- Product Details

- {{item.text}}

Quick Details

-

Type:

-

High Feed Milling Tools

-

Coating:

-

Ni or black

-

Place of Origin:

-

Hunan, China

-

Applicable insert:

-

SPMT120408

-

Wrench:

-

T20

-

Hardness:

-

HRC40-45

-

Spare part manufacturer:

-

Taiwan/Korea/Switzerland

-

Radial tolerance:

-

0.03mm

-

Axial tolerance:

-

0.03mm

-

Holding handle tolerance grade:

-

H6

-

Feeler gauge for testing:

-

0.01mm

-

Sample offering:

-

yes

-

Function:

-

Milling Machine Tools

Quick Details

-

Diameter:

-

12-32

-

Overall Length:

-

100-200

-

Material:

-

42CrMo

-

Type:

-

High Feed Milling Tools

-

Coating:

-

Ni or black

-

Place of Origin:

-

Hunan, China

-

Applicable insert:

-

SPMT120408

-

Wrench:

-

T20

-

Hardness:

-

HRC40-45

-

Spare part manufacturer:

-

Taiwan/Korea/Switzerland

-

Radial tolerance:

-

0.03mm

-

Axial tolerance:

-

0.03mm

-

Holding handle tolerance grade:

-

H6

-

Feeler gauge for testing:

-

0.01mm

-

Sample offering:

-

yes

-

Function:

-

Milling Machine Tools

CNC Cutting Tools with High Speed Milling Tools mechanical workshop

High Speed Milling Cutter Description :

1: Can be used on CNC lathe machine .

2: Matched with ZCC SPMT120408 cnc inserts .

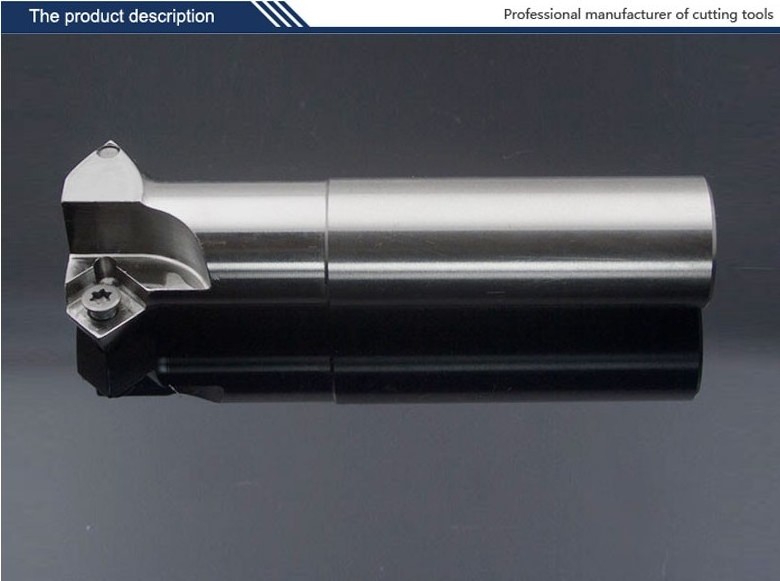

3: Spare part import from Taiwan/Korea/ Switzerland ,the hardness of screw is grade 12.9 .

4: Material 42CrMo ,long tool life , better wear-resistantce,strength and rigidity,high working efficiency.

5: Stable cutting ,smooth surface , high precision.

6: Using 0.01mm feeler gauge to insure the tightly connection between the inserts and the tool .

7: Cooperate with NIHONG-TECHNO ,adopt advanced heat treatment equipment, make sure the uniformity of the hardness(HRC40-45)

8: Processed with high precision CNC machining centre .

