- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

9200*1200*1600mm

-

Power (kW):

-

16KW

-

Weight (KG):

-

3500 kg

-

Panel Feed Speed(m/min):

-

14m/min

-

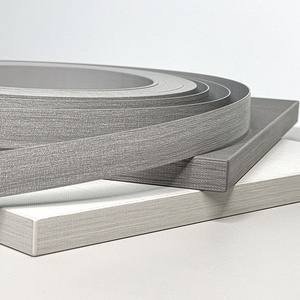

TapeThickness:

-

0.3-3mm

-

Panelthickness:

-

12-55mm

-

Workpiecethickness:

-

10-60mm

-

Heatingpower:

-

2kw

-

Feeding speed:

-

12-20 m/min

-

Pre-heating power:

-

350 w

-

Conveyor belt:

-

1.5 kw

-

Pre-milling power:

-

2.2 kw*2

-

Glue power:

-

0.75kw

-

Working pressure:

-

0.7 Mpa

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ETERNE

-

Voltage:

-

220/380/415 optional

-

Dimension(L*W*H):

-

9200*1200*1600mm

-

Power (kW):

-

16KW

-

Weight (KG):

-

3500 kg

-

Panel Feed Speed(m/min):

-

14m/min

-

TapeThickness:

-

0.3-3mm

-

Panelthickness:

-

12-55mm

-

Workpiecethickness:

-

10-60mm

-

Heatingpower:

-

2kw

-

Feeding speed:

-

12-20 m/min

-

Pre-heating power:

-

350 w

-

Conveyor belt:

-

1.5 kw

-

Pre-milling power:

-

2.2 kw*2

-

Glue power:

-

0.75kw

-

Working pressure:

-

0.7 Mpa

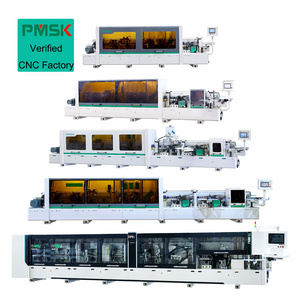

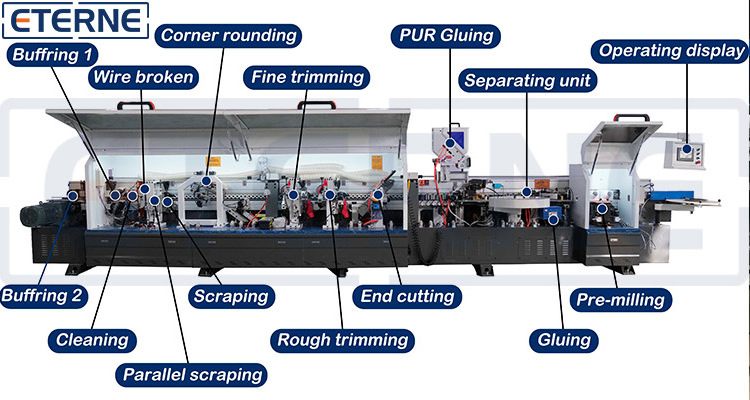

ET-668JP edge banding machine

is a heavy duty automatic edge banding machine with multiple functions. It can be used to process various boards such as MDF, ecological board, multi-layer board, particle board, straight solid wood board, aluminum honeycomb board. It is suitable for panel furniture, custom furniture, cabinets and wardrobes, office furniture, solid wood furniture, tables, chairs, doors and windows, wood products, decoration and decoration industries, etc.

