- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

jiujin

-

Model Number:

-

SY295 SY390 Q345B, SY295, SX27,SKSP-SX10,SKSP-SX18

-

Surface treatment:

-

Black

-

Shape:

-

U/Z

-

Technique:

-

Hot Rolled and Cold Rolled

-

Supply capacity:

-

6000tons/month

-

Main market:

-

Middle

-

Usage:

-

Construct Seawalls

-

Length:

-

6m / 12m or customization

Quick Details

-

Grade:

-

GB,JIS,EN standard

-

Standard:

-

AiSi

-

Tolerance:

-

±1%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

jiujin

-

Model Number:

-

SY295 SY390 Q345B, SY295, SX27,SKSP-SX10,SKSP-SX18

-

Surface treatment:

-

Black

-

Shape:

-

U/Z

-

Technique:

-

Hot Rolled and Cold Rolled

-

Supply capacity:

-

6000tons/month

-

Main market:

-

Middle

-

Usage:

-

Construct Seawalls

-

Length:

-

6m / 12m or customization

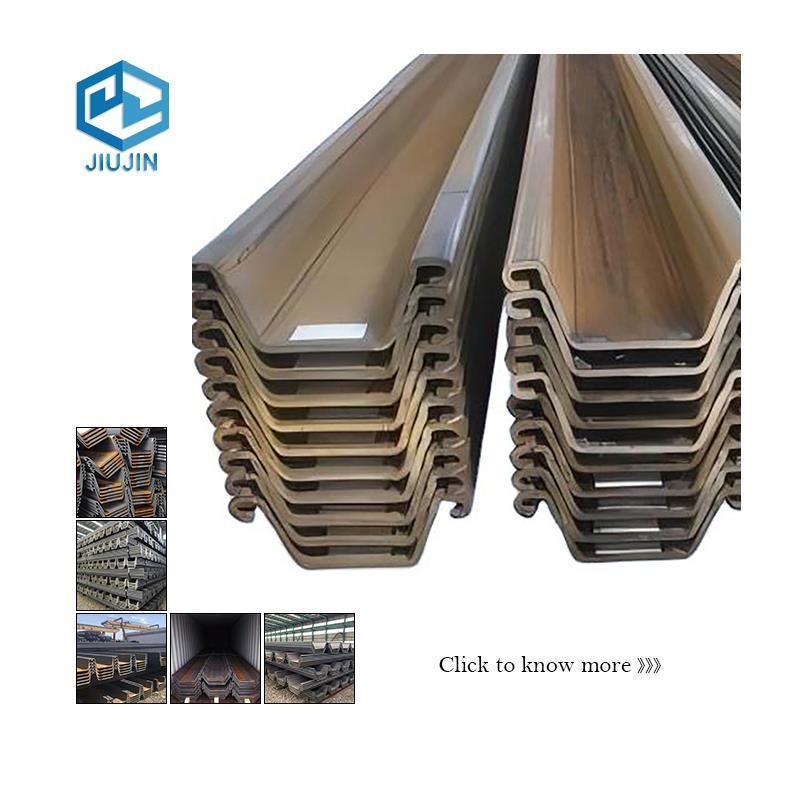

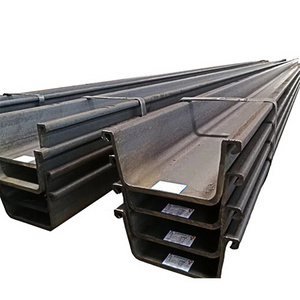

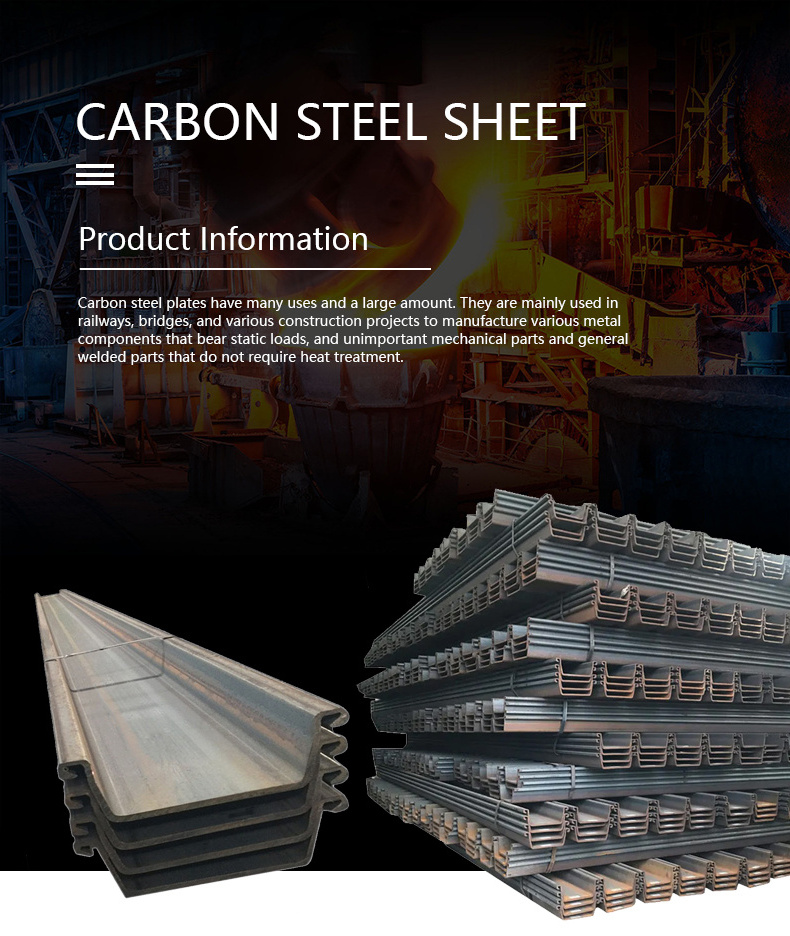

Products Description

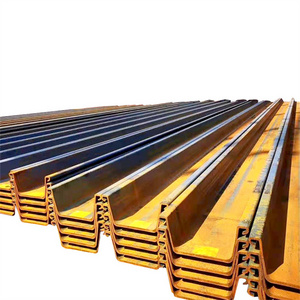

Q235 Q355 SY295 SY390 cold forming hot rolled steel sheet pile z sheet pile SX27 Our steel sheet pile features high strength, light weight, good water-resisting performance and super durability.Hot rolled steel sheet pile is a kind of high efficient energy saving building materials.Widely used in embankment, a loadingdock, dock, temporary Island, dyke, Luqiao, temporary pier revetment revetment, waterproof cofferdam, river, embankment reinforcement, retaining wall, retaining wall and the construction foundation pit bracing structure of foundation engineering

Description :

Applications:

Steel sheet piles are a type of prefabricated structural element made of steel. They are widely used in construction, civil engineering, and waterfront structures for their excellent structural performance and versatility. Here is a detailed description of steel sheet piles, including their characteristics, applications, production process, material specifications, and classification.

Description :

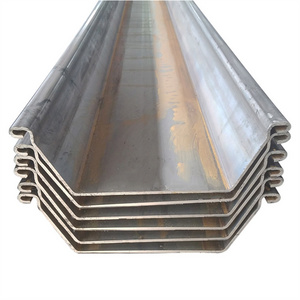

Steel sheet piles are long, thin sections of steel that are interlocked together to create a continuous wall. They are typically installed in the ground to provide lateral support and retain soil or water. Steel sheet piles are available in various shapes, such as U-shaped, Z-shaped, or straight plates with interlocking edges. These interlocks allow the individual sheets to be connected together to form a watertight wall.

Applications:

Steel sheet piles have numerous applications in construction and civil engineering projects:

1. Retaining walls: Steel sheet piles are commonly used in the construction of retaining walls to prevent soil erosion and provide stability. They can withstand high loads and soil pressures, making them an ideal choice for retaining earth or water.

