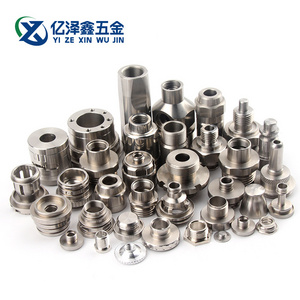

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

XINGTONG, XINGTONG

-

Product name:

-

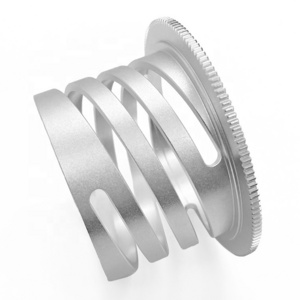

Cnc Maching Parts

-

Material:

-

Aluminum , Copper , Brass , Steel, Plastic Stainless Steel, Titanium

-

Surface treatment:

-

Anodized, Silk Screen, Plating, Powder Coated, Passivation, Polishing

-

Application:

-

Electronic, Auto, Electric Appliance, Electrical Machine, Toy, Medical

-

OEM/ODM:

-

OEM ODM CNC Milling Turning Machining Service

-

MOQ:

-

100 Pcs

-

Tolerance:

-

0.005mm

-

Process:

-

Cnc Machining + Surface Treatment

-

Quality control:

-

100% Inspection

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, Plastic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XINGTONG, XINGTONG

-

Product name:

-

Cnc Maching Parts

-

Material:

-

Aluminum , Copper , Brass , Steel, Plastic Stainless Steel, Titanium

-

Surface treatment:

-

Anodized, Silk Screen, Plating, Powder Coated, Passivation, Polishing

-

Application:

-

Electronic, Auto, Electric Appliance, Electrical Machine, Toy, Medical

-

OEM/ODM:

-

OEM ODM CNC Milling Turning Machining Service

-

MOQ:

-

100 Pcs

-

Tolerance:

-

0.005mm

-

Process:

-

Cnc Machining + Surface Treatment

-

Quality control:

-

100% Inspection

|

Material

|

Metal: Aluminum , Copper , Brass , Steel, Stainless Steel, Titanium And Etc.

Plastic: Abs, Pom, Pp, Pu, Pc,pa66, Pmma, Pvc, Pve, Nylon And Etc |

|

Surface Treatment

|

Anodized, Bead Blasted, Silk Screen, Pvd Plating, Zinc/nickel/chrome/titanium Plating, Brushing, Painting, Powder Coated,

Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/etch/engrave Etc. |

|

Tolerance

|

0.005 mm

|

|

Equipmets

|

Cnc Punching Machines, Cnc Milling Machines, Cnc Turning Machines,cnc Machining Center, Automatic Lathes, Linear Cutting, Grinding

Machine Etc. |

|

Applocation

|

Electronic, Auto, Electric Appliance, Electrical Machine, Toy, Medical Treatment Spare Metal Parts,loudspeaker Box, Furniture And

Fitness Equipment And Other Industries. |

|

Sampling Time

|

1 - 3 Days

|

|

Delivery Time

|

15 - 30 Days

|

Click here

to get

samples.

1. Are you a manufacturer or a trading company?

We are a factory with 2500+ square meters located in Shenzhen, China.

2.How to customize samples?

You provide drawings (CAD, PDF, STP) or samples, indicating the processing

quantity of work, material, precision and tolerance, surface treatment and other requirements. Customer service will give you a quotation after receiving it.

3.How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

4. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

5: Is it possible to know how are my products going on without visiting your company?

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

6. How do you control the quality?

(1) Material inspection--Check the material surface and roughly dimension.

(2) Production first inspection--To ensure the critical dimension in mass production.

(3) Sampling inspection--Check the quality before sending to the warehouse.

(4) Pre-shipment inspection--100% inspected by QC assistants before shipment.

Hot Searches