- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhuzhou China, Zhuzhou China

-

Brand Name:

-

MLD

-

Model Number:

-

Carbide CNC Inserts

-

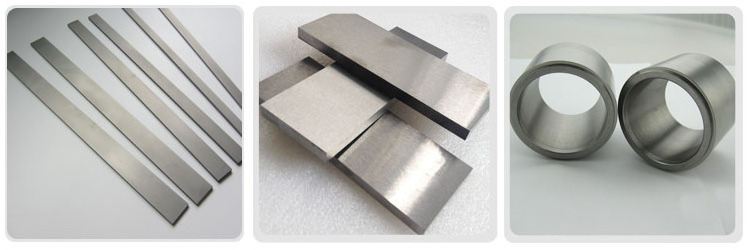

Material:

-

100% Virgin Raw Material

-

Finishing:

-

Fine Polished

-

Main Grades(ISO):

-

K10/K20/K30/K40 etc

-

Type:

-

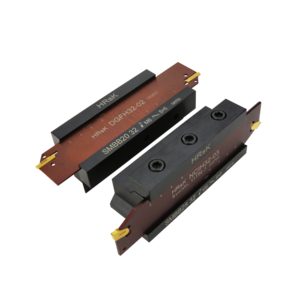

Internal External Turning Tool

-

Main Applications:

-

Metal Working Turning Tool

-

Certificate:

-

ISO9001:2008

-

Advantage:

-

High Wear Resistance

-

Feature:

-

High Performance Cutting

-

Service:

-

OEM ODM

Quick Details

-

Use:

-

Turning Tool

-

Hardness:

-

HRA92

-

Coating:

-

PVD CVD

-

Place of Origin:

-

Zhuzhou China, Zhuzhou China

-

Brand Name:

-

MLD

-

Model Number:

-

Carbide CNC Inserts

-

Material:

-

100% Virgin Raw Material

-

Finishing:

-

Fine Polished

-

Main Grades(ISO):

-

K10/K20/K30/K40 etc

-

Type:

-

Internal External Turning Tool

-

Main Applications:

-

Metal Working Turning Tool

-

Certificate:

-

ISO9001:2008

-

Advantage:

-

High Wear Resistance

-

Feature:

-

High Performance Cutting

-

Service:

-

OEM ODM

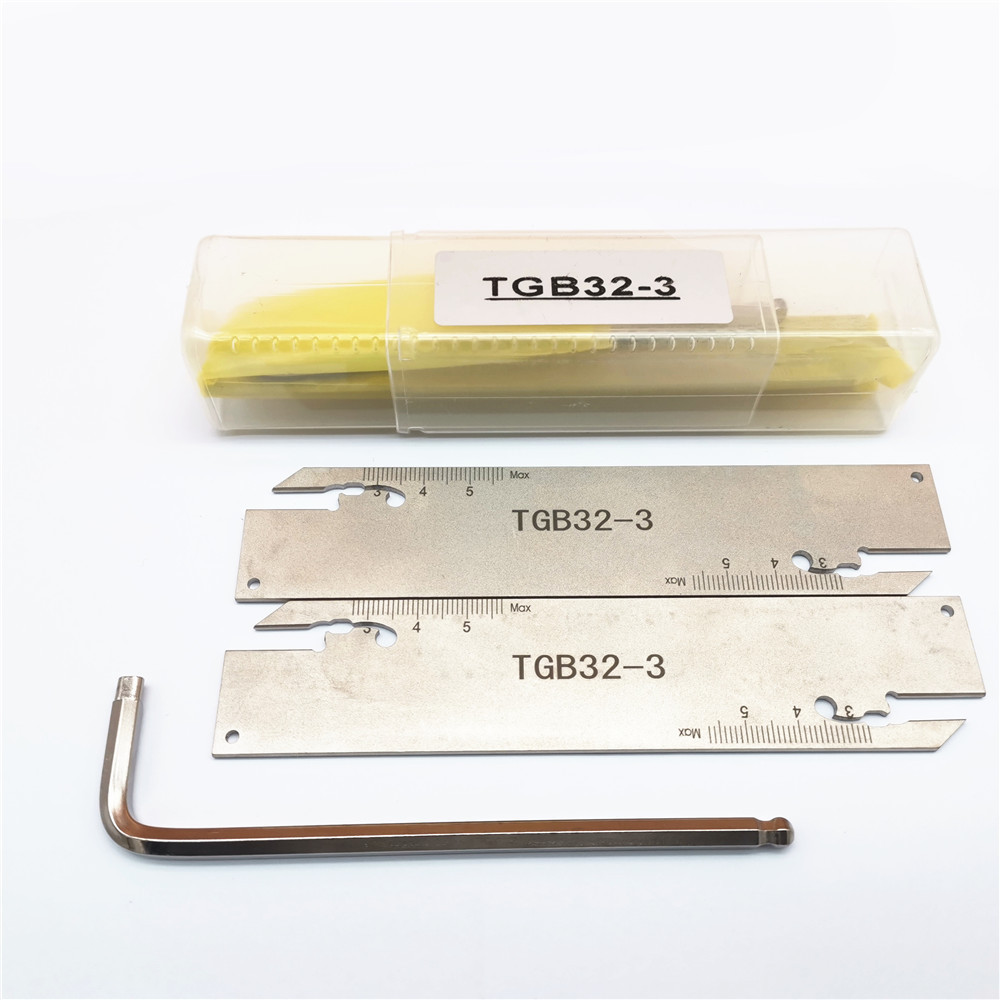

TGB Grooving Blade

Product Overview

Product De scription and Parameters

|

NO |

Chip Breaker |

Introduction |

Competitor (Chip Breaker) |

|

1 |

PM |

Double sided chip breaker for medium machining. Wide range of application in steel and cast iron. |

