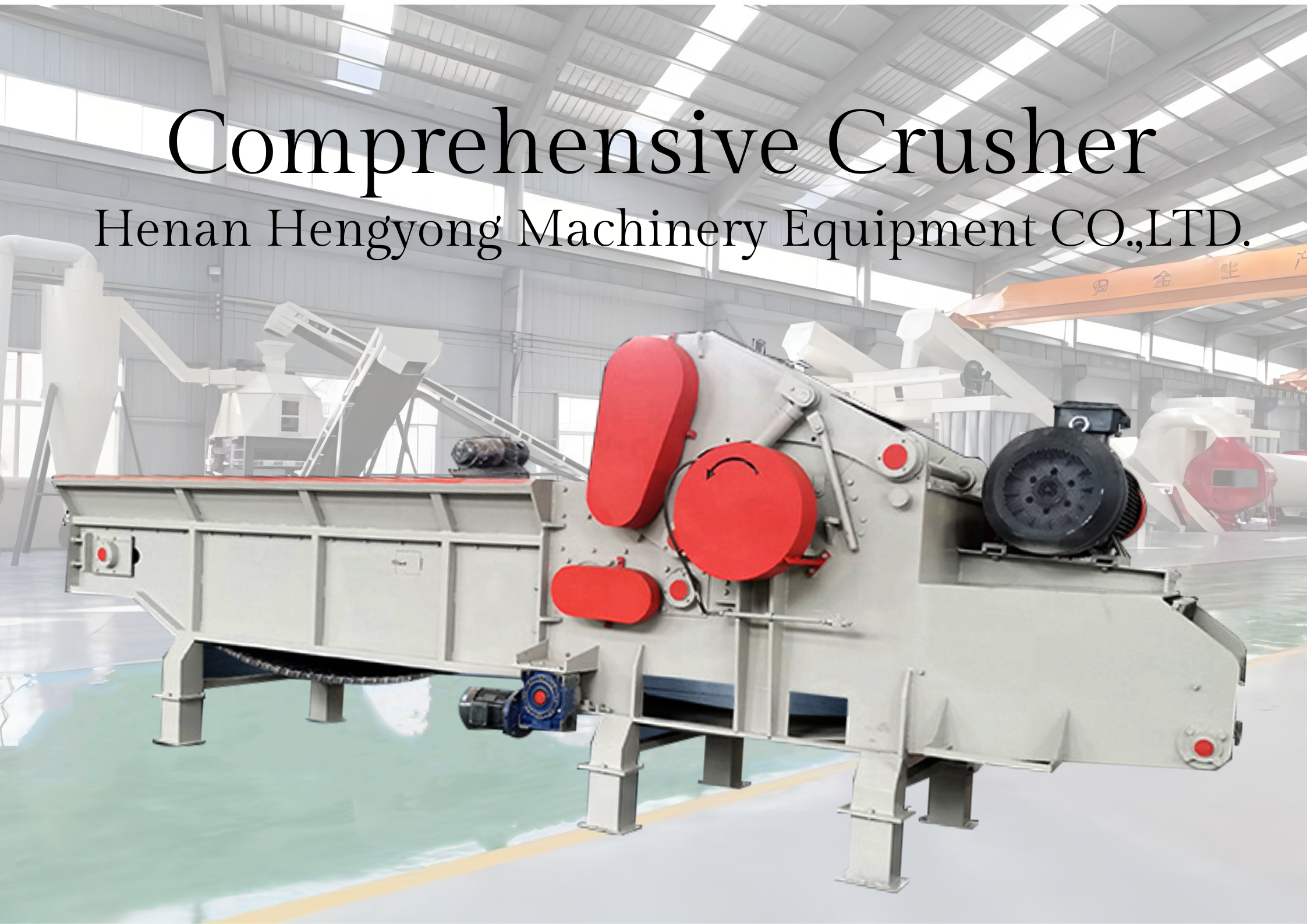

The comprehensive wood crusher is suitable for waste packaging boxes, templates, plates branches,wooden crates,pallets and other materials.

Including Host, Chain Plate, feeding and outlet system,intelligent electrical control.

The Comprehensive crusher has reasonable structure,simple operation, high automatic level, high safety coefficient and production capacity, less manpower, easy maintenance.

It is the ideal equipment for biomass power generation enterprises.