- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Slightly Oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JFY

-

Thickness:

-

0.6 - 15 mm

-

Grade:

-

A53(A,B)

-

Delivery Time:

-

7-15 days

-

Product name:

-

astm a53 pre galvanized steel pipe

-

Shape:

-

steel pipe

-

Surface:

-

Black Bright Galvanized Painted

-

Material:

-

Q235/Q235B/Q345/Q345B/SS400

-

Key words:

-

Square Tube

-

Technical:

-

welding pipe

-

Type:

-

round pipe, Welded Steel Pipe

-

Name:

-

steel pipe

-

Commodity:

-

all kinds of steel pipe

Quick Details

-

Section Shape:

-

Square

-

Surface Treatment:

-

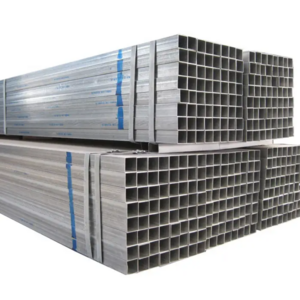

galvanized

-

Tolerance:

-

±5%

-

Oiled or Non-oiled:

-

Slightly Oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JFY

-

Thickness:

-

0.6 - 15 mm

-

Grade:

-

A53(A,B)

-

Delivery Time:

-

7-15 days

-

Product name:

-

astm a53 pre galvanized steel pipe

-

Shape:

-

steel pipe

-

Surface:

-

Black Bright Galvanized Painted

-

Material:

-

Q235/Q235B/Q345/Q345B/SS400

-

Key words:

-

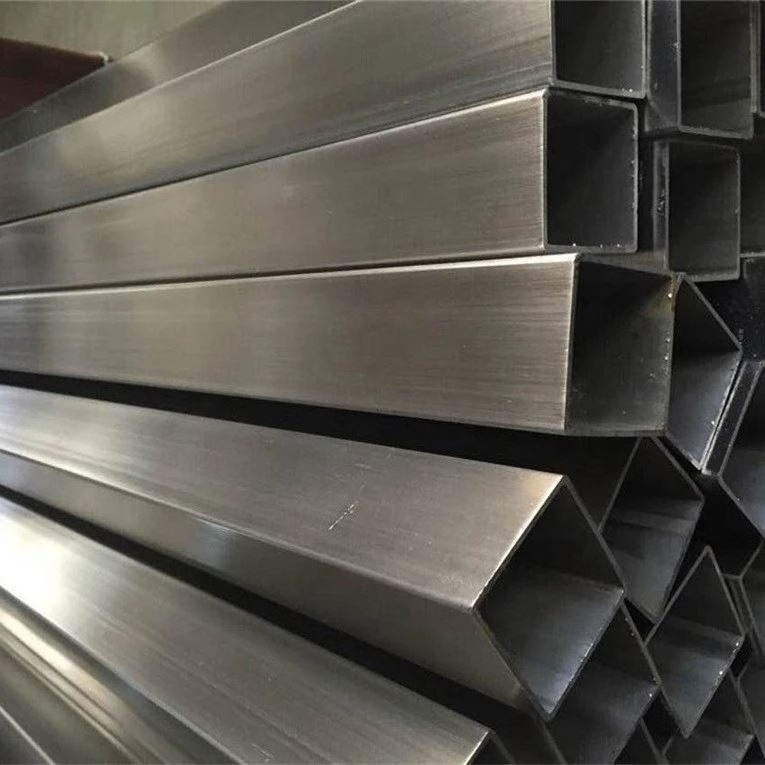

Square Tube

-

Technical:

-

welding pipe

-

Type:

-

round pipe, Welded Steel Pipe

-

Name:

-

steel pipe

-

Commodity:

