■ The brick moulds are made of 16# manganese steel. Besides the good raw material, precise line cutting technology and 900℃ carburizing heat treatment technology are all adopted in the process of the brick mould production. So the brick moulds have

better performance and longer service time.

■ The mould can be customized according to your need.

- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*150*200 mm, 400*200*200 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

donyue

-

Voltage:

-

According to customer requirements

-

Dimension(L*W*H):

-

1850mmX1880mmX2240mm

-

Weight (KG):

-

1560 kg

-

Raw material:

-

Sand

-

Block Type:

-

Hollow

-

Keywords:

-

Brick Making Mahcine

-

Model:

-

QT4-24

-

Color:

-

Customer's Requirement

-

Advantage:

-

Operating Easily

-

Pallet size:

-

850*550*25mm

-

Weight:

-

1.56T

-

Molding cycle:

-

20-24s

-

Vibration force:

-

35.5 KN

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 3400 pcs/8hours, 3000 pcs/8hours, 3200 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*150*200 mm, 400*200*200 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

donyue

-

Voltage:

-

According to customer requirements

-

Dimension(L*W*H):

-

1850mmX1880mmX2240mm

-

Weight (KG):

-

1560 kg

-

Raw material:

-

Sand

-

Block Type:

-

Hollow

-

Keywords:

-

Brick Making Mahcine

-

Model:

-

QT4-24

-

Color:

-

Customer's Requirement

-

Advantage:

-

Operating Easily

-

Pallet size:

-

850*550*25mm

-

Weight:

-

1.56T

-

Molding cycle:

-

20-24s

-

Vibration force:

-

35.5 KN

Product Description

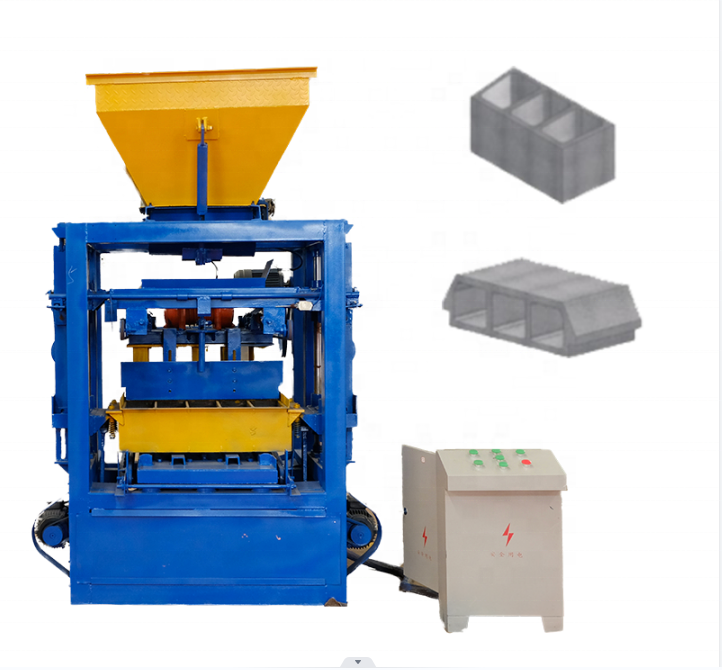

The main advantage of QTF4-24 semi auto block making machine .

1.QT4-24 block machine is one of our newly designed block making machine. With less power.

2.It adopts full automatic spiral material laying method, so the material in the mould is well-distributed. With simple operation and high productivity, when producing hollow blocks, it has an advantage over the large hydraulic block machines.

3.It uses Mode 350 speed reducer to raise and lower the mold, so it greatly increases the usage life of the speed reducer.

4.It combines pressure and super vibration. The lower vibration adopts two 3 KW vibrators and the upper vibration adopts two 1.5 KW vibrators, so the blocks made by this machine has high strength and accurate size.Its performance and product quality are comparable to the large equipment.

|

Main Technical Parameter

|

|

|

|

|

||||

|

Host machine size

|

1850x1880x2240MM

|

|

Molding Cycle

|

20-24S

|

||||

|

Vibration Force

|

33.5KN

|

|

Host Machine Power

|

13.45KW

|

||||

|

Host machine weight

|

1.56T

|

|

Pallet Size

|

850x550x20MM

|

||||

|

Production Capacity

|

|

|

|

|

||||

|

Name

|

Block size

|

pcs per mould

|

pcs per hour

|

pcs per 8 hour

|

||||

|

hollow block mould

|

400x200x200MM

|

4

|

360-450

|

2880-3600

|

||||

|

solid brick mould

|

240x115x53MM

|

24

|

3600-4200

|

28800-33600

|

||||

|

paver brick mould

|

200x100x60MM

|

12

|

1080

|

8640

|

||||

|

paver brick mould

|

200x163x60MM

|

10

|

900

|

7200

|

||||

Details Images

Block mould .

Vibration System

.

1.Adopt vibration moulding technology and equipped with three vibrators to assure better quality, larger density and higherstrength of the blocks.

2.Low power can achieve super super moulding effect.

2.Low power can achieve super super moulding effect.

PLC Control System

.

Advanced PLC control system and clearly screen display make the operation more convenient. Electrical components are made in famous factories, which can make a long time service.

Block samples

The machine can produce various hollow bricks, solid bricks and pavers by changing the moulds. The following bricks are somecommon brick types. At the same time, we can customize the brick moulds for you according to your specific requirements.

Related Products

Our Service

Factory

Hot Searches