- Product Details

- {{item.text}}

Quick Details

-

Printing Type:

-

All kinds of printing machine

-

Weight (KG):

-

3

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

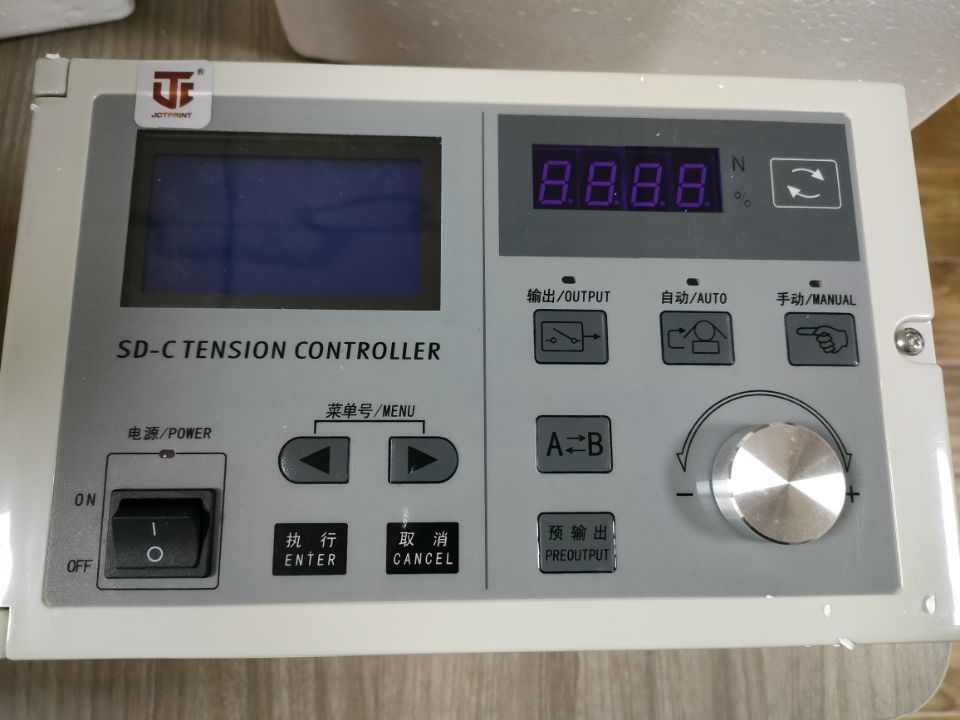

JCT

-

Product name:

-

High quality tension control magnetic powder brake

-

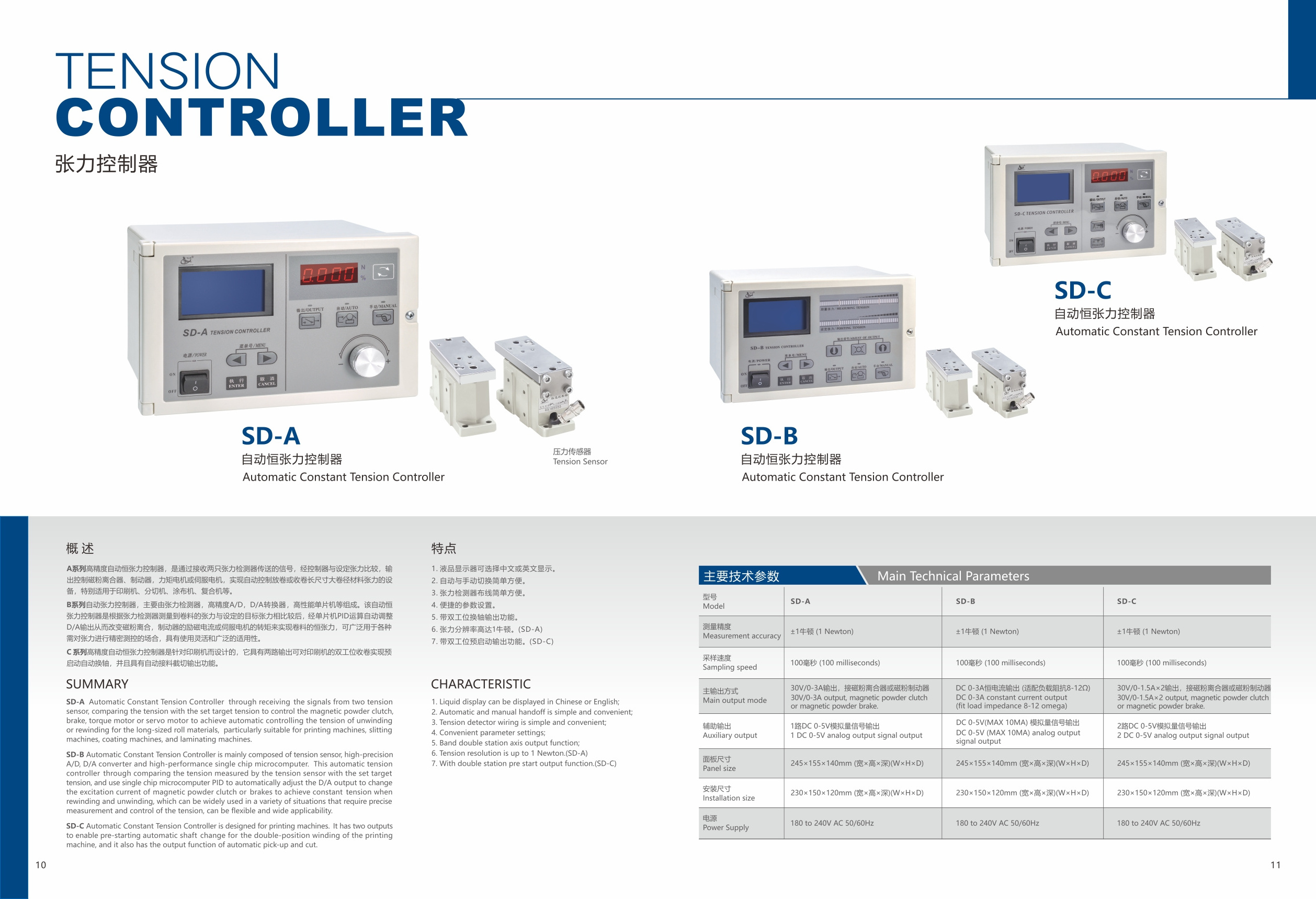

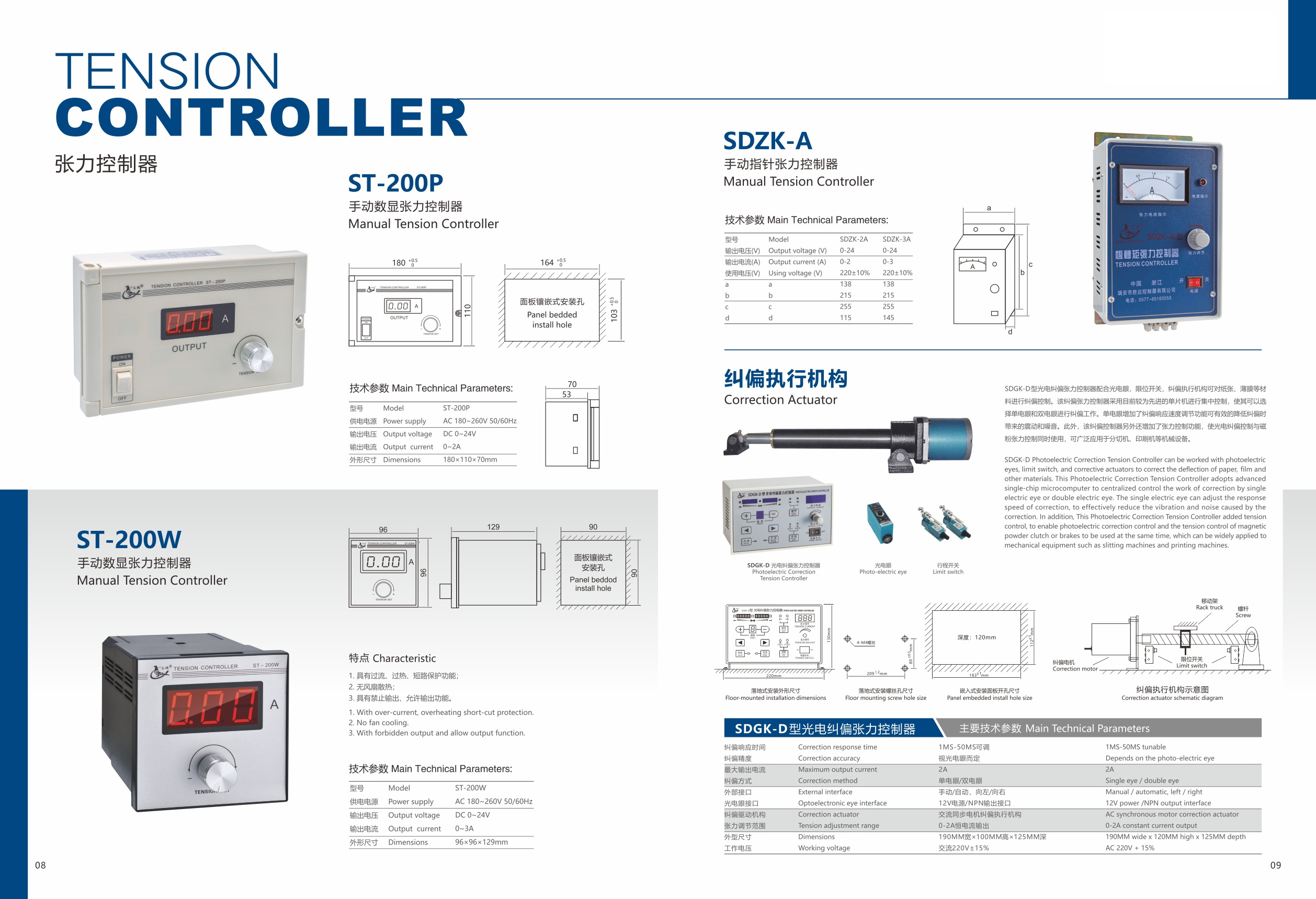

Model:

-

SD-A/B/D

-

Torque:

-

6-400 N.m

-

Voltage:

-

0-24V

-

Installation:

-

floor-mounted,wall-mounted,panel-mounted

-

output current:

-

0-4A

-

power supply voltage:

-

AC220V 50HZ

-

Control method:

-

Full Auto

-

Display mode:

-

liquid crystal display

-

Payment Term:

-

T\T

Quick Details

-

Condition:

-

New

-

Type:

-

Magnetic powder brake

-

Use:

-

All kinds of brand printing machine

-

Printing Type:

-

All kinds of printing machine

-

Weight (KG):

-

3

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JCT

-

Product name:

-

High quality tension control magnetic powder brake

-

Model:

-

SD-A/B/D

-

Torque:

-

6-400 N.m

-

Voltage:

-

0-24V

-

Installation:

-

floor-mounted,wall-mounted,panel-mounted

-

output current:

-

0-4A

-

power supply voltage:

-

AC220V 50HZ

-

Control method:

-

Full Auto

-

Display mode:

-

liquid crystal display

-

Payment Term:

-

T\T

Introduction

Automatic tension controller is mainly made up of tension detector, high accuracy A/D, D/A converter and microcomputer of high performance…etc. It realizes permanent tension of roll materials according to compare the tension of roll material measured by tension detector with the goal tension of settlement first, then through microcomputer PID operation and adjusting D/A output to change excitation electric current of magnetic powder clutch/ brake or torque of servomotor automatically. The controller can be used in several occasions needed to carry on measuring and controlling accurately with the tension and have application extensively with flexible in usage.

Features

1. Automatic unwind tension system deploys material tension detection roller.

2. The device will support auto-stop operation when material tension reaches the upper and lower limitation.

3. Unwinder device deploys automatic compensation tension control device.

4. The rotation speed then pre-set tension maintain by the roller when printing material rotate through the printing machine, no matter what the size, width, material.

5. Tension sensors roller monitor the roller tension of the material and amend any changes of the tension.