SANDVIK(PM) |

|

2 |

DF |

Double sided chip breaker with good chip control. Suitable for finishing and medium machining of steel and cast iron. |

SANDVIK(-PF), SECO(-MF1) |

|

3 |

DM |

Double sided chip breaker for medium machining. Wide range of application due to excellent balance of sharpness and cutting edge stability. |

SANDVIK(PM), SECO(MF2), KYOCERA(HQ) |

|

4 |

DR |

Double sided chip breaker with positive rake angle and stable cutting edge for light to medium roughing of steel and cast iron. |

SANDVIK (PR,QR) |

|

5 |

EF |

Double sided chip breaker with good chip control. Suitable for finishing and medium machining of steel and cast iron. |

KYOCERA(-CF) |

|

6 |

EM |

Double sided chip breaker with sharp cutting edge and large rake angle. Process reliable medium machining of stainless steel. |

TUNGALOY(TM) |

|

7 |

ER |

Double sided chip breaker with large rake angle for low cutting forces. Suitable for roughing of stainless steel. |

SANDVIK (MR,QR) |

|

8 |

LH |

Single sided chipbreaker for machining of cast aluminium alloys. Sharp cutting edge with positive rake angle. G-tolerance for high repeatability. |

KORLOY(AR) |

|

9 |

LC |

Single sided chip breaker with excellent cutting edge design. Sharp cutting edge with positive rake angle. G-tolerance for |

KORLOY(AK) |

|

10 |

HF |

Single sided chip breaker with good chip control. Suitable for finishing to medium machining of steel and cast iron. |

MITSUBISHI (FJ,FV), KYOCERA(CF) |

|

11 |

HM |

Single sided chip breaker for medium machining. Wide range of application due to excellent balance of sharpness and cutting edge stability. |

MITSUBISHI (FJ,FV), KYOCERA(CF) |

|

12 |

HR |

Single sided chip breaker with positive rake angle and stable cutting edge for light to medium roughing of steel and cast iron. |

SANDVIK (MR,QR,PR) |

|

13 |

TC |

Double sided chip breaker with surrounding cutting edge. Process reliable machining due to highest cutting edge stability. |

MITSUBISHI (GH) |

|

No. |

Grade |

ISO |

Grade description |

|

1 |

YBC301 |

P20 – P35 |

CVD coated P20–P35 carbide grade for medium operation to roughing of steel at lower cutting speed. |

|

2 |

YBC302 |

P20 – P35 |

CVD coated P20–P35 carbide grade for medium operation to roughing of steel at higher cutting speed. Optimal performance of wear resistance and toughness for a wide application field. |

|

3 |

YBM251 |

P20-P30 M15-M35 |

CVD coated P20–P30/M15–M35 carbide grade for medium to roughing operation in stainless steel and steel with wide application feld. Good wear resistance and capability against plastic deformation at normal cutting speed. |

|

4 |

YBM351 |

P25-P40 M25-M40 |

CVD coated P25–P40/M25–M40 carbide grade for roughing operation in stainless steel and steel. Good wear resistance and edge stability at normal cutting speed. |

|

5 |

YBG102 |

S05 – S15 |

PVD coated S05–S15 carbide substrate for fnishing to medium application of super alloy material, stainless steel and aluminum. Good wear resistance in a wide application field. |

|

6 |

YBG202 |

P10-P30 M10-M25 |

PVD coated P10–P30/M10–M25 carbide substrate for fnishing to medium application of stainless steel and steel (milling). Good wear resistance in a wide application field. |

|

7 |

YBG302 |

P15-P30 M25-M40 |

PVD coated P15–P30/M25–M40 carbide substrate for medium roughing application of stainless steel and steel (milling). Good wear resistance and toughness. |

|

8 |

YBG205 |

P10-P30 M20-M40 S15-S25 |

PVD multilayer coated P10–P30/M20–M40/S15–S25 carbide substrate for finishing to medium application of stainless steel, super alloy and steel (milling). Good wear resistance and thermal stability in a wide application field. |

|

9 |

YB9320 |

P10-P30 M20-M40 |

PVD multilayer coated P10–P30/M20–M40 carbide substrate for fnishing to medium application of stainless steel, super alloy and steel (grooving/milling). Optimized coating stability for higher wear resistance and thermal stability in a wide application field. |

Customized Solution