- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

*

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GOFAR MACHINERY

-

Dimension(L*W*H):

-

700*350*2200

-

Weight:

-

100 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Function:

-

FILLING MACHINE

-

Filling speed:

-

1200BPH

-

Filling head:

-

2--6

-

Product name:

-

quantitative filler Laundry Liquid filling machine

-

Keywords:

-

Liquid Filling machine

-

Advantage:

-

High Effiency

-

Feature:

-

High Precision Filling Level

-

Control:

-

PLC+ Touch Screen

Quick Details

-

Machinery Capacity:

-

400BPH, 500BPH, 1000BPH

-

Packaging Material:

-

Plastic, Wood

-

Filling Material:

-

Water

-

Filling Accuracy:

-

*

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GOFAR MACHINERY

-

Dimension(L*W*H):

-

700*350*2200

-

Weight:

-

100 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Function:

-

FILLING MACHINE

-

Filling speed:

-

1200BPH

-

Filling head:

-

2--6

-

Product name:

-

quantitative filler Laundry Liquid filling machine

-

Keywords:

-

Liquid Filling machine

-

Advantage:

-

High Effiency

-

Feature:

-

High Precision Filling Level

-

Control:

-

PLC+ Touch Screen

♦This machine is an semi-automatic filling machine with 4 heads, the bottles are loadedand unloaded artificially.

♦ It used for the liquid like water; glass cleaner water; spirit; liqueur and so on

♦ It used for the liquid like water; glass cleaner water; spirit; liqueur and so on

|

Model

|

GFZL-4

|

|

Production capacity

|

1200

|

|

Filling principle

|

gravity filling

|

|

Filling standard

|

depends on customer

|

|

Bottle height

|

subject to the cap type provided by the customer

|

|

Power

|

0.37/0.55 (KW)

|

|

Dimensions

|

700*350*2200mm(subject to actual equipment)

|

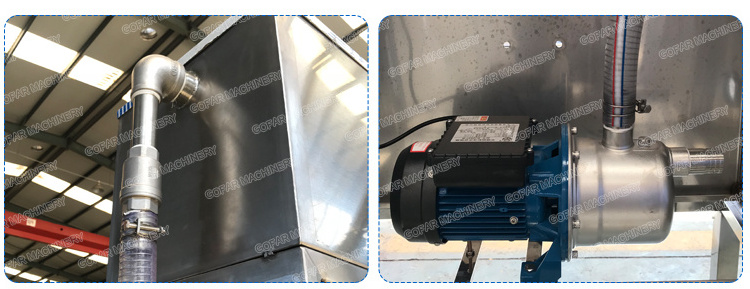

♦ It makes from SUS304

♦ The operation interface is easy and humanized

♦ The filling head is suit for the standard of the bottle ,and it can be changed easily

♦ The pump will add liquid to feed box when level under the floater and stop to convery liquid when it hold the level with floater timely

♦ The operation interface is easy and humanized

♦ The filling head is suit for the standard of the bottle ,and it can be changed easily

♦ The pump will add liquid to feed box when level under the floater and stop to convery liquid when it hold the level with floater timely

Recommend Products

Qingzhou Gofar Packaging Machinery Co.,Ltd is a professional manufacturer of liquid packing solutions with 10 years experiences. We specialized in wine filling production line, spirit filling production line,detergent production line,sauce filling production line, oil filling production line,water treatment etc. The most of our products have passed the ISO9001 and CE certificated. And we also have professional technical team to provide the professional solution for you according to your requirements.

In recent years,our company has introduced series of advanced equipments, including laser cutting machine, CNC tapping machine and machining centers, to make the per part more precision. All the parts will be via checking and testing before assembly to guarantee the quality. All the machines will be tested and debugging again and again to make sure without problems. And the staff will have be trained regularly. We bring in technicians per year. The timely after-sale service,spare parts support and technical support will be provided at anytime. With professional team,hope we will bring you the excellent service and satisfaction.

Our machine is mainly made of good quality SUS304 stainless steel and equipped with brand parts. It has the advantage of easy operation,positioned accuracy, reasonable price etc. It's widely used in wineries,beverage,brewing,food, medicine, cosmetics, electronics, chemical pharmaceutical factories etc. With excellent quality and good reputation, we have exported to Europe, North America, South America, the Middle East, Southeast Asia, Africa more than 40 countries. We are sincerely looking forward to cooperate with you. Welcome to visit our factory.

