- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HENER

-

Voltage:

-

380V 60Hz

-

Dimension(L*W*H):

-

7700*1500*1700mm

-

Weight:

-

5000 kg

-

Marketing Type:

-

Hot Product 2024

-

Machine Frame:

-

350mm H Beam Structure, With 18 mm Welded Steel Middle Support Plate

-

Material Of Rollers:

-

High Grade 45# Forged Steel Chromed Treatment

-

Forming Stations Roller Stations:

-

18 Rows

-

Transmission Way:

-

By 1 Inch Chain (Double Chains)

-

Main Motor:

-

5.5+4 kw

-

Cutting Blade Material:

-

Gcr12 quenched treatment

-

Cutting Type:

-

hydraulic post cutting

-

Usage:

-

Roof Panel Sheets

-

Color:

-

Custimized

-

After-sales Service Provided:

-

3 Years

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HENER

-

Voltage:

-

380V 60Hz

-

Dimension(L*W*H):

-

7700*1500*1700mm

-

Weight:

-

5000 kg

-

Marketing Type:

-

Hot Product 2024

-

Machine Frame:

-

350mm H Beam Structure, With 18 mm Welded Steel Middle Support Plate

-

Material Of Rollers:

-

High Grade 45# Forged Steel Chromed Treatment

-

Forming Stations Roller Stations:

-

18 Rows

-

Transmission Way:

-

By 1 Inch Chain (Double Chains)

-

Main Motor:

-

5.5+4 kw

-

Cutting Blade Material:

-

Gcr12 quenched treatment

-

Cutting Type:

-

hydraulic post cutting

-

Usage:

-

Roof Panel Sheets

-

Color:

-

Custimized

-

After-sales Service Provided:

-

3 Years

China Automatic Corrugated Wave Roof Panel Roofing Sheet Roll Former Metal Roll Forming Machine Manufacturers

:

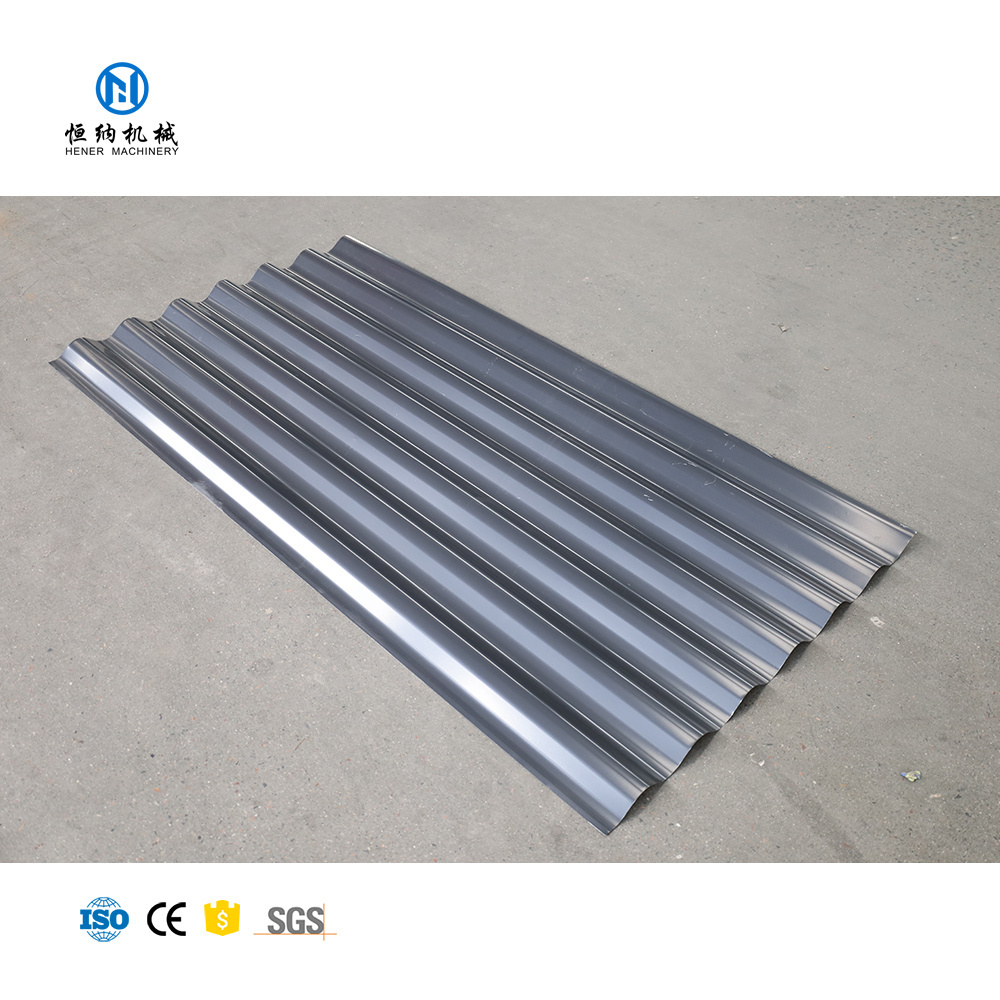

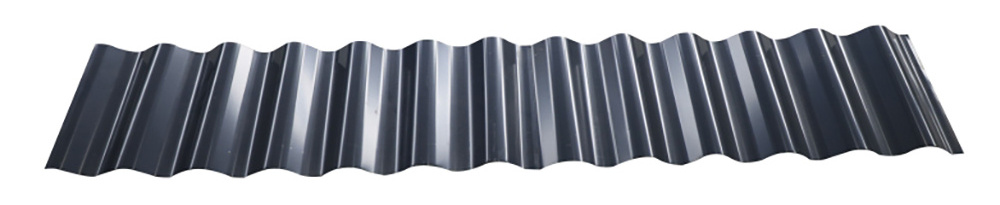

The corrugated roll forming machine is primarily used for producing corrugated metal sheets, which are commonly utilized for roofing and wall cladding, as well as covering agricultural and industrial facilities. These corrugated metal sheets boast excellent strength and durability, making them widely employed in various construction and engineering projects.

