Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BOBO

-

Voltage:

-

220V or CUSTOMIZED

-

Power:

-

33kW

-

Dimension(L*W*H):

-

3910*1600*1430mm

-

Weight:

-

10 kg

-

Warranty:

-

12 months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Diameter of round tubes:

-

800mm ~ 2000mm.

-

Max. Tube length:

-

8000mm.

-

Thickness of strip:

-

2.0mm-2.5mm

-

Width of strip:

-

175mm

-

Strip speed:

-

1~30m/min, adjustable

-

Suitable strip material:

-

galvanized steel

-

Control system:

-

Mitsubishi inverter

-

Driving system:

-

Spiral subulate gear type decelerator

-

Material of forming rollers:

-

GCr15 bearing steel, quenched, HRC58-62

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

ISO,CE

Quick Details

-

Pipe Material:

-

Stainless steel

-

Production Capacity:

-

0-20m/min adjustable

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOBO

-

Voltage:

-

220V or CUSTOMIZED

-

Power:

-

33kW

-

Dimension(L*W*H):

-

3910*1600*1430mm

-

Weight:

-

10 kg

-

Warranty:

-

12 months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Diameter of round tubes:

-

800mm ~ 2000mm.

-

Max. Tube length:

-

8000mm.

-

Thickness of strip:

-

2.0mm-2.5mm

-

Width of strip:

-

175mm

-

Strip speed:

-

1~30m/min, adjustable

-

Suitable strip material:

-

galvanized steel

-

Control system:

-

Mitsubishi inverter

-

Driving system:

-

Spiral subulate gear type decelerator

-

Material of forming rollers:

-

GCr15 bearing steel, quenched, HRC58-62

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

ISO,CE

Product Description

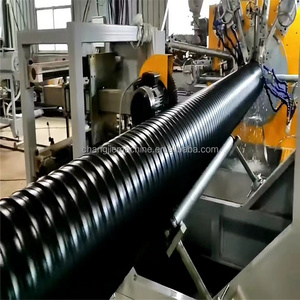

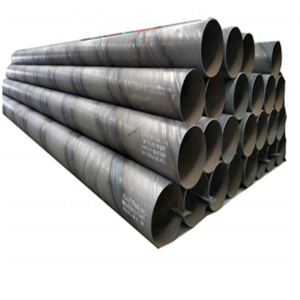

Spiral corrugated culvert pipe forming machine

The Spiral corrugated culvert pipe forming machine is used to form the steel pipe with reinforced rib for drainage pipe, post tension pipe purpose, which is widely used in drain storm, bridge construction, etc.

Title goes here.

* Special welded steel mould, light & long life.

* Large diameter range for change

* Auto unloading rack, low labor cost

* Large diameter range for change

* Auto unloading rack, low labor cost

Main technical data of the Spiral corrugated culvert pipe forming machine

|

No.

|

Parameter

|

Data

|

|

1

|

Model

|

BPT-2000

|

|

2

|

Diameter range

|

800-2000mm

|

|

3

|

Strip width

|

175mm

|

|

4

|

Strip thickness

|

2.0-2.5mm

|

|

5

|

Driving system

|

Spiral subulate gear type decrlerator

|

|

6

|

Control system

|

PLC control

|

|

7

|

Feeding speed

|

1~30m/min

|

|

8

|

Motor power

|

about 30 KW

|

FAQ

1. Q: What is the power supply of the machine?

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

Packing and Shipping

Packaging:

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

Our Services

1. Professional and patient consulting service to help you find the suitable solution.

2. Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3. Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4. Free training and accommodation in our plant during machine inspection. Or photos and video of the machine and package for

your confirmation before shipment.

5. Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6. For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7. For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original

cost after that

2. Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3. Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4. Free training and accommodation in our plant during machine inspection. Or photos and video of the machine and package for

your confirmation before shipment.

5. Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6. For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7. For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original

cost after that

Hot Searches