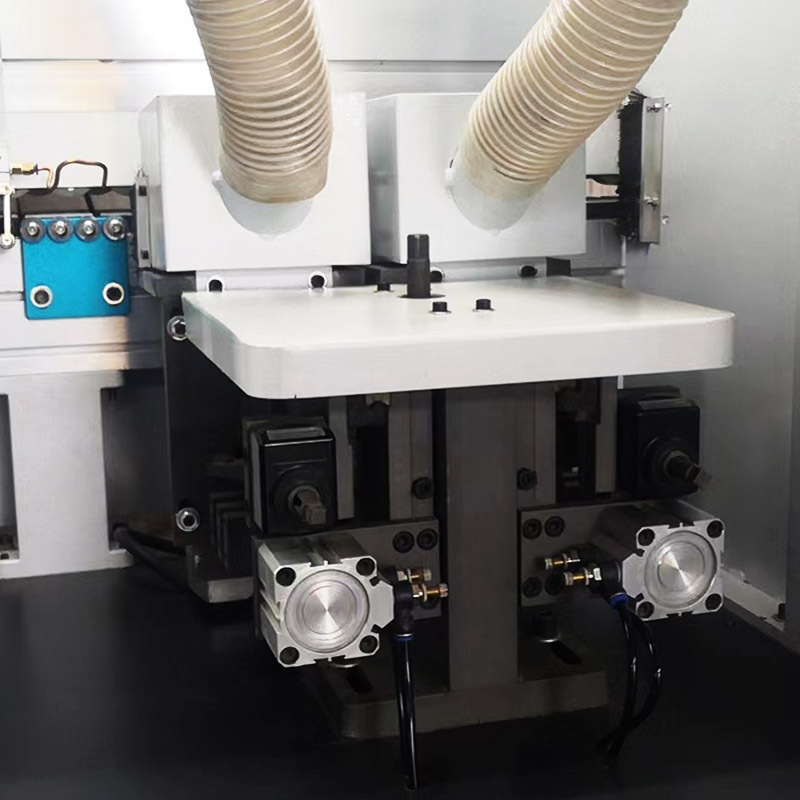

Specific functions include gluing pot (pre-melting), gluing pot, preheating, pre-milling, gluing, 6-round welt, pressing, tape cutting, front and rear alignment, rough trimming, fine trimming, profiling tracking, edge scraping , Polishing, speed regulation, meter recording, air blowing, electric lift, pneumatic knife adjustment and so on.

|

Model

|

ET-668JP

|

|

Edge belt thickness

|

0.4-3mm

|

|

Edge belt width

|

12-55mm

|

|

Feeding speed

|

16m/min

|

|

Panel Length

|

Min.120 mm

|

|

Panel Width

|

Min.60 mm

|

|

Transport Motor

|

2.2 kw

|

|

Panel Preheating power

|

0.3 kW

|

|

Glue Melting Power

|

1.5 kW

|

|

Gluing Motor

|

0.55 kw

|

|

Pre-Milling Motor Power

|

1.8 kw*2

|

|

End-trimming Motor Power

|

0.37w*2

|

|

Fine-trimming Motor Power

|

0.75 kw*2

|

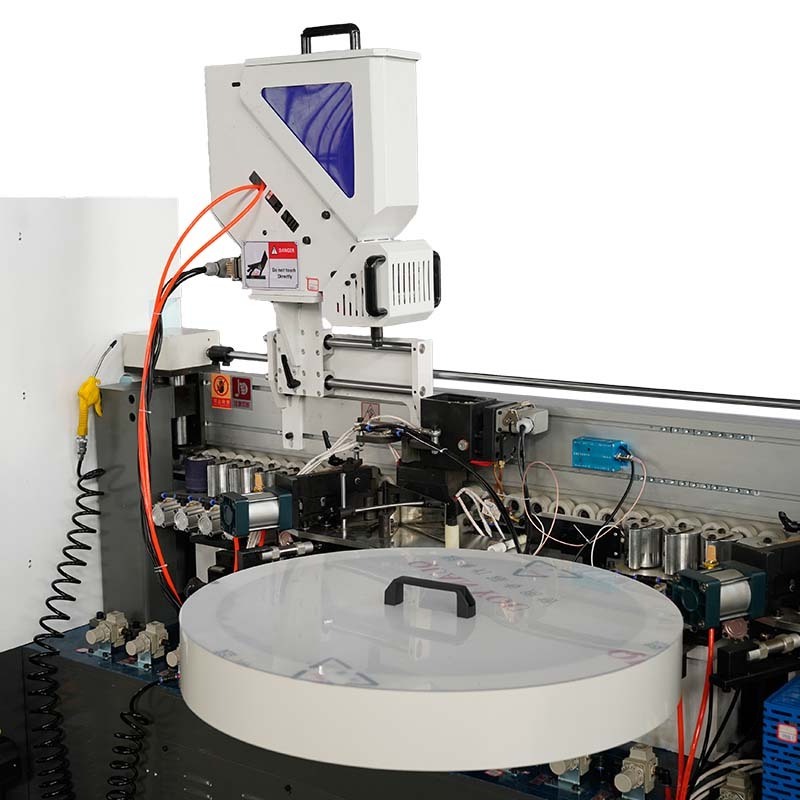

What are the advantages of

PUR glue edge banding machine ?

