- Product Details

- {{item.text}}

Quick Details

-

Shelf Life:

-

12 months

-

Apperance:

-

liquid

-

viscosity:

-

adjustable

-

hardness:

-

0 shore A

-

mix ratio:

-

1:1 or 10:1

-

Delivery time:

-

7-10 Days

-

Payment Terms:

-

T/T

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Inibaba

-

Color:

-

Transparent, blue, adjustable

-

Shelf Life:

-

12 months

-

Apperance:

-

liquid

-

viscosity:

-

adjustable

-

hardness:

-

0 shore A

-

mix ratio:

-

1:1 or 10:1

-

Delivery time:

-

7-10 Days

-

Payment Terms:

-

T/T

Products Description

Description

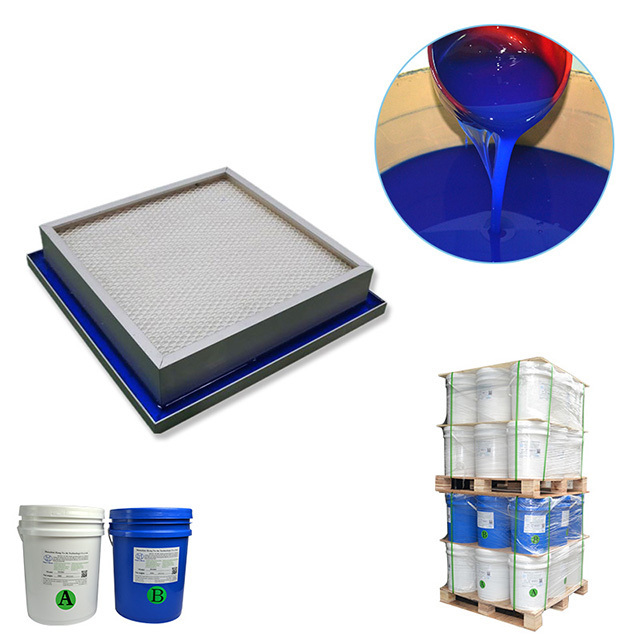

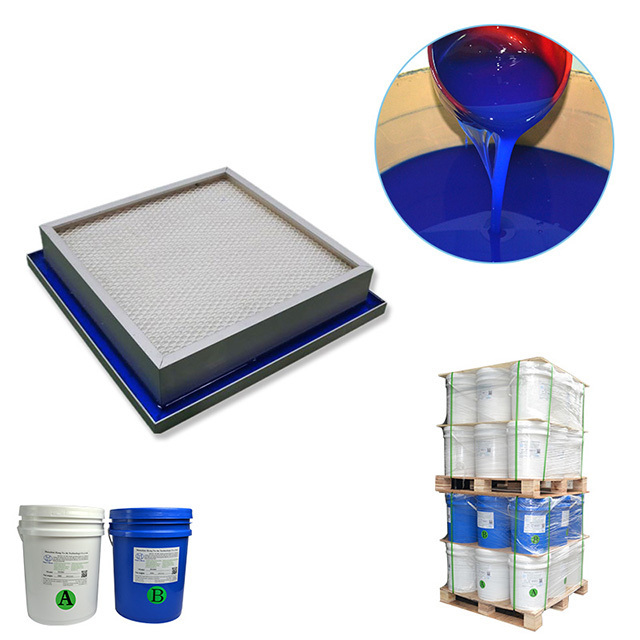

platinum base silicone softest silicone glue air filter potting silicone flowable silicone rubber

Silicone gel for air filter sealing is a low viscosity adhesive gel, it's a liquid sealing material, two parts encapsulating adhesive. This product will not release low molecules in the curing reaction, it's food grade encapsulation material.

Silicone gel for air filter sealing is a low viscosity adhesive gel, it's a liquid sealing material, two parts encapsulating adhesive. This product will not release low molecules in the curing reaction, it's food grade encapsulation material.

Application and Advantages

Inibaba's INI-9400 is mainly used for air filter potting, and can be applied to the surface of PC (poly carbon), PP, ABS, PVC and other materials and metals (aluminum, iron, copper, zinc).

Silicone gel is also used for encapsulating optical electronics, LCD, and sealing of precision electronic components.

They are also widely used in plane bonding, sealing and repair under high temperature, such as air filter sealing,

high-temperature oven, high-temperature air filter bonding and sealing of induction cooker and other high temperature equipment.

Advantages:

* This product has good adhesion with aluminum, galvanized plate, stainless steel, etc,

* The shrinkage is small and no corrosion. The cured gel has self-adhesive and self healing property, elastic recovery is good

* Excellent weather resistance, corrosion resistance, waterproof, moisture-proof, high temperature and low temperature resistance, no deformation.

* It can absorb the stress produced by thermal expansion and cold contraction without cracking, and has good automatic recovery sealing effect.

*Food grade potting material, good sealing, insulation, shockproof

Inibaba's INI-9400 is mainly used for air filter potting, and can be applied to the surface of PC (poly carbon), PP, ABS, PVC and other materials and metals (aluminum, iron, copper, zinc).

Silicone gel is also used for encapsulating optical electronics, LCD, and sealing of precision electronic components.

