- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Power:

-

1.1-11KW

-

Dimension(L*W*H):

-

According to the model

-

Weight:

-

100

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

SS304/SS316

-

Heating Type:

-

steam heating

-

Application:

-

oil, chemical, rubber, pesticide, dye, food

Quick Details

-

Capacity:

-

customized, 600L~20000L

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

jhenten

-

Voltage:

-

Customized

-

Power:

-

1.1-11KW

-

Dimension(L*W*H):

-

According to the model

-

Weight:

-

100

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

SS304/SS316

-

Heating Type:

-

steam heating

-

Application:

-

oil, chemical, rubber, pesticide, dye, food

Products Description

Feature

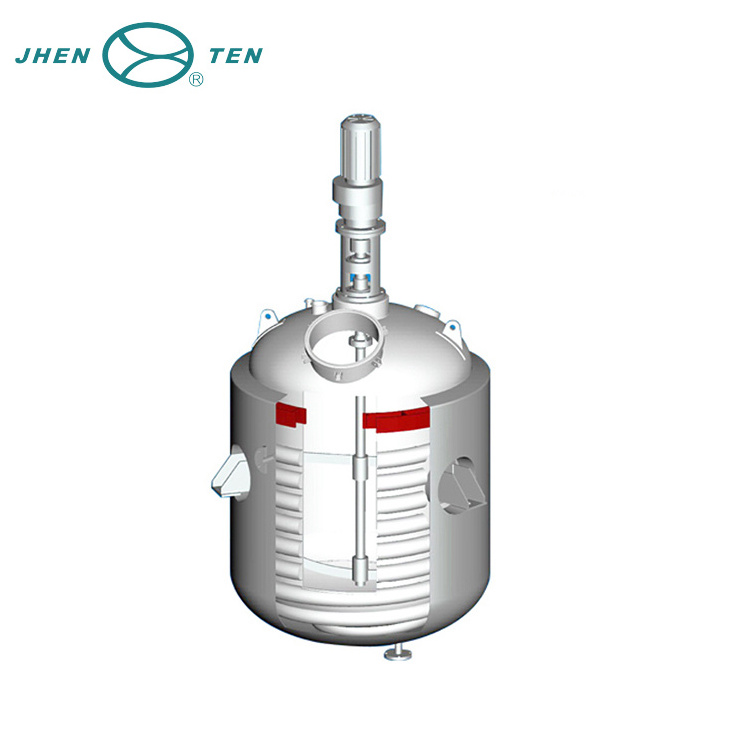

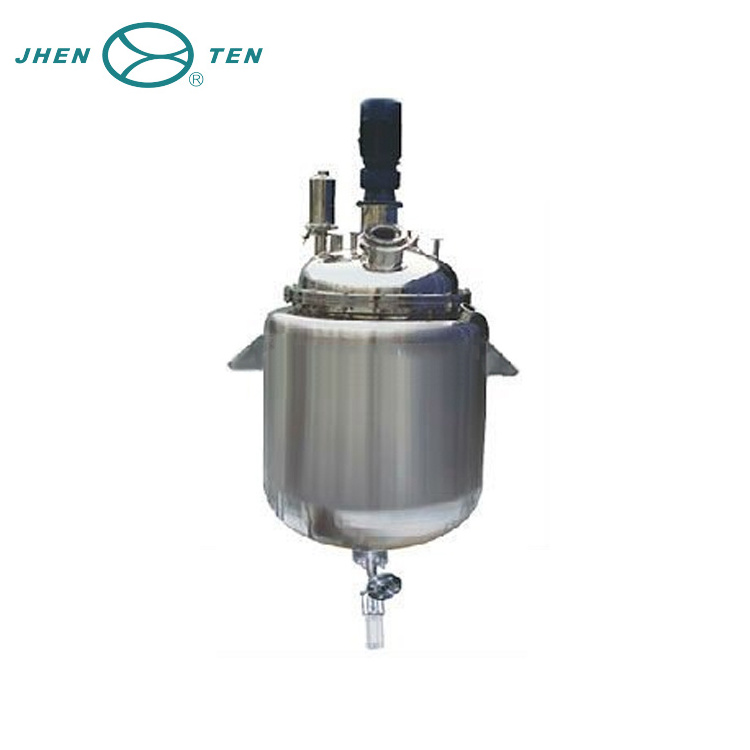

• Reactor made of 316L or 304 has excellent mechanical properties bearing high pressure, also it can withstand the force of the

massive solid materials during feeding process. It features rapid heating, high temperature resistant, corrosion resistance, no

rust, sanitary, no pollution etc.

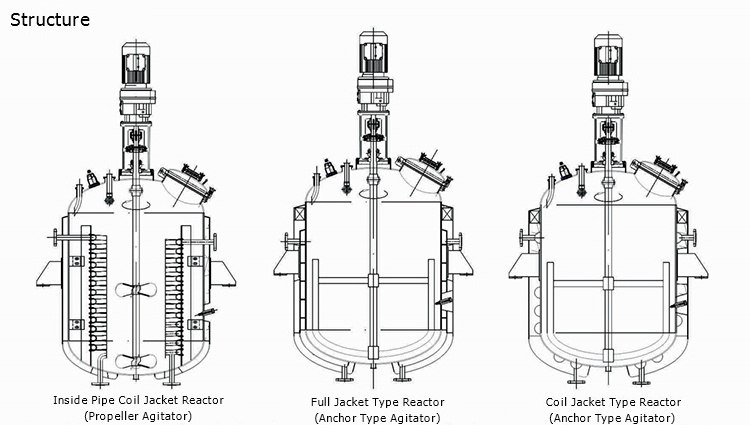

• Agitator with anchor type, frame type, impeller or turbine, using cycloidal reducer, gear reducer, and frequency control;

Mechanical seal sealing device meeting sanitary standard. full jacket, half pipe coil, cooling / heating coil structure available,

heating mode with steam, electric heating; heat conduction oil. Can be arbitrarily selected according to the user's technique.

