- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

H136

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Honscn

-

Product name:

-

customized stainless steel dowel pins steel thread pin and shaft

-

Application:

-

Heavy Industry, Water Treatment, Retail Industry, Food & Beverage

-

Surface treatment:

-

Zinc plating,Nickel plating,chromate plating,anodize

-

Certificate:

-

ISO9001:2008

-

Size:

-

As per drawing

-

Packing:

-

PE Bag+Carton

-

Sample:

-

free samples if have stock

-

Delivery time:

-

7-10 days after confirmed order

-

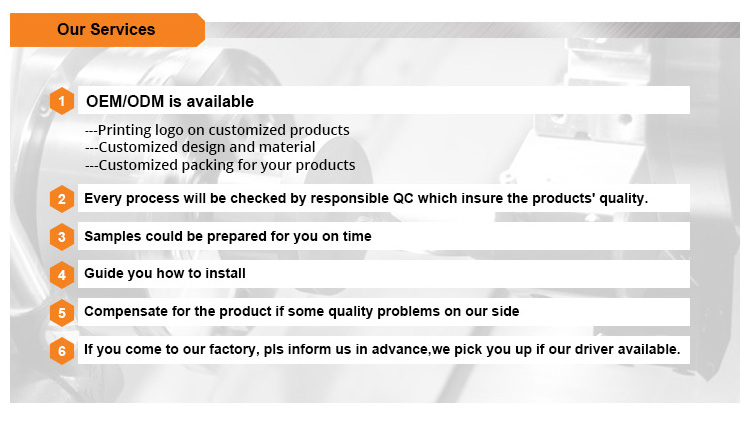

Service:

-

OEM Customized Services

Quick Details

-

Weight (KG):

-

0.05

-

Material:

-

Stainless Steel, Steel, Brass, Aluminum, Brass, Copper, Carbon steel, Stainless steel, Steel alloy

-

Torque Capacity:

-

As request

-

Model Number:

-

H136

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Honscn

-

Product name:

-

customized stainless steel dowel pins steel thread pin and shaft

-

Application:

-

Heavy Industry, Water Treatment, Retail Industry, Food & Beverage

-

Surface treatment:

-

Zinc plating,Nickel plating,chromate plating,anodize

-

Certificate:

-

ISO9001:2008

-

Size:

-

As per drawing

-

Packing:

-

PE Bag+Carton

-

Sample:

-

free samples if have stock

-

Delivery time:

-

7-10 days after confirmed order

-

Service:

-

OEM Customized Services

Why Choose Us

Specification

|

Main Material

|

Brass, Copper, Carbon steel, Stainless steel, Steel alloy

Aluminum alloy .etc |

|

|

Standard

|

ISO, JIS, GB, ANSI, BSW, DIN or non standard as customize

|

|

|

Surface Treatment

|

Zinc plating,Nickel plating,chromate plating,anodize

as per customer's requirement

|

|

|

Tolerance

|

+/-0.01mm to +/-0.005mm

|

|

|

dowel pin Size

|

M2-M16 as you request

|

|

|

Package

|

PP bag , Carton ,box or according to customer's requirements

|

|

|

Production Equipment

|

1.CNC Machining Center

2.CNC Lathe 3.CNC Milling Machine 4.Precision Cutting Machine |

|

|

|

||

Product Details

Lathe Parts Dowel Pin

Our factory can provide all. Pls send details you need. We evaluate for you soon.

1. Competitive factory price

2. Provide samples for test

3. Lead time: 10-12 days

4. 100% well control tolerance

5. Provide drawing for approval before produce

2. Provide samples for test

3. Lead time: 10-12 days

4. 100% well control tolerance

5. Provide drawing for approval before produce

Precise Tolerances we can do

1.Shaft diameter below 6mm and maximum pore size tolerance up to 0.003mm

2.Shaft diameter larger than 6mm and pore size tolerance is 0.005mm

3.Linearity below 100mm distance etc, tolerance is up to 0.005mm

4.100mm or more distance linear tolerance is up to 0.01mm

5.A form tolerance is up to 0.003 - 0.005mm

6.Position tolerance is up to 0.01mm.

2.Shaft diameter larger than 6mm and pore size tolerance is 0.005mm

3.Linearity below 100mm distance etc, tolerance is up to 0.005mm

4.100mm or more distance linear tolerance is up to 0.01mm

5.A form tolerance is up to 0.003 - 0.005mm

6.Position tolerance is up to 0.01mm.

Machining Process

Clients Feedback

product application

Hot Searches