2. Cofferdams: Steel sheet piles are frequently used for cofferdam construction in marine works or bridge pier foundations. They create a temporary barrier to enable construction in dry conditions and protect workers from water infiltration.

3. Flood protection: Steel sheet piles are employed in flood control systems to create flood walls and levees. They help to contain and redirect water during flood events, protecting surrounding areas from inundation.

4. Deep excavation: Steel sheet piles are often used to support deep excavations, such as basements or underground structures.They provide temporary or permanent support and prevent soil collapse.

5. Marine structures: Steel sheet piles are commonly used in the construction of quay walls, breakwaters, jetties, and seawalls.They offer excellent resistance to water and wave forces, providing stability and protection against erosion.

Production Process:

1. Retaining walls: Steel sheet piles are commonly used in the construction of retaining walls to prevent soil erosion and provide stability. They can withstand high loads and soil pressures, making them an ideal choice for retaining earth or water.

2. Cofferdams: Steel sheet piles are frequently used for cofferdam construction in marine works or bridge pier foundations. They create a temporary barrier to enable construction in dry conditions and protect workers from water infiltration.

3. Flood protection: Steel sheet piles are employed in flood control systems to create flood walls and levees. They help to contain and redirect water during flood events, protecting surrounding areas from inundation.

4. Deep excavation: Steel sheet piles are often used to support deep excavations, such as basements or underground structures.They provide temporary or permanent support and prevent soil collapse.

5. Marine structures: Steel sheet piles are commonly used in the construction of quay walls, breakwaters, jetties, and seawalls.They offer excellent resistance to water and wave forces, providing stability and protection against erosion.

Production Process:

The production process of steel sheet piles involves the following steps:

1. Material selection: High-quality steel, typically with a minimum yield strength of 355 MPa, is selected for manufacturing sheet piles. The steel should possess good weldability and toughness to withstand construction loads.

2. Rolling: The selected steel is rolled into the desired shape using hot rolling or cold forming methods. Hot rolling involves passing the steel through a series of rollers at high temperatures, while cold forming uses press brakes to bend the steel.

