Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CNC machine service

-

Brand Name:

-

Customized

-

Product name:

-

Cnc Machining Parts Custom Milling Turning

-

Service:

-

Customized OEM CNC Machining

-

Equipment:

-

3/4/5 Axis Center Machining

-

Materials Avaliable:

-

Aluminum Stainless Plastic Metals Copper

-

Tolerance:

-

0.01mm

-

Surface treatment:

-

Customer's Request

-

Process:

-

Cnc Machining + Surface Treatment

-

Keyword:

-

CNC Macining Parts

-

Application:

-

Industrial Equipment

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, plastic

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

CNC machine service

-

Brand Name:

-

Customized

-

Product name:

-

Cnc Machining Parts Custom Milling Turning

-

Service:

-

Customized OEM CNC Machining

-

Equipment:

-

3/4/5 Axis Center Machining

-

Materials Avaliable:

-

Aluminum Stainless Plastic Metals Copper

-

Tolerance:

-

0.01mm

-

Surface treatment:

-

Customer's Request

-

Process:

-

Cnc Machining + Surface Treatment

-

Keyword:

-

CNC Macining Parts

-

Application:

-

Industrial Equipment

Products Description

Our Service

CNC Machining

CNC Milling

CNC Turning

Laser Cutting

CNC Grinding

Surface Finishing

Our Advantage

Our Advantage:

1.W e are a factory,competitive price for reference and satisfactory services.

2.Import product equipment from Japan/Germany: Mazak/ Okamoto etc

3.OEM & ODM service

4. 10+ years rich experience service for you

5. ISO9001-2015, SGS, ROHS, CE etc Certification

1.W e are a factory,competitive price for reference and satisfactory services.

2.Import product equipment from Japan/Germany: Mazak/ Okamoto etc

3.OEM & ODM service

4. 10+ years rich experience service for you

5. ISO9001-2015, SGS, ROHS, CE etc Certification

6.Confindetial agreetment can be signed to avoid disclosure

7 Germany/Japan import testing equipment as ZEISS THREE-D etc

8.

Experienced staffs answer all your questions in fluent English

9.Samples 3-7days, Larger order always 15-25days

10.

7 days 24 hours online service

What material we can do?

|

Aluminum

|

AL6061, AL6063,AL6068,AL7075,

AL5052,A380

|

|

Stainless Steel

|

SUS303, SUS304, 304L,316,316L

410,420,430

|

|

Brass

|

C11000,C12000,C20000,C26000

C28000,C36000

|

|

Titanium

|

TC1,TC2,TC3,TC4

|

|

Plastic

|

ABS,PC,PE,POM,Nylon,Delrin,Teflon

|

|

Inconel

|

Inconel 718 , Pure nickel N6

|

|

|

17-4PH Steel Cond H1150,9310 alloy steel,Non-magnetic steel HPM75,Nickel-plated carbon steel,pure titanium

