- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YEJIA

-

Car Model:

-

all the cars

-

Wattage:

-

9999999999 wattage

-

Product name:

-

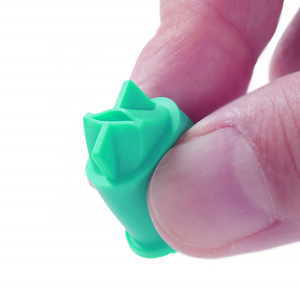

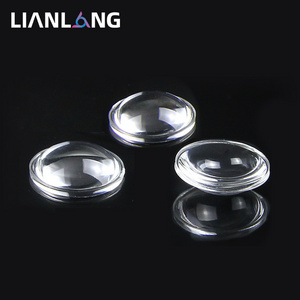

Silicone Lens

-

Usage:

-

For Car Lighting

-

Color:

-

Transparent

-

Transmissivity:

-

94%

-

Material:

-

Silicone optical material

-

Hardness:

-

72 Shore A

-

Machine:

-

ARBURG Horizontal LSR Injection Molding Machine

-

Mold Type:

-

LSR Injection Molding

Quick Details

-

OE No.:

-

Mazda

-

Warranty:

-

on line

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YEJIA

-

Car Model:

-

all the cars

-

Wattage:

-

9999999999 wattage

-

Product name:

-

Silicone Lens

-

Usage:

-

For Car Lighting

-

Color:

-

Transparent

-

Transmissivity:

-

94%

-

Material:

-

Silicone optical material

-

Hardness:

-

72 Shore A

-

Machine:

-

ARBURG Horizontal LSR Injection Molding Machine

-

Mold Type:

-

LSR Injection Molding

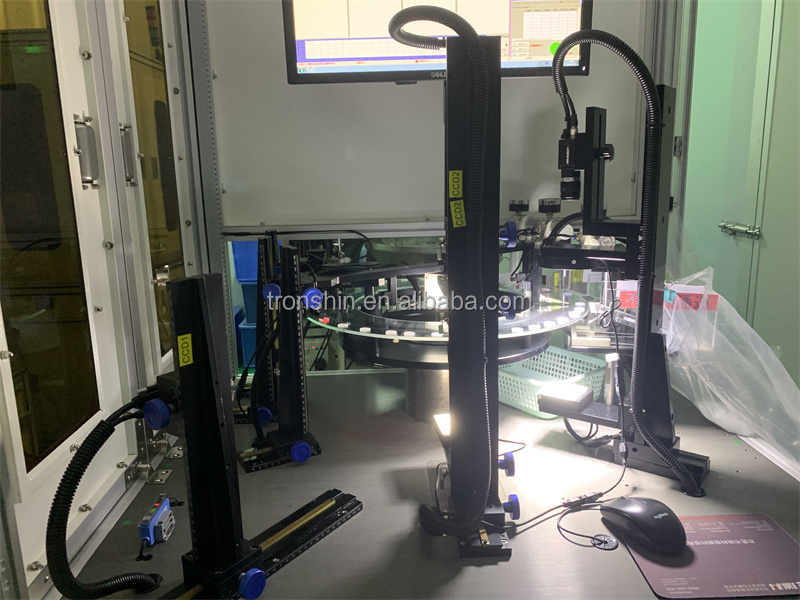

Company Advantages

Company Presentation

YEJIA

founded in 2009, we focus on R&D and production of silicone rubber products for over a decade. We have 6,000 square meter production workshops, 100,000 clean production workshop and painting workshop. With In-house precision mold design and mold making department. Our main products are silicone Electronic Waterproof Precision Parts, Silicon Lens, Silicone Valves, silicone SmartWearable products, silicone Medical and Beauty products, Other Custom Silicone Products. As Long-term Supplier for Fortune 500 Enterprises, at same time, we also approved ISO9001, ISO14001, ISO13485, IATF16949 Certifications and we are also Green Partner of SONY.

Production Workshop

2. Imported high-precision production equipment.

Testing Center

Independent Mold Room

2. Mold manufacturing accuracy controlled within 0.001mm.

Professional Engineering Team

Complete Certifications

2.For the silicone valves, we have EU food contact material certification and One Way Silicone Valve Patent.

3. Regarding to the materials of silicone valves, we have FDA certification, LFGB certification, ISO10993 certification and Biocompatibility report.

Advantages Of Silicone Lenses

Optical Properties

Better transparency and dispersion than plastic

•94% transmittance

•Haze<1%

•Abbe’s number is about 50

•Color persistence

•Anti-yellowing

Weather Resistance

Optical properties can be maintained under strict conditions to meet higher application requirements.

•High temperature stability, even above 150°C

• UV resistant

•Resistant to micro cracks

• Fire rating equivalent to UL 94 V-1

Free Design

Liquid silicone rubber has excellent processing properties, especially in the fields of LED lights and optical lenses:

•Design freedom for lighting optics

•High mobility helps achieve complex microstructure designs

•Integrated design with over-molding of other materials

•Lightweight product design

The Workflow Of Silicone Lens

Application

Silicone Lens For Outdoor Lighting

Silicone Lens For Car Lighting

Silicone Lens For Backlighting

Cooperate Optical Material Supplier

Dow Corning

MOMENTIVE

WACKER

DONESON

Details Images

FAQ

Q: Are you a manufacturer or a trading company?

A: We are a manufacturer with a workshop of about 10000 square meters.

Q: Can you provide free samples?

A: Free samples can be provided for quality checking, freight cost need be charged.

Q: What are the advantages of YEJIA to produce

silicone l

enses

?

A: YEJIA started producing silicone lenses in 2011, we also have professional engineering team, precision mold manufacturing department and perfect quality control department, a 100,000-level clean production workshop, and has passed ISO9001, ISO13485, IATF16949 and ISO14001 certifications.

Q: What is your MOQ for silicone lenses?

A: Our moq is 1000 pcs, the final quotation shall prevail.

Q: What information do I need to provide for custom silicone lens?

A: Please provide 2D and 3D drawings (STP format) or actual samples, then our engineering team will provide DFM for your confirmation.

Q: What is the lead time for custom silicone lens?

A: For prototype molds, the lead time for silicone lenses is about 7-15 working days; for production molds, the lead time is about 15-45 working days; Production time is about 15 days after samples confirmed.

Q: Can you provide proof of raw materials?

A; Yes, we can provide MSDS, reports for confirmation.

Q: Can i visit your factory?

A: Of course, highly welcome.

Hot Searches