- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

30 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FRIEND

-

Voltage:

-

380V 50Hz OR Customised

-

Dimension(L*W*H):

-

20 meters long

-

Power (kW):

-

37

-

Weight:

-

2 KG

-

Name:

-

Extrusion Machine

-

Suitable thickness of profile:

-

3-20mm

-

Raw material:

-

PVC Powder

-

Usage:

-

Profile

-

Material:

-

PVC+additives

-

Color:

-

Customers' Require or standard FRIEND's color

-

Temperature controller:

-

Omron Brand

-

Inverter:

-

ABB Brand

-

Contactor:

-

Schnerder

-

Motor:

-

Siemens Beide or Wannan motor

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

25/1

-

Screw diameter (mm):

-

65 mm

-

Screw Speed (rpm):

-

30 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FRIEND

-

Voltage:

-

380V 50Hz OR Customised

-

Dimension(L*W*H):

-

20 meters long

-

Power (kW):

-

37

-

Weight:

-

2 KG

-

Name:

-

Extrusion Machine

-

Suitable thickness of profile:

-

3-20mm

-

Raw material:

-

PVC Powder

-

Usage:

-

Profile

-

Material:

-

PVC+additives

-

Color:

-

Customers' Require or standard FRIEND's color

-

Temperature controller:

-

Omron Brand

-

Inverter:

-

ABB Brand

-

Contactor:

-

Schnerder

-

Motor:

-

Siemens Beide or Wannan motor

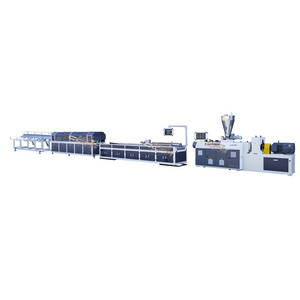

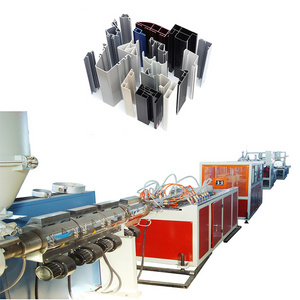

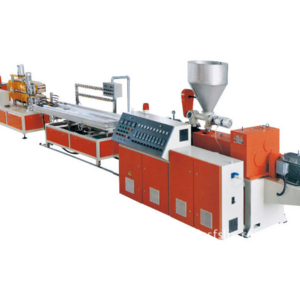

Custom Plastic PVC Profile Extrusion Line

Application

Advantage

Process

|

Machine list

|

|

|

||

|

No.

|

Machine name

|

Pcs

|

||

|

1.

|

SJSZ series twin screw extruder

|

1 set

|

||

|

2.

|

Mold

|

1set or more

|

||

|

3.

|

Vacuum setting table

|

1 set

|

||

|

4.

|

Haul-off machcine

|

1 set

|

||

|

5.

|

Cutting machine

|

1 set

|

||

F unction of each machine

energy, stable and durable.