|

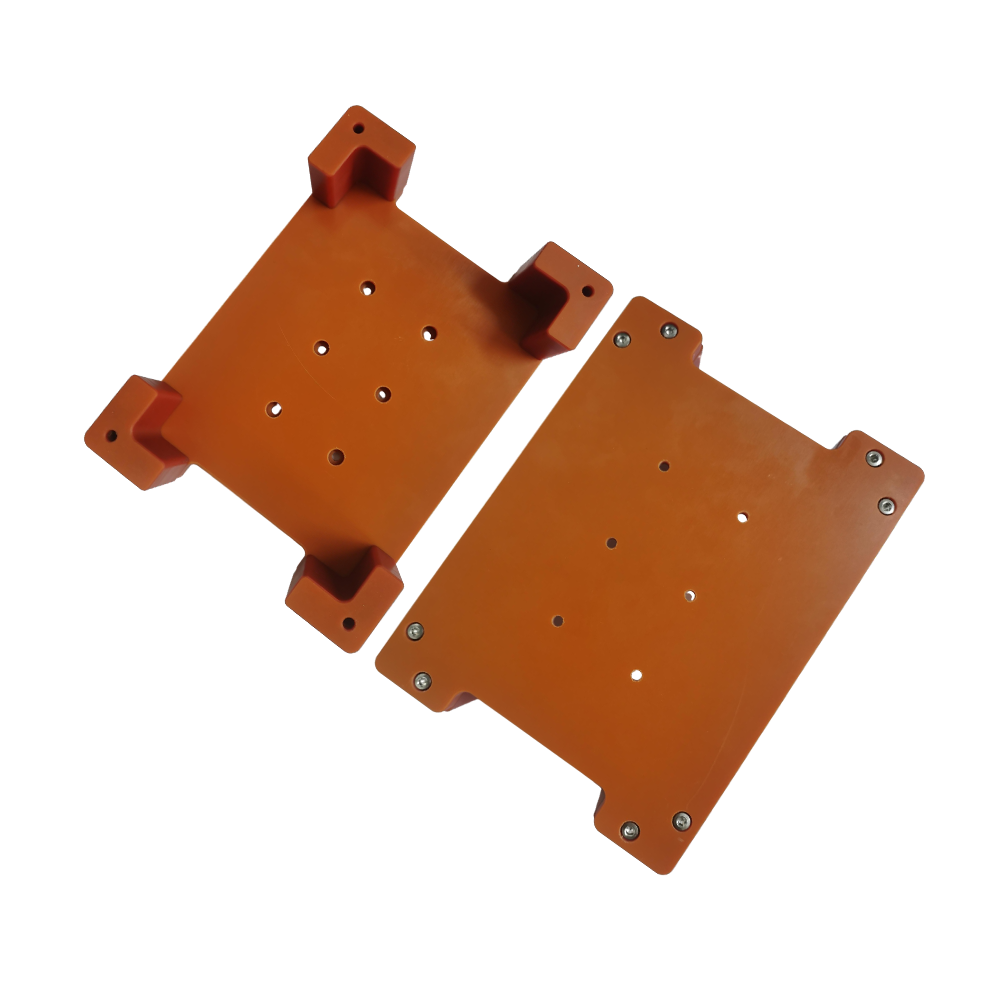

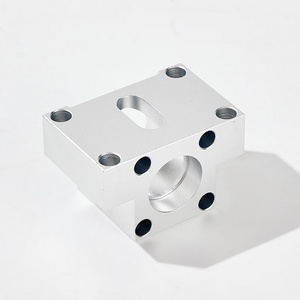

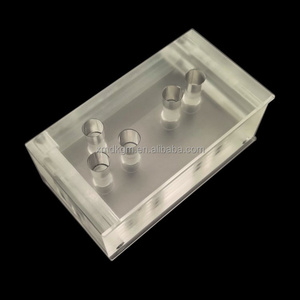

Products show

Manufacturing Technique

The five axis CNC machining center is a CNC machine toolthat integrates milling, precision millingprecision boring,drilling, and reamingFrequently processed high-precision parts such as fuselage components and spiral grooves in theaerospace field, as well as medical devices, inclined slots and holes, and complex curved hardwarepartsProcessing materials: high hardness materials such as stainless steel and steel parts

Accuracy up to +/-0.005mm, high positioning accuracy, stable and reliable quality ofmachining partsWorkpiece one-time clamping, reduce the positioning error caused by multiple installation.reliable equipment itself accuracy to ensure the quality of processingMain processing shaft, gear, drive shaft and other parts after hardening heat treatment

CNC lathe machining

lt can effectively reduce the processing time of parts and improve production efficiencyMachining accuracy up to 0.005-0.01mm, positioning accuracy is relatively high.The processing quality is stable and reliable, under the same processing conditions, using thesame tool and processing program, the tool path is exactly the same, the consistency of theparts is good, the quality is stable

Reduce processing time, improve processing accuracy, and can process all five

surfaces in one clamping operation

Reduce clamping times, improve machining accuracy, accuracy range+/-0.005MM

Processing materials such as copper, iron, aluminum alloy, stainless steel, Teflon, etc

Quality Control

Quality Control Standards

1. Comprehensive written procedures and policies

2. Details records of incoming raw material

3. Analysis of root cause of non-conformances

4. Fully equipped inspection department

5. Consistent calibration and labeling of inspection tools

During the production process, we will implement stricter standards than the ISO tolerance DIN ISO 2768-1 for the necessary parts, as well as the CNC machining standard tolerances of our machines

|

Nominal linear range tolerance/mm

|

Linear dimensions DIN ISO 2768-F

|

Our metal parts

|

Our plastic parts

|

|

0.5 up to 3

|

±0.05

|

±0.02

|

±0.05

|

|

Over 3 up to 6

|

±0.05

|

±0.03

|

±0.05

|

|

cover 6 up to 30

|

±0.1

|

±0.05

|

±0.1

|

|

over 30up to 120

|

±0.15

|

±0.05

|

±0.15

|

|

over 120 up to 400

|

±0.2

|

±0.1

|

±0.2

|

|

Nominal angle range tolerance/mm

|

Linear dimensions DIN ISO 2768-F

|

Our metal parts

|

Our plastic parts

|

|

≤10

|

±1°

|

±1°

|

±1°

|

|

10-50

|

±0°30°

|

±0°30°

|

±0°30°

|

|

50-120

|

±0°20°

|

±0°20°

|

±0°20°

|

|

120-400

|

±0°10°

|

±0°10°

|

±0°10°

|

Hot Searches