1.

Save time.

The glue pot is equipped with a quick-dissolve device that quickly dissolves and releases glue within five minutes. Ordinary need to warm up for 30 minutes.

2. The glue pot edge sealing machine dispenses glue quantitatively, which can ensure that the glue line of the sealing board is very small. Moreover, in the glue pot, the glue is left from top to bottom and will

not be heated repeatedly or oxidize and turn yellow

.

3.

No cleaning required

. The glue pot is equipped with a glue storage bin. You can melt as many as you want. Unlike the glue pot, the glue will not be heated repeatedly, causing the glue to turn yellow or black, making the sealing board imperfect.

4. Pur glue and EVA glue can be used interchangeably, which is

suitable for panel furniture processing factories that require frequent replacement of glue

.

1.Multi-language operation screen

We support multi-language operation screen, contact us to see more pictures

2.

The diamond pre-milling cutter mills off the excess burrs on the edge of the board, so that the edge of the board fits better with the edge banding.

3.Two sets of six-wheel pressing devices make the edge banding stick to the board more closely, and the glue feeding device controlled by the air cylinder makes the glue quantity more stable

4.PUR moisture reactive hot sol will react with the moisture in the air after heating, absorb the moisture in the air for curing, and will not melt when heated. This unit saves glue and is resistant to heat and cold, water vapor, chemicals and solvents. The sheet after edge sealing can remain stable at -40°-150°!

5.

Front and rear flush and rough trimming, the finishing function makes the edge more beautiful, the adjustment device with digital meter is very simple and easy to learn.

6.

The Corner rounding function trims the 4 corners into small rounded edges to make the edge banding more smooth

.

The edge scraping function of the alloy R knife smoothes the fine lines of the edge banding.

7.

Two sets of scraping unit for a perfect finishing of the applied edge. Buffing unit is equipped with cotton polishing wheels to make smooth surface by end-polishing.

*

Please contact us for other models

|

Model

|

ET-60

|

ET-360JY

|

ET-360B

|

ET-360YC

|

ET-360YCC

|

ET-468

|

ET-668JP

|

||||||

|

Motor power

|

5.1KW

|

6KW

|

8KW

|

12.5KW

|

22KW

|

14KW

|

16KW

|

||||||

|

Panel width

|

≥60mm

|

|

|

|

|

|

|

||||||

|

Panel thickness

|

10~60mm

|

|

|

|

|

|

|

||||||

|

Edge band thickness

|

0.4~3.0mm

|

|

|

|

|

|

|

||||||

|

Edge band width

|

12~65mm

|

|

|

|

|

|

|

||||||

|

Feed speed

|

0~13m/min

|

|

|

|

|

|

|

||||||

|

Working pressure

|

0.7 Mpa

|

|

|

|

|

|

|

||||||

|

Size(LxWxH)mm

|

2370*680*1460

|

2700*800*1500

|

4080*930*1600

|

5300*1200*1500

|

5700*930*1600

|

6100*1200*1600

|

9200*1200*1600

|

||||||

|

ET-60

|

gluing,trimming,scrapping and buffing,also with manual end cutting

|

|

|

|

|

|

|

||||||

|

ET-360JY

|

gluing,end cutting,fine trimming,scrapping and buffing

|

|

|

|

|

|

|

||||||

|

ET-360B

|

gluing,end cutting,rough trimming,fine trimming,scrapping and buffing

|

|

|

|

|

|

|

||||||

|

ET-360YC

|

pre-milling,gluing,end cutting,rough trimming,fine trimming,scrapping,and buffing

