- Product Details

- {{item.text}}

Quick Details

-

After-sale service:

-

Lifelong

-

Flowchart design:

-

Available

-

CAD layout drawing:

-

Available

-

Installation:

-

Guided by our engineer or the layout drawing

-

Sample testing:

-

Available

-

Application:

-

Rock gold and alluvial gold recovery

-

Certification:

-

CE; SGS; ISO9001:2008

Quick Details

-

Place of Origin:

-

Jiangxi, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Feeding size:

-

Depends on your ore

-

After-sale service:

-

Lifelong

-

Flowchart design:

-

Available

-

CAD layout drawing:

-

Available

-

Installation:

-

Guided by our engineer or the layout drawing

-

Sample testing:

-

Available

-

Application:

-

Rock gold and alluvial gold recovery

-

Certification:

-

CE; SGS; ISO9001:2008

Gold Separating Machine And Gold Processing Plant

1.Description of rock gold processing line:

Generally speaking, the rock gold processing plant composes of many types of equipment, such as crusher, vibrating feeder, belt conveyor, ball mill, spiral classifier, vibrating screen, spiral separator, centrifugal concentrator, shaking table, flotation machine, gold meltng furnace, mercury amalgamator,etc .

Rock gold processing equipments is mainly depended on your actual situation and your expectation about the final product, such as the feeding size, the grade of the coarse ore and your expectation on the final product, etc.

2.Advantages of rock gold processing line:

- All products are manufactured with the guidance of ISO9001

- Each quality product to optimize the complete line, so it's more effective

- The gold recovery plant is low noise

- Whole life sale service for the ore mining equipment, so our client can rest assured