3. Interlocking process: The interlocking edges of the sheet piles are formed by profiling or cold-forming techniques. This process creates the necessary locks that allow individual piles to be interconnected.

4. Surface treatment: Steel sheet piles are often coated with protective layers to enhance their durability and corrosion resistance. Common surface treatments include galvanizing, painting, or applying epoxy coatings.

Material Specifications:

1. Material selection: High-quality steel, typically with a minimum yield strength of 355 MPa, is selected for manufacturing sheet piles. The steel should possess good weldability and toughness to withstand construction loads.

2. Rolling: The selected steel is rolled into the desired shape using hot rolling or cold forming methods. Hot rolling involves passing the steel through a series of rollers at high temperatures, while cold forming uses press brakes to bend the steel.

3. Interlocking process: The interlocking edges of the sheet piles are formed by profiling or cold-forming techniques. This process creates the necessary locks that allow individual piles to be interconnected.

4. Surface treatment: Steel sheet piles are often coated with protective layers to enhance their durability and corrosion resistance. Common surface treatments include galvanizing, painting, or applying epoxy coatings.

Material Specifications:

Steel sheet piles are typically made from structural-grade steels, which are known for their high strength and excellent weldability. The most commonly used steel grades for sheet piles include:

1. ASTM A572: This grade offers high strength and impact resistance, making it suitable for demanding applications.

2. ASTM A690: This grade provides excellent corrosion resistance and is commonly used in marine environments or areas with high soil acidity.

3. EN 10248: European standard for hot-rolled sheet piles, which specifies the mechanical properties and dimensions of various steel grades.

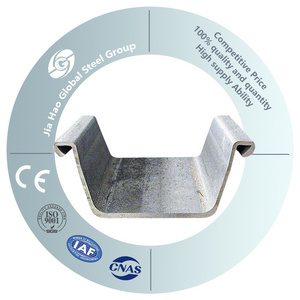

Classification: Steel sheet piles can be classified based on their shapes, interlocking systems, and manufacturing methods:

1. Shape classification: Steel sheet piles can have U-shaped (U), Z-shaped (Z), or straight (flat) shapes. Each shape has its advantages and is selected based on specific project requirements.

2. Interlocking system: Steel sheet piles can have different types of interlocks, such as Larssen interlocks or hook interlocks.The interlock design determines the connection strength, water tightness, and ease of installation.

3. Manufacturing method: Steel sheet piles can be produced by hot rolling or cold forming processes. Hot-rolled sheet piles are manufactured by heating and rolling steel, while cold-formed sheet piles are made by bending flat steel plates using press brakes.

In conclusion, steel sheet piles are versatile structural elements widely used in construction and civil engineering projects .They are used for retaining walls, cofferdams, flood protection, deep excavations, and marine structures. The production process involves material selection, rolling, interlocking, and surface treatment. Steel sheet piles are typically made from high-strength steels and can be classified based on their shape, interlocking system, and manufacturing method.

1. ASTM A572: This grade offers high strength and impact resistance, making it suitable for demanding applications.

2. ASTM A690: This grade provides excellent corrosion resistance and is commonly used in marine environments or areas with high soil acidity.

3. EN 10248: European standard for hot-rolled sheet piles, which specifies the mechanical properties and dimensions of various steel grades.

Classification: Steel sheet piles can be classified based on their shapes, interlocking systems, and manufacturing methods:

1. Shape classification: Steel sheet piles can have U-shaped (U), Z-shaped (Z), or straight (flat) shapes. Each shape has its advantages and is selected based on specific project requirements.

2. Interlocking system: Steel sheet piles can have different types of interlocks, such as Larssen interlocks or hook interlocks.The interlock design determines the connection strength, water tightness, and ease of installation.

3. Manufacturing method: Steel sheet piles can be produced by hot rolling or cold forming processes. Hot-rolled sheet piles are manufactured by heating and rolling steel, while cold-formed sheet piles are made by bending flat steel plates using press brakes.

In conclusion, steel sheet piles are versatile structural elements widely used in construction and civil engineering projects .They are used for retaining walls, cofferdams, flood protection, deep excavations, and marine structures. The production process involves material selection, rolling, interlocking, and surface treatment. Steel sheet piles are typically made from high-strength steels and can be classified based on their shape, interlocking system, and manufacturing method.

|

Steel Grade

|

S275,S355,S390,S430,SY295,SY390,ASTM A690

|

|

Production standard

|

EN10248,EN10249,JIS5528,JIS5523,ASTM

|

|

Delivery time

|

One week,80000 tons in stock

|

|

Certificates

|

ISO9001,ISO14001,ISO18001,CE FPC

|

|

Dimensions

|

Any dimensions,any width x height x thickness

|

|

Interlock types

|

Larssen locks,cold rolled interlock,hot rolled interlock

|

|

Length

|

Single length up to over 80m

|

|

Technique

|

Hot Rolled Cold Rolled

|

|

Standard

|

AiSi

|

|

Processing Service

|

Punching, Cutting

|

|

Tolerance

|

±1%

|

|

Alloy Or Not

|

Non-Alloy

|

Details Images

Hot Searches