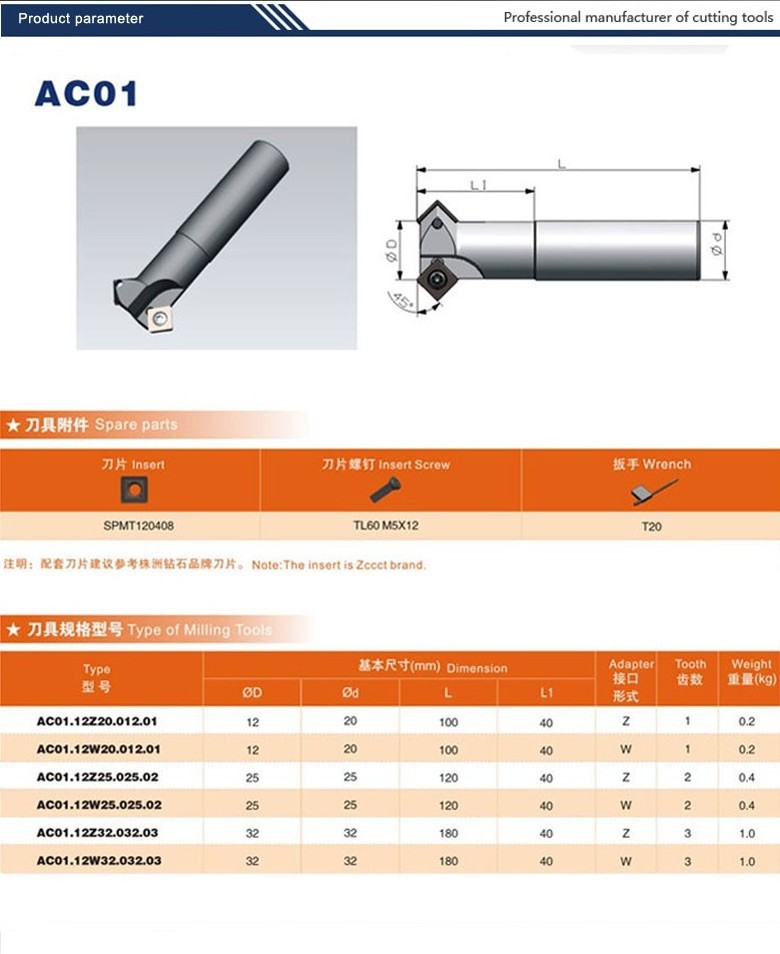

High Feed Milling Cutter Parameter :

|

Applicable Machine |

CNC Lathe Machine |

|

Stock

|

For standard, enough stock |

|

For non-standard , need to be customized |

|

|

Non-standard order |

Customize as request |

|

Laser Marking |

Can print logo and model number as request |

|

Suitable for steel , cast iron , non-ferrous metal cutting |

|

High Speed Milling Cutter Packaging:

transparent plastic bag for inner package;

blue plastic/corrugated box for outer package;

carton package for transportation.

can be customized as request.

High Speed Milling Cutter Shipping:

| Port |

Changsha/Shanghai/Guangzhou/Shenzhen/Hongkong

|

|

| Shipping |

By Air ,By Sea or By Express

|

|

|

Shipping Time

|

4-10days By Express |

Different Area many take different shipping days |

| 7-15days By Air | ||

| 25-55days By Sea | ||

| Trade Terms | FOB, CIF, EXW, CFR, DDU... | |

Pre-sales Service :

Our company is equipped with professional sales staff and application engineers, they can do the drawing confirmation and previous communication about the production and design of the tools based on your special requirements or the tools for OEM&ODM. At the same time, we can provide a full set of cutting tool processing scheme according to your processing requirements of all.

Sales Service:

We have ERP software management system, which enables us to make the reasonable arrangement and management based on your order requirements and delivery time. Meanwhile, sales staff can also know the status of orders anytime and communication with you timely. Besides, our company has passed the ISO9001 Quality Management System. Every working procedure, from the design of the products to the delivery, is arranged in strict accordance with the requirements of the Quality Management System, in order to guarantee the quality of our products.

After-sales Service:

Our professional sales staff will make return visits regularly, to know all the situation you have encountered during the application of the ordered products and then feedback to company. At the same time, we will arrange the returning and changing of the products timely if they have possible quality problems.

Technical Support:

We have a number of veteran tooling design engineers, thus can offer reasonable suggestions on the working procedure of your products, such as turning, milling, drilling etc. More importantly, we can design the products according to your requirements.