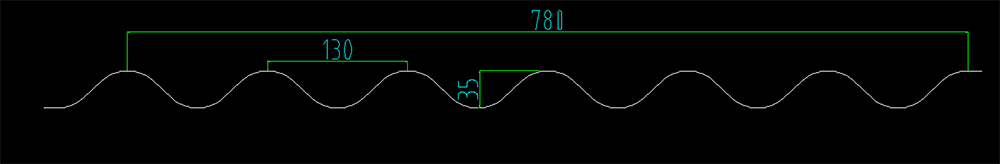

Profile drawing for reference:

Roofing sheet has many different shapes,usually different countries have its own popular design ,we can customize the machine as customers’ demand.

Processing Flow:

Decoiler-

Feeding material into machine -Roll forming - Hydraulic cutting -Products receiving table

|

China Automatic Corrugated Wave Roof Panel Roofing Sheet Roll Former Metal Roll Forming Machine Manufacturers

|

|

|

|

Raw Material

|

PPGI,GI

|

|

|

Material Thickness

|

0.3 - 0.8mm(31-21 Gauge)

|

|

|

Machine Frame

|

350mm H Beam Structure, With 18 mm Welded Steel Middle Support Plate.

|

|

|

Material Of Rollers

|

High Grade 45# Forged Steel. Chromed Treatment (Chrome Thickness:0.05 Mm), Make The Rollers Surface More Smoothly, Improve The Hardness And Prevent Abrasion,Anti Corrosion Increase Of Service Life

|

|

|

Diameter of shafts

|

Φ75mm

|

|

|

Material of shafts

|

45# Steel Thermal Refining, Prevent Deformed And Improve The Hardness

|

|

|

Forming speed

|

About 15m/min

|

|

|

Voltage

|

380v 50hz 3phase Or As local customer request

|

|

|

Work power

|

9.5 kw

|

|

|

Cutting type

|

Hydraulic cutting

|

|

|

Cutting blade material

|

Cr12Mov, with acutting lifespan exceeding 1 million times.

|

|

Feeding Device

1. There are 2 rollers at the feeding device, which can be rotated to reduce the friction of the feeding and avoid scratches on the surface of the material.

2.Touch stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

3. With a hand wheel to adjust the feeding width, making the feeding more accurate.

4. With broach, it is convenient to cut material

Roll Forming Device

1. Frame:350H steel

2. Roller stations:18+16 stations

3. Roller materila:45# steel with quenched treatment and hard chroming

4. Shaft material:45# steel with tempering treatment

5. Motor power:5.5kw

2. Roller stations:18+16 stations

3. Roller materila:45# steel with quenched treatment and hard chroming

4. Shaft material:45# steel with tempering treatment

5. Motor power:5.5kw

Our machine use very thick material to manufacturing the machine basic frame, ensure very stable when it running.

The machine especially add diagonal bracing to make sure stability.

Automatic Shearing System

1. Utilizing a dual oil cylinder system for enhanced stability over single cylinder setups.

2. Hydraulic motor rated at 5.5 kW, equipped with an energy accumulator.The cutter is constructed from GB-Cr12 material and undergoes heat treatment.

3. Cutting length tolerance is within ±10 meters per 2 millimeters.

4. Cutting operations are characterized by a stable and safe working environment, producing minimal noise.

PLC control system

1.

Structure: Cantilever-type

2.

Advantages: All wiring connections are completed, preventing wiring errors during installation that could otherwise affect the

normal operation of the machine.

normal operation of the machine.

3. Main components origin: PLC (

Delta

), relay (Schneider Electric, France), length encoder (OMRON),

Encoder: OMRON

.

4.

Operation language:English(it can also customized language for our customer)

Hydraulic station

The hydraulic oil station is outfitted with 2 solenoid valves and a robust 5.5 kW motor to accommodate the machine's

high-intensity operations. It requires the addition of 46# hydraulic oil. During filling, an oil gauge display is provided,

ensuring precise measurement even if the filling volume exceeds the gauge's scale.

high-intensity operations. It requires the addition of 46# hydraulic oil. During filling, an oil gauge display is provided,

ensuring precise measurement even if the filling volume exceeds the gauge's scale.

Q1. Can you manufacture the roll forming machine according to my profile drawing or picture of finished product ?

A: Yes. Our rich experienced technical team can draft the accurate profile drawing, provide the most suitable technical solution for your required roll forming machine.

Q2. How can we be assured that you will deliver us quality machine with spare parts ?

A: 1. Customers can come to our factory, or send the technical people to our factory for checking the quality.

2. We can send the technicians to the buyer's factory for the installation of the machine.

Q3. What's your payment terms and delivery time?

A: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 45 workdays for delivery.

Q4. Do you have after-sales support?

A: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q5. Do you sell only standard machines?

A: No, most of our machines are customized according to customers specifications, also adopt top brand components.

Q6. What will you do if the machine is broken?

A: We provide 1 year free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the roll forming machine.

Q7. Can you be responsible for transport?

A: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q8. How to visit your company?

A:1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2)Fly to Tianjin airport, By high speed train From Tianjin to Cangzhou Xi (0.5 hour).

3) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

Hot Searches