- Any spare parts is available in our factory

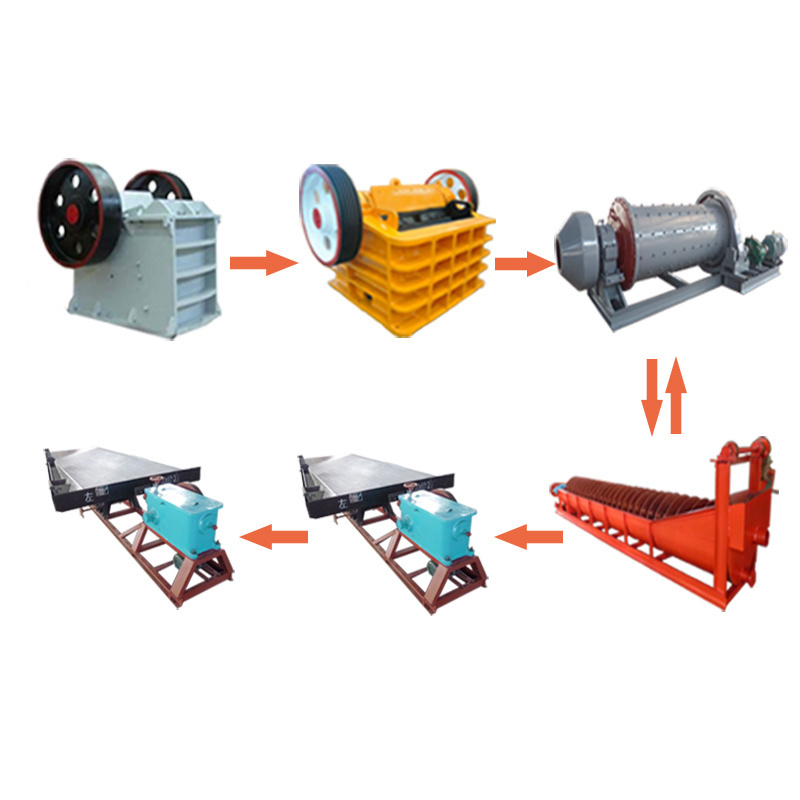

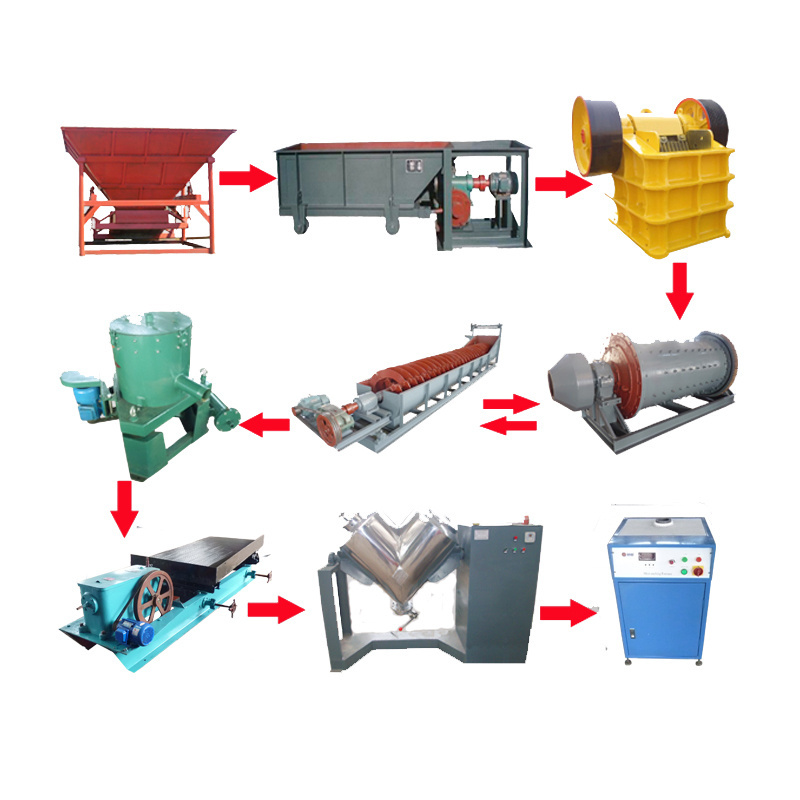

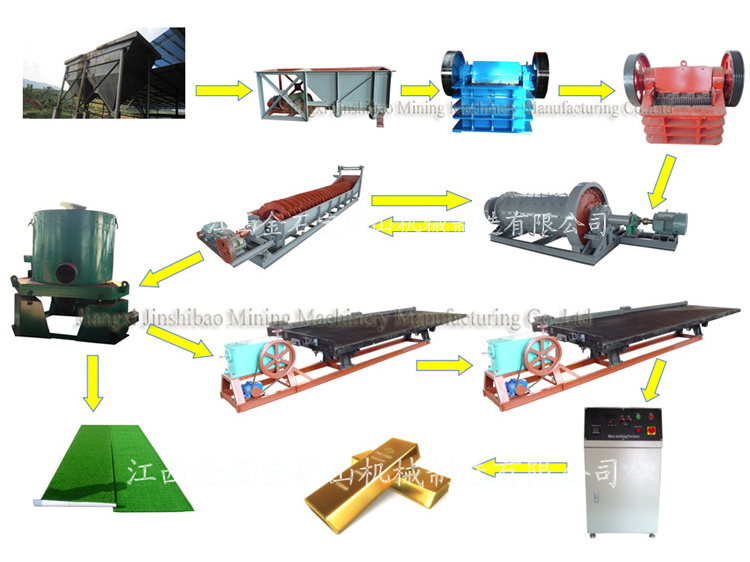

3.Procedures of rock gold processing line:

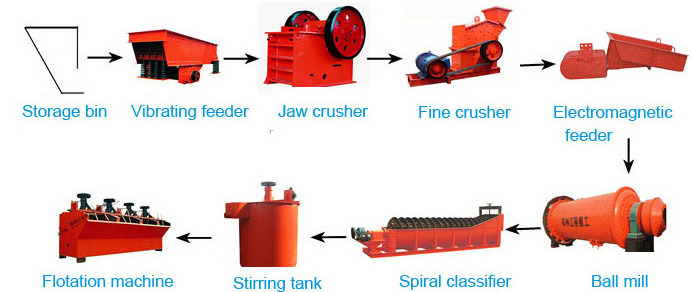

1). Flotation processing for rock gold processing line

a). Crushing and grinding stage

The raw ore need to be primarily crushed by jaw crusher, and then further crushed by fine crusher.