Our Advantages

01 POWERFUL FACTORY

10 Years Manufacturing Experiences & 8 Years Exporting Experiences, not reseller, not tradingcompany.

02 ODM&OEM

Customized solutions are supported.

03 PROFESSIONAL TEAM AND SUPERIOR SERVICEH

Have an professional team and the staff will have be trained regularly.

04 REASONABLE PRICE

Easy operation, positioned accuracy, reasonable price.

05 QUALITY ASSURANCE

Improve your working efficiency and help you resolved the problem of difficult employment and high labor costs.

06 ONLINE INSTRUCTION

Online conferences product explanation, technical guidance, factory inspection etc are supported.

07 AFTER-SALES SERVICE

The job site installation, training, guidance are supported. The staff will have be trained regularly.

02 ODM&OEM

Customized solutions are supported.

03 PROFESSIONAL TEAM AND SUPERIOR SERVICEH

Have an professional team and the staff will have be trained regularly.

04 REASONABLE PRICE

Easy operation, positioned accuracy, reasonable price.

05 QUALITY ASSURANCE

Improve your working efficiency and help you resolved the problem of difficult employment and high labor costs.

06 ONLINE INSTRUCTION

Online conferences product explanation, technical guidance, factory inspection etc are supported.

07 AFTER-SALES SERVICE

The job site installation, training, guidance are supported. The staff will have be trained regularly.

Certifications

We have passed :sealing machine CE certification, filling machine CE certification, ISO9001,SGS and other certification, to ensure the quality of products.

Exhibition

Packing &Shipping

1.Packing:

The finished well machines products immediately outside the anti-rust treatment,

and the use of plastic packaging for further protection, delivery using thick wood, steel frame protection,and other diversified packaging conditions to ensure that products in the long sea is not affected.

2. Delivery time:

Even though our machines are customzied as bottles size and shape, our plant also will reserve some parts on warehouse,such as electronic parts,frame,pump,SUS materials etc to shorten the delivery time.

3. Shipping:

The normally used is by sea. If you are urgent, we can ship by air or express. In short, we will choose an economic shipping way for you.

4. Port:

Qingdao, Shanghai etc,if you have forwarder in China,we can transport the washing machine to him directly.

Service

1. Technical Support:

* Professional engineers are available during the project design.

* Detailed equipment drawing design to show you exact required oilfilling production line.

* Make the equipment design with Auto cad, Solid work 3D for the equipment details and layout drawing.

* Support project expansion design in the future.

2. Professional After-Sales Service Team is Available

* The equipments testing and debuggingoperation in Gofar workshop, offer you the video and picture.

* Offer all the required spare parts based on the layout drawing.

* Mark all the pipelines and valves with numbers, take pictures and videos to make buy side installation easier.

* Give installation instruction from video and manual.

* After-sales service engineer can also go abroad for the installation, debugging and training. All the travelling cost and local food and hotel shall be afforded by the buyer.

3. Our After-sale Service

* Assist purchase facilities including bottling system, steam boiler, water treatment, etc.

* Free consultation service before, during, and after sales.

* Manage equipments' long distance shipping from seller's factory to buyer’s sea port or location.

* Remind of regular maintenance.

FAQ

Q1.How long will take for the delivery of product?

10 days for standard model, if machine in stock, will delivery immediately, customized model depend on customer requirements,usually about 20~30 days.

Q2

.

What's the insurance of after-sale service after purchase?

All our products, will be totally tested by QC department before delivery, with strict quality control process. The product is cost-effective during use, stable and reliable. One year warranty service for all machine, please feel free to contact us if you have any questions.

Q3.When the machine arrives at the work site, is it easy to install?

How to solve the problem of quick installation and use?

All machine model with installation video, to show the installation process more intuitively, and we will provide remote video technical support to solve your doubts and ensure that your installation is correct.

Q4:During the use of the machine, how to get after-sale service?

We have professional foreign installation and commissioning engineers, which have many years of experience in foreign debugging with deeply recognized by customers. We will provide on-site installation and commissioning services for foreign customers, and we will guide your workers directly.

Q5:Will the accessories change frequently with machine?

The service life of the accessories is related to the daily maintenance. When ordering, we will give you free wearing parts and provide you with daily maintenance strategies.

Hot Searches