-

all kinds of steel pipe

High Quality Selling Aluminum Stainless Carbon Steel Square Tube

Product Details

|

SPECIFICATIONS FOR STEEL PIPE

|

|

|

||

|

INTRODUCTION |

Product

|

steel pipe

|

||

|

|

Standard

|

ASTM,BS,GB,JIS,etc

|

||

|

|

Grade

|

SS400, ST37-2, A36, S235JRG1, Q235, Q345 etc

|

||

|

SPECIFICATIONS |

Product Keywords

|

steel pipe

|

||

|

|

manufacturing technique

|

Hot rolled(elementary) Can be processed again repeatedly

|

||

|

|

strength of extension

|

A36/420MPa S355JR/485MPa

|

||

|

Shipping |

Technique

|

welding pipe

|

||

|

|

Delivery Time

|

10~20days

|

||

|

|

Shipping

|

1)Shipping by containers

2)Shipping by bulk ship |

||

Production Process

Square tube production process

(1) The raw materials are strip coil, welding wire and flux. They must undergo strict physical and chemical inspections before being put into use.

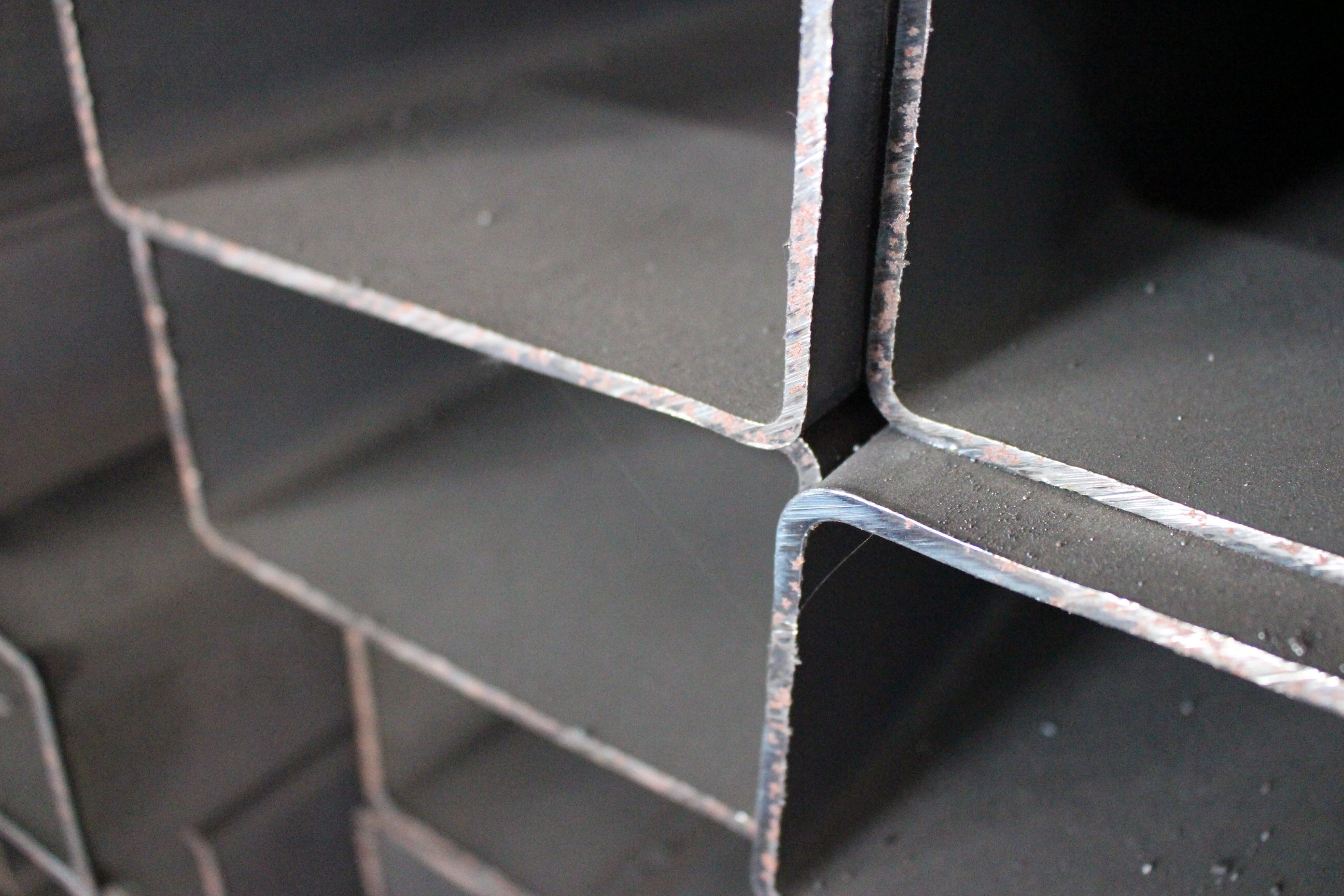

(2) The head and tail of the strip are butted by single wire or double wire submerged arc welding, and automatic submerged arc welding is used for repair welding after rolling into a square tube.

(3) Before forming, the strip is leveled, trimmed, planed, surface cleaned and conveyed and pre-bending.

(4) The electric contact pressure gauge is used to control the pressure of the cylinder on both sides of the conveyor to ensure the smooth conveying of the strip.

(5) Adopt external control or internal control roll forming.

(6) The welding seam gap control device is used to ensure that the welding seam gap meets the welding requirements, and the pipe diameter, the amount of misalignment and the welding seam gap are strictly controlled.

(7) Both internal welding and external welding use the American Lincoln welding machine for single wire or double wire submerged arc welding, so as to obtain stable welding specifications.

