a 20-day timeframe.

The machine employs an advanced fixing method that guarantees stability and eliminates vibration during container transport.

Service

IMPROVE SERVICE QUALITY

Anhui Donghai Machine Tool has a huge global customer source market, has a good basic service network and efficient service capabilities for modern sales, has a core position of customer service in a central city, has efficient information diffusion and demonstration effects, and has become a zoning. Focus on sales layout. Strengthen different forms of customer care, strengthen customer care through related theme services, continue to form a good reputation, and quickly improve brand reputation and customer satisfaction.

IMPROVE SERVICE QUALITY

Donghai Machine Tool makes full use of the advantages of more than 60 offices, combines actual conditions, builds unique service brands, promotes the promotion of new products, strengthens in-termal management, improves service processes, improves technical level and service quality, improves customer experience, and customer satisfaction.

FAST RESPONSE

We require all service points to provide 24-hour fast service support and ensure service resources: personnel, spare parts, tools, etc.

STRENGTHEN TRAINING

In order to improve the overall quality of the service network, we will formulate corresponding training plans and training support for service stations to improve service quality, maintain technical level and customer satisfaction from all aspects.

IMPROVE SERVICE QUALITY

Donghai Machine Tool makes full use of the advantages of more than 60 offices, combines actual conditions, builds unique service brands, promotes the promotion of new products, strengthens in-termal management, improves service processes, improves technical level and service quality, improves customer experience, and customer satisfaction.

FAST RESPONSE

We require all service points to provide 24-hour fast service support and ensure service resources: personnel, spare parts, tools, etc.

STRENGTHEN TRAINING

In order to improve the overall quality of the service network, we will formulate corresponding training plans and training support for service stations to improve service quality, maintain technical level and customer satisfaction from all aspects.

Exhibition

Certifications

Our company adheres to the development philosophy of "technical innovation, scientific management, customer-first'and has continuously achieved high-end technological research and development through strong technological innovationThe standardized scientific management, strong technical control, and customer-centric service model have continuouslywon awards and praise from society and the public.

Our Partners

Hot Searches