|

|

|

|

|

|

|

||||||

|

ET-360YCC

|

pre-milling,gluing,end cutting,rough trimming,fine trimming,scrapping vertical grooving and buffing

|

|

|

|

|

|

|

||||||

|

ET-468

|

pre-milling,gluing,end cutting,rough trimming,fine trimming,corner rounding,scrapping, and buffing

|

|

|

|

|

|

|

||||||

|

ET-668JP

|

pre-milling,gluing,PUR gluing,end cutting,rough trimming,fine trimming,corner rounding,scrapping, and buffing

|

|

|

|

|

|

|

||||||

1.Chain block quality comparison

2.Inductive switch comparison

3.Chain comparison

Shandong Eterne Machinery Co.,Ltd. is a manufacturer based on woodworking machinery and equipment with high-tech products as direction.

Our main products are automatic edge banding machine, woodworking engraving machine, metal engraving machine, drill row and so on.

The head company“Wanfa Machinery” has more than 30 years of mechanical production experience, it covers 16,000 square meters, has a complete testing and experimental equipment, the application of leading software design and development products, has an excellent research and development environment. The research and development capabilities of new products have always been in the leading position. The products have always maintained the market position of high technical grade, good quality performance and reasonable cost performance. ET machienry had been exported to many countries of the world such as America, Russia, Indonesia, Uzbekistan, Algeria, Mongolia etc more than 20 countries.

Eterne people make full use of technology and brand advantages, established a developed sales network throughout China, at the same time we established a good after-sales service network, can provide customers with quality technical advice and installation and maintenance services.

Q1: Are you a manufacturer or trading company?

A: We are a manufacturer since 2003. We are dedicated to woodworking machinery manufacturing.

Q2: Where is the nearest airport and port from your factory?

A: The nearest airport and port is Qingdao/Jinan international airport.

Q3: How can I get an accurate price?

Kindly send us the picture of furniture you want to produceand and the working size.

Or detailed machine functions you need, electricity voltage, Hz.

Q4: How is your after sales service?

Our sales are online for 24-hours. We can also supply overseas install service. Also we have more than 10 countries warehouse and department.

Q5: How long is the delivery time?

Generally 7 ~ 15 days.

Q6: Can I get a machine according to my own requirements?

Sure.We accept OEM and ODM

Q7: If my machine is broken. Can you repair it for me?

Yes. Our machine is with top quality, if any problem, We have free traning and conduction online. If there is big trouble within

warranty time, we will send you new parts and repair.

Q8: How is the quality of your machine?

Our machine adopts heavy machine body and famous parts such as SKF bearing, Hiwin guide rail, Delta Screen and system, top quality motor etc, well commissioning etc to make sure the whole machine quality is no problem, we have many reputation feedback from Clients.

Q9: What's your MOQ and delivery?

1 set by LCL. 3~9 sets by container

A: We are a manufacturer since 2003. We are dedicated to woodworking machinery manufacturing.

Q2: Where is the nearest airport and port from your factory?

A: The nearest airport and port is Qingdao/Jinan international airport.

Q3: How can I get an accurate price?

Kindly send us the picture of furniture you want to produceand and the working size.

Or detailed machine functions you need, electricity voltage, Hz.

Q4: How is your after sales service?

Our sales are online for 24-hours. We can also supply overseas install service. Also we have more than 10 countries warehouse and department.

Q5: How long is the delivery time?

Generally 7 ~ 15 days.

Q6: Can I get a machine according to my own requirements?

Sure.We accept OEM and ODM

Q7: If my machine is broken. Can you repair it for me?

Yes. Our machine is with top quality, if any problem, We have free traning and conduction online. If there is big trouble within

warranty time, we will send you new parts and repair.

Q8: How is the quality of your machine?

Our machine adopts heavy machine body and famous parts such as SKF bearing, Hiwin guide rail, Delta Screen and system, top quality motor etc, well commissioning etc to make sure the whole machine quality is no problem, we have many reputation feedback from Clients.

Q9: What's your MOQ and delivery?

1 set by LCL. 3~9 sets by container

Hot Searches