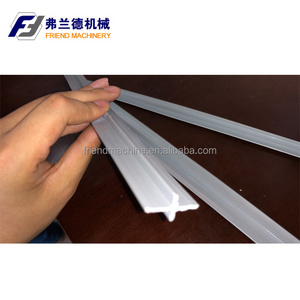

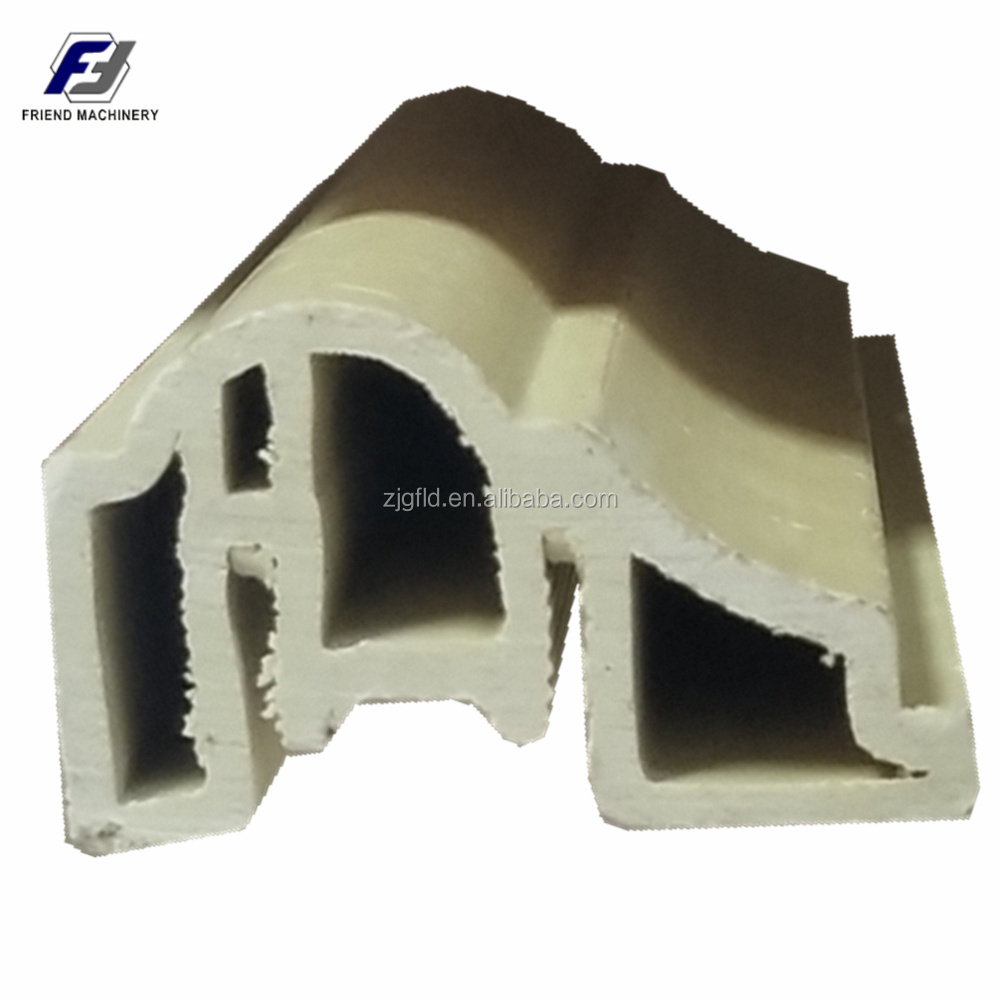

Some of profiles we have made

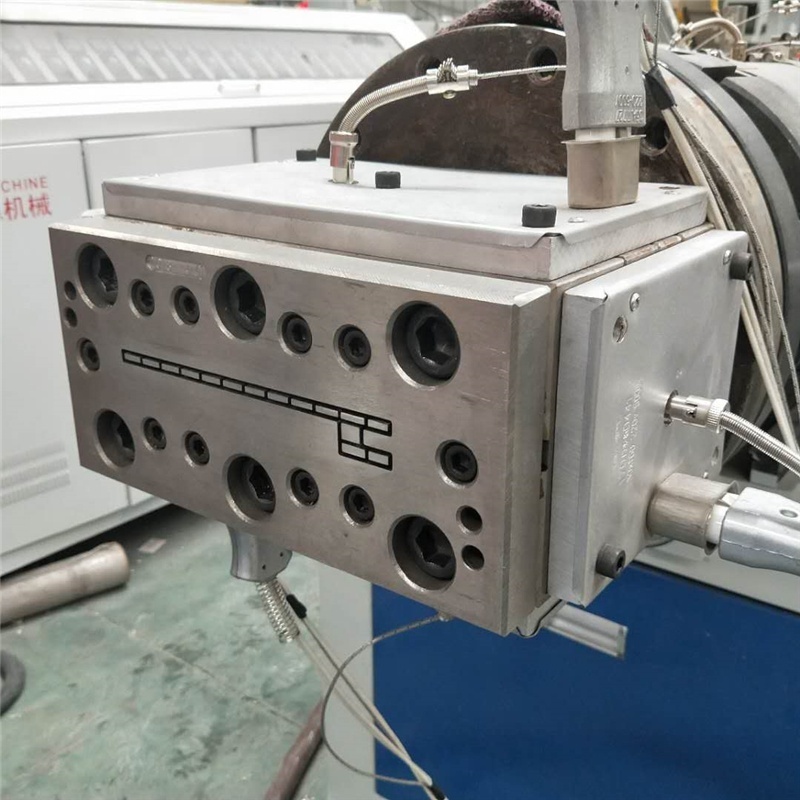

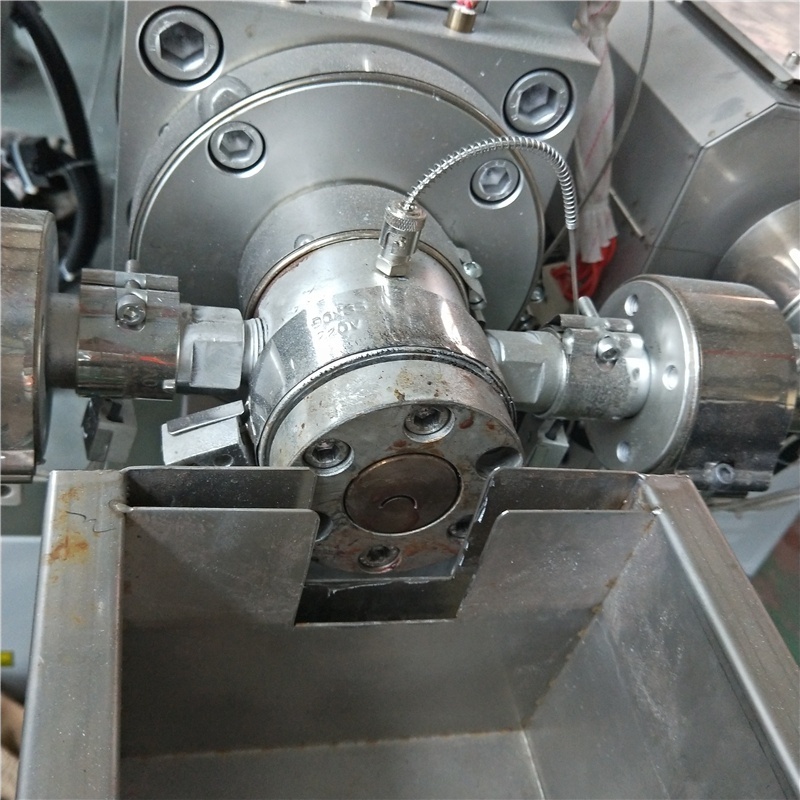

Detailed Pictures

A: both. Which means we can strictly guarantee product quality and lead time.

Q: Do you provide material testing service?

A: Yes, we offer testing service on our machine. An additional testing fee will be charged depends on the testing costs(electricity, labor), however, if you eventually made a purchase with us ,the testing fee will counts as deduction of machine cost.

Q: How am I suppose to trust you the machine I received matches your description?

A:Appearance of Final products may differ from pictures shown, but we can make sure each component and technical parameters remains the same as quoted, we also provide videos of whole traceable production process if necessary.

Q: Do you provide samples for free?

A: Yes, we could offer the sample for free but we do not pay the cost of freight. Also we can provide detailed sample pictures or videos.

1. We not only provide machines but also offer technical support and market evaluate.

2. We will provide all the machines for the complete production line according to customer's requirements.

3. We will provide complete service for factory layout and other information to help customer to build the factory.

4. We will provide good service for machine installation and training, until the customers can run the machines and make stably production.

5. Except for the one year warranty, we will provide after-sales service for all the time.

6. For long-term cooperation, we always provide good quality, good price and offer good service to customers.

ZHANGJIAGANG FRIEND MACHINERY CO.,LTD

Our company covers an area of 7000 square meters and has 60 employees. We are specialized in producing plastic machine and have an annual production capacity of 400 million US dollars. Our company has rich experience in the plastic machinery making industry. Our main products include 3D filament production line, plastic pelletizing machine, waster plastic recycling and washing machine, plastic pipe/board/profile production line, plastic extruder, mixer, crusher and other kinds of auxiliary plastic machine. Besides, we are making great efforts to develop new productions to meet different requirements. Our company has CE, and SGS certificate control the product quality.