(8) The welded seams are all inspected by an online continuous ultrasonic automatic flaw tester, which ensures 100% non-destructive testing coverage of the spiral welds. If there is a defect, it will automatically alarm and spray the mark, and the production workers can adjust the process parameters at any time accordingly to eliminate the defect in time.

(9) Use an air plasma cutting machine to cut the square tube into single pieces.

(10) After cutting into a single square tube, each batch of three square tube heads shall undergo a strict first inspection system to check the mechanical properties, chemical composition, fusion status of the weld, surface quality of the square tube, and non-destructive testing to ensure that Only after the pipe-making process is qualified can it be officially put into production.

(11) The parts with continuous sonic flaw detection marks on the welds shall be re-examined by manual ultrasonic wave and X-ray. If they are indeed defective, after repairing, they shall undergo non-destructive inspection again until it is confirmed that the defects have been eliminated.

(12) The tube where the butt welding seam of the strip steel and the T-joint intersecting with the spiral welding seam are located shall be inspected by X-ray television or filming.

(13) Each square tube is tested by hydrostatic pressure, and the pressure is radially sealed. The test pressure and time are strictly controlled by the square tube water pressure microcomputer detection device. The test parameters are automatically printed and recorded.

(14) The pipe end is machined so that the verticality of the end face, the bevel angle and the blunt edge are accurately controlled.

