- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

185 - 490 mm

-

Ejector Stroke(mm):

-

100 mm

-

Ejector Force(kN):

-

42 kN

-

Theoretical Shot Volume(cm³):

-

344 cm³

-

Injection Rate (g/s):

-

160 g/s

-

Injection Weight (g):

-

313 g

-

Screw Speed (rpm):

-

1 - 210 rpm

-

Screw diameter (mm):

-

40 mm

-

Screw L/D Ratio:

-

21

-

Weight (KG):

-

4000

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

446 mm

-

Model Number:

-

GM2-LS160S

-

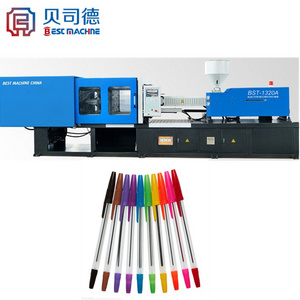

Brand Name:

-

LANSON

-

Power (kW):

-

16 kW

-

Product name:

-

LANSON GM2-LS160S plastic injection moulding machine

-

Keyword:

-

ball pen making machine injection moulding machine

-

Function:

-

precision, fast response, high efficiency and energy saving

-

Prices:

-

Negotiable

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

Clamping Force (kN):

-

1600

-

Certification:

-

CE ISO9001

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

460 mm

-

Distance between Tie Bars(Height)(mm):

-

460 mm

-

Plasticizing Capacity(g/s):

-

24.6

-

Mold Height(mm):

-

185 - 490 mm

-

Ejector Stroke(mm):

-

100 mm

-

Ejector Force(kN):

-

42 kN

-

Theoretical Shot Volume(cm³):

-

344 cm³

-

Injection Rate (g/s):

-

160 g/s

-

Injection Weight (g):

-

313 g

-

Screw Speed (rpm):

-

1 - 210 rpm

-

Screw diameter (mm):

-

40 mm

-

Screw L/D Ratio:

-

21

-

Weight (KG):

-

4000

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

446 mm

-

Model Number:

-

GM2-LS160S

-

Brand Name:

-

LANSON

-

Power (kW):

-

16 kW

-

Product name:

-

LANSON GM2-LS160S plastic injection moulding machine

-

Keyword:

-

ball pen making machine injection moulding machine

-

Function:

-

precision, fast response, high efficiency and energy saving

-

Prices:

-

Negotiable

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

Clamping Force (kN):

-

1600

-

Certification:

-

CE ISO9001

Products Description

GM2-S designed for high variety, high end plastic products with traditional twin-cylinder injection unit. Tonnage ranges from 900KN to 5600KN.

Manufacturing Technique

Toshiba TOSNUC 999 Milling Machine

6 sets of this kind high-end machines to make sure platen, toggle, circuit board, cylinder components unit under high precision CNC machining, persuing the machine high precision performance.

Parkson UBM-11020RS CNC machine

10 sets of this kind advance equipment to strictly control components precision and longer service life, to make sure Lanson injection molding machine precision beyond the industry level.

Doosan Duma 280M Lathe machine

Over 40 sets imported machining equipments to maintain frame, sheet metal, parts processing surface spraying forming complete independent supply capacity.

Installation Instructions

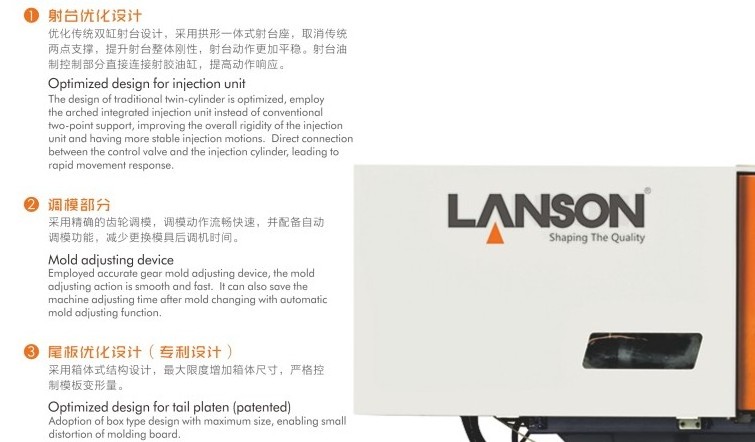

Injection System Features

1. optimized double cylinder injection

2. Injection unit guide rod

3. complete casting base instead of two point support with higher rigidity

4. Optional screw and barrel

Clamping System Features

1. High rigidity high strength

2. Accurate and timesaving gear mold adjusting device

3. Widened toggle with long service life

4. Centralizing electric lubrication

Control System Features

1. diversification professional control system

2. equip with servo control system

3. famous brand hydraulic component

4. precision hydraulic filter element

Product Paramenters

|

Model

|

|

GM2-LS160S

|

|

|

||

|

International Size Desciption

|

|

1600-571

|

|

|

||

|

Injection Unit

|

|

|

|

|

||

|

Screw No.

|

|

A

|

B

|

C

|

||

|

Screw Diameter

|

mm

|

40

|

45

|

50

|

||

|

Screw Ratio

|

L/D

|

23.5

|

20.9

|

18.8

|

||

|

Shot Volume

|

cm3

|

271

|

344

|

424

|

||

|

Shot Weight(PS)

|

g

|

247

|

313

|

386

|

||

|

Plasticizing Capacity(PS)

|

g/s

|

18.4

|

27.6

|

34

|

||

|

Injection Pressure

|

Mpa

|

211

|

166

|

135

|

||

|

Screw Speed

|

rpm

|

210

|

|

|

||

|

Clamping Unit

|

|

|

|

|

||

|

Clamping Force

|

KN

|

1600

|

|

|

||

|

Mould Opening Stroke

|

mm

|

446

|

|

|

||

|

Space between Tie Bar

|

mm

|

460X460

|

|

|

||

|

Platen Size

|

mm

|

690X690

|

|

|

||

|

Max. Mold Height

|

mm

|

185

|

|

|

||

|

Min. Mold Height

|

mm

|

490

|

|

|

||

|

Ejector Stroke

|

mm

|

130

|

|

|

||

|

Ejector Force

|

KN

|

42

|

|

|

||

|

Ejector Number

|

PC

|

5

|

|

|

||

|

Other

|

|

|

|

|

||

|

Hydraulic Pressure

|

MPa

|

17.5

|

|

|

||

|

Pump Motor Power

|

KW

|

16

|

|

|

||

|

Heater Power

|

KW

|

10

|

|

|

||

|

Oil Tank Capacity

|

L

|

345

|

|

|

||

|

Machine Dimension(LxWxH)

|

m

|

5.1X1.27X1.95

|

|

|

||

|

Machine Weight

|

ton

|

4

|

|

|

||

Applications

Recommend Products

Product packaging

Certifications

Hot Searches