They are also widely used in plane bonding, sealing and repair under high temperature, such as air filter sealing,

high-temperature oven, high-temperature air filter bonding and sealing of induction cooker and other high temperature equipment.

Advantages:

* This product has good adhesion with aluminum, galvanized plate, stainless steel, etc,

* The shrinkage is small and no corrosion. The cured gel has self-adhesive and self healing property, elastic recovery is good

* Excellent weather resistance, corrosion resistance, waterproof, moisture-proof, high temperature and low temperature resistance, no deformation.

* It can absorb the stress produced by thermal expansion and cold contraction without cracking, and has good automatic recovery sealing effect.

*Food grade potting material, good sealing, insulation, shockproof

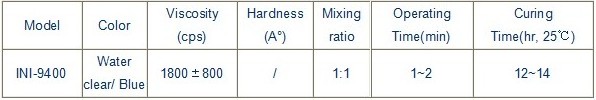

Parameter

Free Sample for your test.

Free Sample for your test.

Operation Instruction

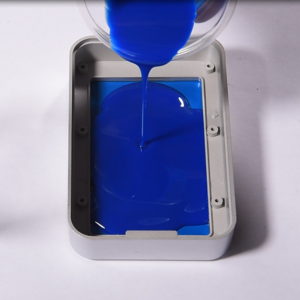

1.Stir part A and part B with right mixing ratio evenly. And get the mixture for vacuum-pumping. (If there is no vacuumizer,you can just pour the mixture slowly from the corner so that less bubbles caused).

2. Enclose the product (the original model) with four plastic plates or wooden plates.

3. Clean your products and brush a layer of release agent(detergent or soap water) on your product.

4. Pour the mixture with correct mixing ratio into the model frame.

After about 2-4 hours, when the silicone cured, get out the original model, and there you get a finished addition cured silicone mold .

Warm tips :

1. As addition cure silicone is a kind of platinum cure system ,which will be easy to cause uncure problem ,so Kindly follow the

tips below :

*Do not mix with liquid condensation silicone rubber or even the tool which used for condensation silicone

*Do not mix with organic matter which contains N, S, P organics and ionic compound like Sn, As,Hg, Ph,

*Do not add any pigment or powder into the addition cure silicone rubber without any testing to prevent uncure problem

2. Enclose the product (the original model) with four plastic plates or wooden plates.

3. Clean your products and brush a layer of release agent(detergent or soap water) on your product.

4. Pour the mixture with correct mixing ratio into the model frame.

After about 2-4 hours, when the silicone cured, get out the original model, and there you get a finished addition cured silicone mold .

Warm tips :

1. As addition cure silicone is a kind of platinum cure system ,which will be easy to cause uncure problem ,so Kindly follow the

tips below :

*Do not mix with liquid condensation silicone rubber or even the tool which used for condensation silicone

*Do not mix with organic matter which contains N, S, P organics and ionic compound like Sn, As,Hg, Ph,

*Do not add any pigment or powder into the addition cure silicone rubber without any testing to prevent uncure problem

Why Choose us

1. Powerful factory with a production capacity of 9000 per day

2. High-end research and development (free sample)

Being a leading liquid silicone manufacturer in China, we have a professional R&D team and QC team(12 experts ) and our product is RoHS, MSDS, ISO, REACH, UL approved, so there is no need to worry about the quality.

Being a leading liquid silicone manufacturer in China, we have a professional R&D team and QC team(12 experts ) and our product is RoHS, MSDS, ISO, REACH, UL approved, so there is no need to worry about the quality.

3,Efficient service

We can provide free training of silicone technique and free silicone samples. we have a professional sales team who will solve your problems patiently. Besides, with efficient logistics distribution system, you could get you goods earlier. Last, good after-sales service,we build long term cooperation relationship, once there is quality problem, we could solve right away. More importantly, return and exchange are accepted while quality problems occurred

We can provide free training of silicone technique and free silicone samples. we have a professional sales team who will solve your problems patiently. Besides, with efficient logistics distribution system, you could get you goods earlier. Last, good after-sales service,we build long term cooperation relationship, once there is quality problem, we could solve right away. More importantly, return and exchange are accepted while quality problems occurred

Certifications

Package

1kg/drum,5kg/drum, 20kg/drum,25kg/drum, 200kg/drum.

SHELF LIFE

Twelve (12) months from date of shipment when stored at 25°C in original unopened packages

1kg/drum,5kg/drum, 20kg/drum,25kg/drum, 200kg/drum.

SHELF LIFE

Twelve (12) months from date of shipment when stored at 25°C in original unopened packages

We can provide the free sample, more details about silicone rubber, pls contact Ms Lisa at:

Mobile/ Whatsapp/: +86 188 1670 2967

Wechat: + 86 188 1670 2967 or A108059

E-mail: lisasilicone(at)inibaba(dot)com

Twitter/Facebook:lisasilicone

Mobile/ Whatsapp/: +86 188 1670 2967

Wechat: + 86 188 1670 2967 or A108059

E-mail: lisasilicone(at)inibaba(dot)com

Twitter/Facebook:lisasilicone

Hot Searches