Products Description

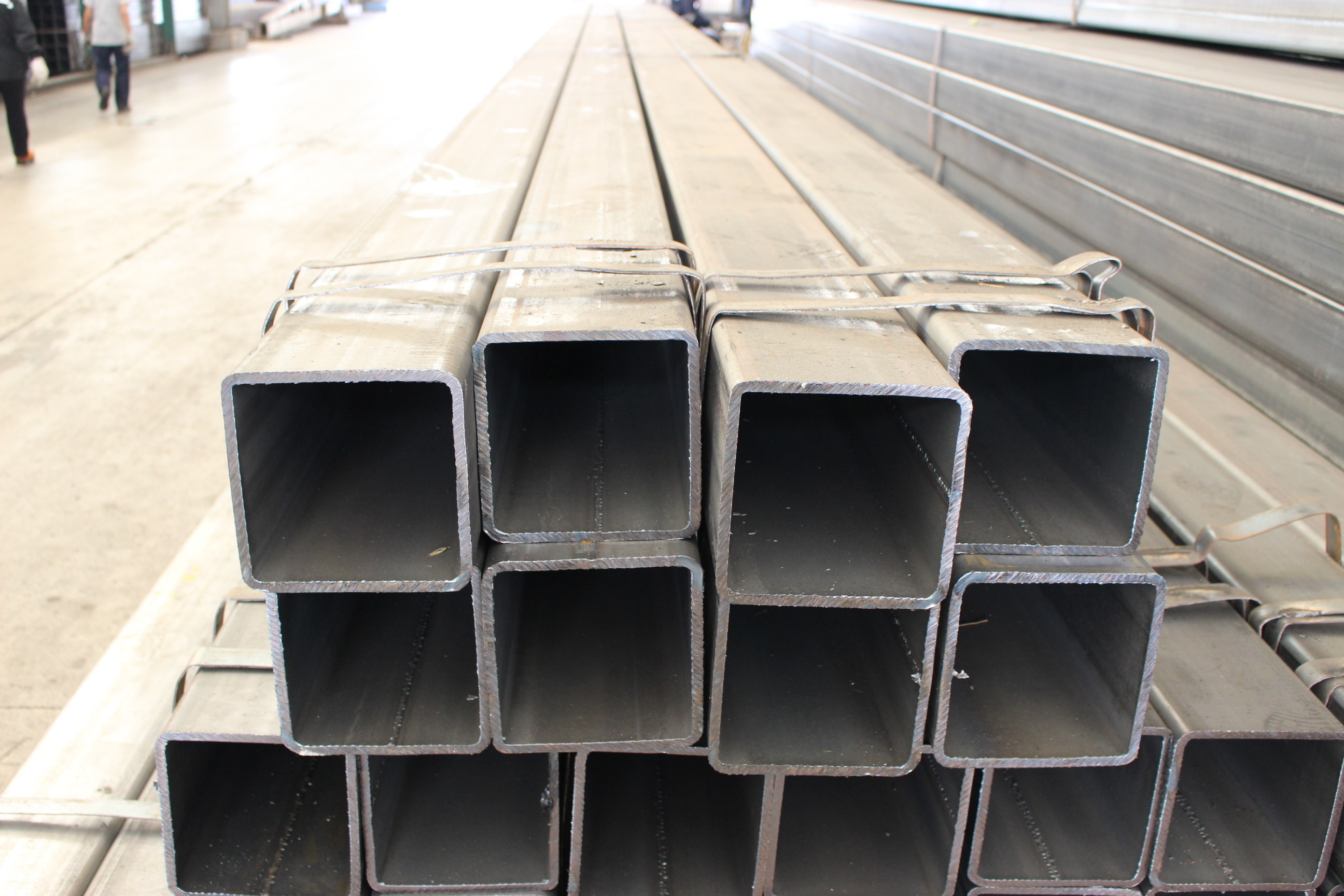

Rectangular pipe is a name for square pipe and rectangular pipe, that is, steel pipes with equal and unequal side lengths. It is made of strip steel after process treatment. Generally, the strip steel is unpacked, flattened, crimped, welded to form a round tube, and then rolled into a square tube from the round tube and then cut to the required length.

1) Seamless square pipe is a square steel pipe with four corners, which is a square steel pipe formed by cold drawing and extrusion of seamless steel pipe.

2) Welded square pipe, also called welded pipe, is a square pipe made of steel plate or strip steel after crimping and welding.

3) The quality of the seamless square tube is better and the price is more expensive. The welded square tube is welded by bending the plate. There is a high temperature during the welding process. The high temperature will affect the structure of the metal, and the mechanical properties are not as stable as the seamless steel tube.

4) Welded square tube is a hollow square section steel square tube, also known as hollow cold-formed steel. Shaped steel with square cross-section shape and size. In addition to the thickening of the wall thickness of the seamless square tube, its corner size and edge straightness reach or even exceed the level of the resistance welded cold-formed square tube.

Hot Searches