After getting the reasonable fineness, it is delivered into the ball mill by belt conveyor and feeder, then be grinded by ball mill.

b).Classifying stage

The spiral classifier and ball mill usually work in a close circle. the grinded ore will be delivered into spiral classifier.

When the spiral classifier is working, the relatively bigger sizes will be returned back to ball mill for regrinding;

While the relatively finer sizes will be overflowed to the next stage for separation.

c). Mixing and flotation stage

The classified ore with chemical agent gets into mixing tank for fully mixing. After fully mixing, the slurry will enter into flotation machine.

When the floatation machine works, the mineral is bounded with foams, and floats up to the surface of mineral slurry and the mineralized foam is formed.

The liquid surface can be adjusted with the height of adjustment flashboard, so that the useful foams are scraped with squeegee.

d).Gold recovery stage

After the flotation process, we can use the shaking table to elaborately select the concentrates.

Then concentrates with mercury to amalgamating and enter into melting furnace for gold bullion.

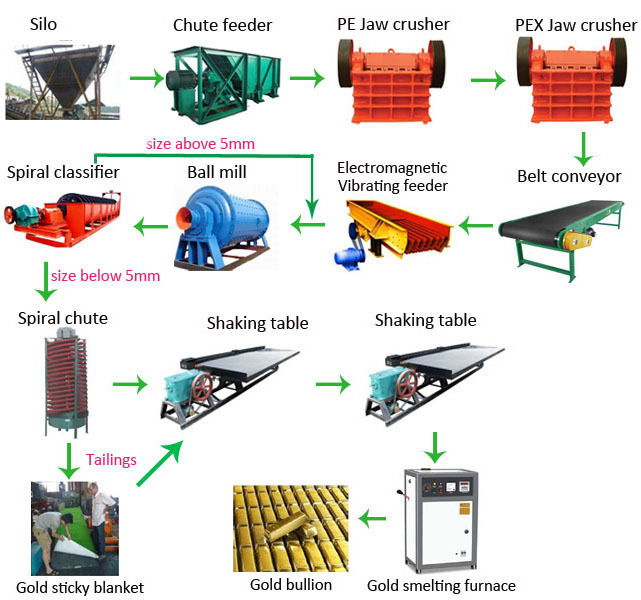

2). Gravity separation process for rock gold processing line

a). Crushing and grinding stage:

Same as flotation processing part

b). Classifying stage:

Same as flotation processing part

c). Gravity separation stage

In this stage, We use gold centrifugal concentrator or spiral separator to recover most of the useful minerals in the gold ore firstly .

Secondly, use the shaking tables for primary concentration.

Thirdly, also use shaking tables for concentrate cleaning.

d)Melting stage

After getting the concentrates, use mercury amalgamator and melting furnace to get the gold bullion.

Remark: Above processing line is just for your reference, we will design the flowchart based on our actual ore condition.

4. Mail product pictures related to rock gold processing line

3)Classifying (spiral classifier)

4) Flotation

5)Gravity separation ( centrifugal concentrator and shaking table )

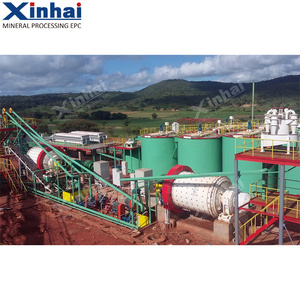

5.Application of rock gold processing line

6.Shipment of rock gold processing plant:

7. Trade terms of rock gold processing line:

|

Packing details |

Usually paid by T/T or L/C |

| By T/T 30% deposit and balance before shipment. | |

| We will send the goods picture to you once commodity ready. | |

| Packing details | By LCL or FCL(20'/40'GP) container. |

| LCL with steel support seaworthy packing | |

| Export software scientifical loading work | |

| Shipment details | Sea and air shipment available |

| MSK / MSC/ APL/ EMC/ WANHAI /KLINE | |

|

We will send the shipping notice to you once goods loading.

|