- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Arise

-

Product name:

-

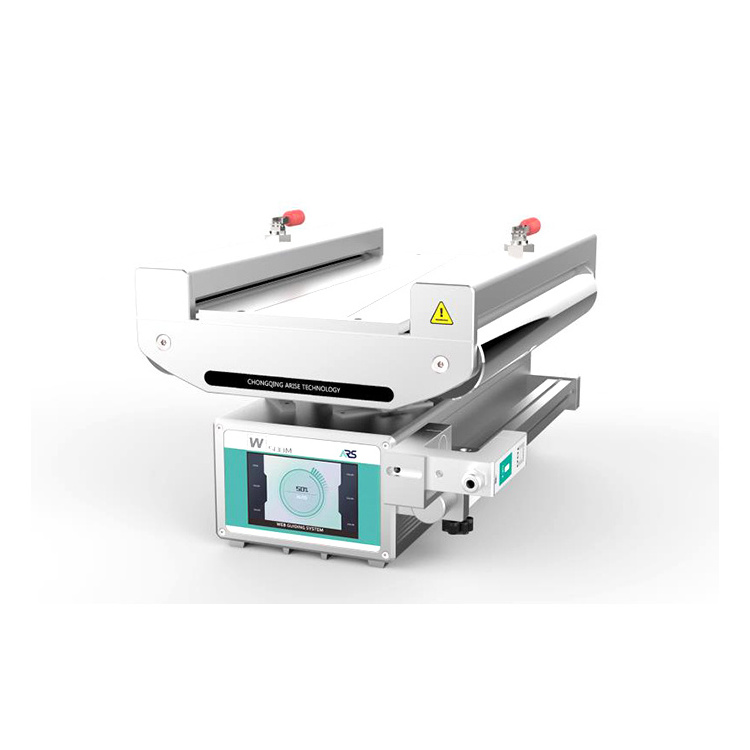

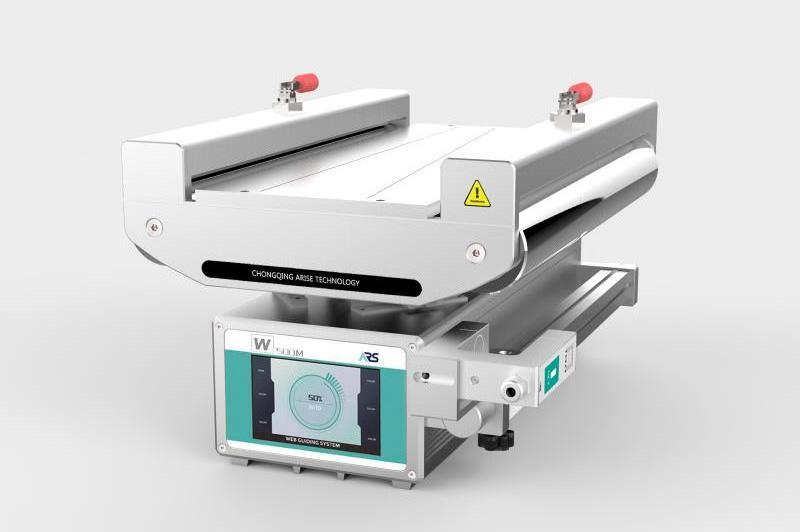

Web Guiding System With Splice

-

Model number:

-

W500

-

Type:

-

Full Touch Screen with Auto Splice

-

Feature:

-

Support photoelectric sensor, ultrasonic sensor, CCD sensor

-

Advantages:

-

Track the edge of the substrate

Quick Details

-

Condition:

-

New

-

Applicable Industries:

-

printing, label, coiled materials

-

Place of Origin:

-

China

-

Brand Name:

-

Arise

-

Product name:

-

Web Guiding System With Splice

-

Model number:

-

W500

-

Type:

-

Full Touch Screen with Auto Splice

-

Feature:

-

Support photoelectric sensor, ultrasonic sensor, CCD sensor

-

Advantages:

-

Track the edge of the substrate

| Features |

Support three working methods of line tracking, edge tracking, centering tracking, etc

|

| Description | Coil materials refer to long-sized continuous materials such as paper, film, sheet, non-woven fabric, metal foil, silk, thread, etc. In the process of uncoiling, technological processing, winding, etc, deviation of the coil materials may occur, due to the deviation of the coil itself or the processing machine. The Arise W500 all-in-one web guiding system machine provides a solution to reduce the occurrence of such situations. The system always tracks the position of the coil material during the production and makes corrections in real-time. |

| Advantages |

1. Track the edge of the substrate, correct the unevenness of the substrate when winding.

|

| Working Principle |

The web guiding system is a closed-loop controller. First, the sensor detects the edge or line of the coil, and the system automatically reads the deviation of the actual position and setting the position of the coil and converts the offset into an electrical signal. They send the signal to the controller. After that the signal is calibrated by the controller, it is outputted to the linear driver. The linear driver drives the deviation correction according to the magnitude of the signal. Then the guide mechanism adjusts the coil to the set position. The drive signal of the current drive is only proportional to the deviation of the coil, which makes it possible to provide precise control for various coils. |

| Main Applications |

The W500 web guide has been widely used in the applications of various industries and it is essential in industries such as packaging, printing, labels, building materials, paper pulp, metal processing, non-woven fabrics, corrugated paper processing, etc. Tire industry: molding machine, carcass cord, laminating drum common template correction, inner liner pre-correction, film blowing machine, industrial belt laminating machine. Packaging, printing and paper industries: satellite web printing machine, bump plate printing press machine, inspection machine, slitting rewinder, coating machine, etc. Battery industry: lithium battery coating machine, lithium battery slitting machine, lithium battery rolling die machine, battery stacking machine |

1. What should I do if there is technical problem?

-Please contact our technical support, we will help you solve the problem.

2.How to make payment?

-We accept 100% TT advance payment,and deliver within two days after receiving payment.