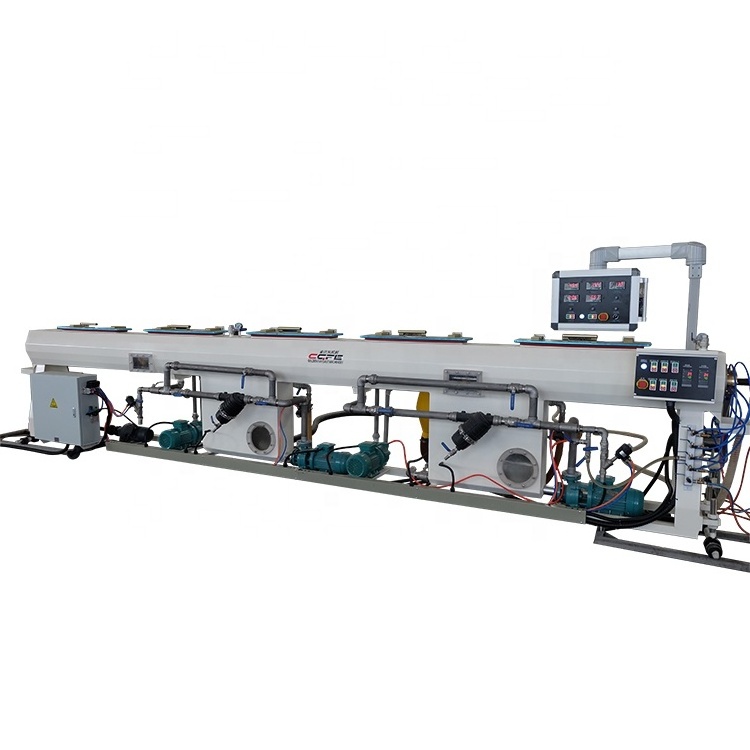

The vacuum calibration tank is advanced in design, it has the advantages of high output, good plasticizing,low energy-consumption and environmental-friendly.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CGFE

-

Voltage:

-

380 V/50HZ

-

Power (kW):

-

55

-

Weight:

-

2 KG

-

Capacity:

-

300-400kg/h

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Video technical support

-

Raw material:

-

pvc

-

Processing Type:

-

Extrusion Process

-

Final product:

-

pvc pipes

-

Inverter:

-

ABB Brand

-

Contactor:

-

Siemens Schneider

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

80/156

-

Screw Speed (rpm):

-

34.9 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CGFE

-

Voltage:

-

380 V/50HZ

-

Power (kW):

-

55

-

Weight:

-

2 KG

-

Capacity:

-

300-400kg/h

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Video technical support

-

Raw material:

-

pvc

-

Processing Type:

-

Extrusion Process

-

Final product:

-

pvc pipes

-

Inverter:

-

ABB Brand

-

Contactor:

-

Siemens Schneider

Products Description

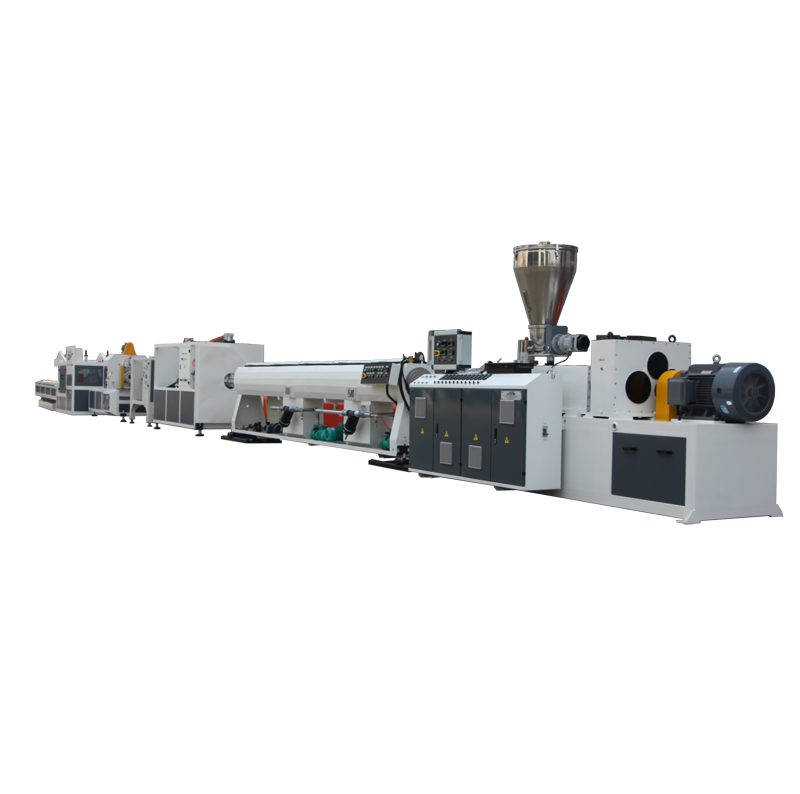

PVC Pipe Production Line

Main Components

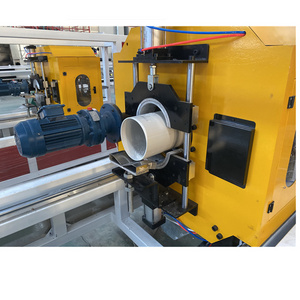

The haul-off machine has different claw number, we have two claws. three claws and so on, it depends on the diameter of the pipes.

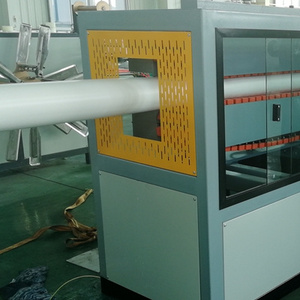

The cutting machine has different types, such as planetary cutter, knife-lifting cutter and no-dust cutter, etc. This unit is reliable and has high production efficiency.

The pipe belling machine is for making different sockets. It is suitable for making U socket, R socket and Z socket. It is fully automatic and equipped with SIEMENS PLC control system.

Processing Flow

raw material mixing → extruder → vacuum calibration tank → cooling tank→ haul-off machine → cutting machine → belling machine

→packaing

Applications

●agricultural irrigation pipe

●constructional plastic pipes

●cable laying

Advantages

●simple operation

●high quality standard

●h

ighly automatic and mechanized, energy saving and environmental-friendly

Electrical Elements

ABB inverter

Screw and barrel

Gearbox

CHINT breaker

FUJI temperature controller

SIEMENS motor

barrel heaters

cooling fans

electrics

Technical Parameter

|

Machine Model

|

SJSZ51

|

SJSZ55

|

SJSZ65

|

SJSZ80

|

SJSZ92

|

SJSZ115

|

|

Pipe Diameter(mm)

|

51/105

|

55/120

|

65/132

|

80/156

|

92/188

|

115/225

|

|

Max output(kg/h)

|

50-120

|

60-150

|

80-250

|

100-400

|

200-800

|

600-1200

|

|

Main power(kw)

|

15

|

22

|

37

|

55/75

|

110

|

110

|

|

Screw rotation speed(r/min)

|

1-32

|

1-40

|

1-34.7

|

1-36.9

|

1-32.9

|

5-32

|

|

Effective Length of Screw(mm)

|

1050

|

1230

|

1440

|

1800

|

2500

|

4100

|

Technology Cooperation

Hot Searches