• Reactor has 600L and 20000L, and other specifications, according to the actual requirement of customers.

Application

• Apply to petrochemical, fine chemicals, rubber industry, agricultural chemicals, colourants, pharmaceutics, food and beverage,

to complete the vulcanization, hydrogenation, alkylation, polymerization, condensation process

T ank Optional Configuration

Reactor can configure aseptic air filter, thermometer (Digital display or Dial type), PH meter, pressure gauge, steam

sterilization hole, sight glasses,sanitary manhole, liquid in-outlet, CIP cleaning ball, liquidometer and Liquid level control

system (Bearing module, non-contact ultrasonic, static pressuretransmitting device) and so on, also can configure as customer's requirement.

• Reactor made of 316L or 304 has excellent mechanical properties bearing high pressure, also it can withstand the force of the

massive solid materials during feeding process. It features rapid heating, high temperature resistant, corrosion resistance, no

rust, sanitary, no pollution etc.

• Agitator with anchor type, frame type, impeller or turbine, using cycloidal reducer, gear reducer, and frequency control;

Mechanical seal sealing device meeting sanitary standard. full jacket, half pipe coil, cooling / heating coil structure available,

heating mode with steam, electric heating; heat conduction oil. Can be arbitrarily selected according to the user's technique.

• Reactor has 600L and 20000L, and other specifications, according to the actual requirement of customers.

Application

• Apply to petrochemical, fine chemicals, rubber industry, agricultural chemicals, colourants, pharmaceutics, food and beverage,

to complete the vulcanization, hydrogenation, alkylation, polymerization, condensation process

T ank Optional Configuration

Reactor can configure aseptic air filter, thermometer (Digital display or Dial type), PH meter, pressure gauge, steam

sterilization hole, sight glasses,sanitary manhole, liquid in-outlet, CIP cleaning ball, liquidometer and Liquid level control

system (Bearing module, non-contact ultrasonic, static pressuretransmitting device) and so on, also can configure as customer's requirement.

|

Design Parameter

|

|

|

|

Design pressure

|

Tank body (-0.MPa~2.0MPa)

|

|

|

|

Jacket (ATM-0.6MPa)

|

|

|

Design temperature

|

Tank body and Jacket (0℃~160℃)

|

|

|

Material

|

|

|

|

Liner

|

304, 316L

|

|

|

Jacket

|

304

|

|

|

Insulation

|

Rockwool or polyurethane

|

|

|

Legs

|

304

|

|

|

Connection

|

|

|

|

In-outlet

|

Tri-clamp, Flange

|

|

|

Surface Finish

|

|

|

|

Finish type

|

Mechanical / electrolytic polishing, sand blasting, pickling

|

|

|

Polishing precision

|

Inner surface Ra≤0.4um

|

|

|

|

Outside surface Ra≤0.6um

|

|

|

Model

|

|

JTRFY-600

|

JTRFY-1000

|

JTRFY-2000

|

JTRFY3000

|

JTRFY-4000

|

JTRFY-5000

|

|||||

|

Effective volume(L)

|

|

600

|

1000

|

2000

|

3000

|

4000

|

5000

|

|||||

|

Tank

|

Diameter(mm)

|

Φ900

|

Φ1100

|

Φ1300

|

Φ1600

|

Φ1700

|

Φ1800

|

|||||

|

|

Height(mm)

|

900

|

1000

|

1500

|

1500

|

1800

|

1800

|

|||||

|

Mixng

|

Power (KW)

|

1.1

|

1.5

|

2.2

|

2.2

|

3

|

4

|

|||||

|

|

RPM(r/min)

|

200(propeller) / 60(anchor type) (Can adjust the design according to the customer's usage)

|

|

|

|

|

|

|||||

|

Model

|

|

JTRFY-6000

|

JTRFY-8000

|

JTRFY-10000

|

JTRFY-12000

|

JTRFY-15000

|

JTRFY-20000

|

|||||

|

Effective volume(L)

|

|

6000

|

8000

|

10000

|

12000

|

15000

|

20000

|

|||||

|

Tank

|

Diameter(mm)

|

Φ1900

|

Φ2000

|

Φ2200

|

Φ2400

|

Φ2600

|

Φ2800

|

|||||

|

|

Height(mm)

|

2000

|

2200

|

2400

|

2500

|

2700

|

3000

|

|||||

|

Mixng

|

Power (KW)

|

04

|

5.5

|

7.5

|

7.5

|

11

|

11

|

|||||

|

|

RPM(r/min)

|

200(propeller) / 60(anchor type) (Can adjust the design according to the customer's usage)

|

|

|

|

|

|

|||||

Recommend Products

Hot Searches