- Product Details

- {{item.text}}

Quick Details

-

Power:

-

5-10KW

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

400 KG

-

Warranty of core components:

-

1 year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

brewing tank 100lmicro brewing equipment used distillery equipment

-

Material:

-

Stainless Steel 304/316

-

Thickness:

-

Inner 3mm External 2mm

-

Capacity:

-

100L

-

Heating method:

-

Steam ,Electric,Gas

-

Application:

-

Beer Brewing Plant

-

Brewhouse:

-

2/3/4 Vessels

-

Fermentation:

-

60/75 cone

-

Control system:

-

Touch Screen

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

NDL Craft

-

Voltage:

-

208V 3PH 60HZ / 380V 3PH 50HZ

-

Power:

-

5-10KW

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

400 KG

-

Warranty of core components:

-

1 year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

brewing tank 100lmicro brewing equipment used distillery equipment

-

Material:

-

Stainless Steel 304/316

-

Thickness:

-

Inner 3mm External 2mm

-

Capacity:

-

100L

-

Heating method:

-

Steam ,Electric,Gas

-

Application:

-

Beer Brewing Plant

-

Brewhouse:

-

2/3/4 Vessels

-

Fermentation:

-

60/75 cone

-

Control system:

-

Touch Screen

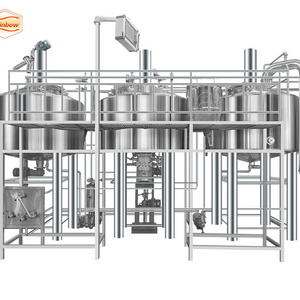

100l beer brewing tank microbrewery equipment

100L brewhouse can be in various combinations:

1. Two vessels: Mash/lauter tank, Kettle/whirlpool tank;

2. Three vessels: Lauter tank+whirlpool, Kettle; Or Mash tun, Lauter tank, Kettle/whirlpool tank;

3. Four vessels: Mash tun, lauter tank, kettle, whirlpool tank;

Here we introduce the 100L brewhouse bases on two vessels

100L brewhouse has three kinds of heating ways:

1. Electric heating

2. Steam heating

3. Direct fire heating

Here we introduce the heating way based on electric heating.

100L two vessels:

100L three vessels:

100L Conical Fermenter:

Send Inquiry>>

|

Items |

Equipment |

Specification |

Quantity |

|

Malt miller |

Malt miller |

80kg/h |

1 |

|

Mash system |

Mash tun&lautering |

100L |

1 |

|

Brew kettle&whirlpool |

100L |

1 |

|

|

Hot liquid tank |

100L |

1 |

|

|

Plate heat exchanger |

2m 2 |

1 |

|

|

Wort oxygenator |

|

1 |

|

|

Pump |

3m ³ /h |

2 |

|

|

Working platform |

|

1 |

|

|

Fermentation system |

Fermenter |

100L |

6 |

|

Yeast adding tank |

2L |

1 |

|

|

Cooling system |

Glycol water tank |

300L |

1 |

|

Cooling compressor |

3HP |

2 |

|

|

Pump |

3m ³ /h |

1 |

|

|

CIP washing system |

Alkali tank |

50L |

1 |

|

Sterilization tank |

50L |

1 |

|

|

Pump |

3m ³ /h |

1 |

|

|

Control system |

Siemens, PLC control, or DCS Semi-automatic control |

|

1 |

|

Spare parts |

All spare parts |

||

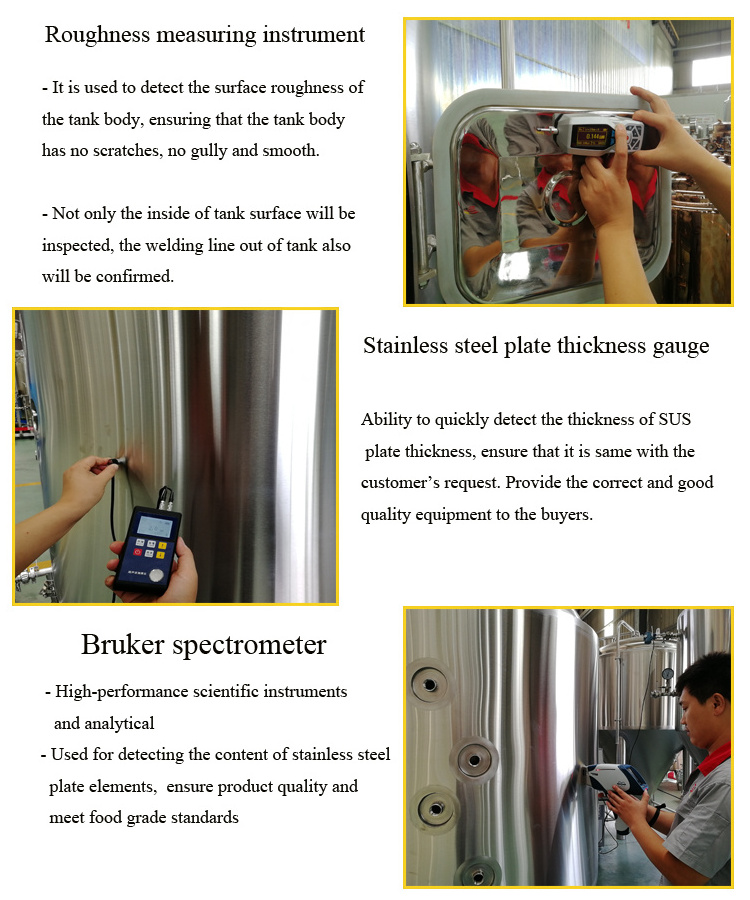

Quality control for the 100L equipment: