- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

2 years

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

Ansen

-

Model Number:

-

pr003

-

Product name:

-

wrap tape

-

Material:

-

Polyethylene

-

Type:

-

Bandage

-

MOQ:

-

10000pcs

-

Size:

-

20mm-110mm

-

Packing:

-

Plastic Bag+Carton

-

OEM:

-

Avaiable

-

Application:

-

Water Pipe System

-

Surface:

-

Paint Spraying

Quick Details

-

Technics:

-

Casting

-

Shape:

-

Equal

-

Head Code:

-

Square

-

Warranty:

-

2 years

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

Ansen

-

Model Number:

-

pr003

-

Product name:

-

wrap tape

-

Material:

-

Polyethylene

-

Type:

-

Bandage

-

MOQ:

-

10000pcs

-

Size:

-

20mm-110mm

-

Packing:

-

Plastic Bag+Carton

-

OEM:

-

Avaiable

-

Application:

-

Water Pipe System

-

Surface:

-

Paint Spraying

Ansen Pipe Repair

1. Introduction

A successful pipe repair can

be achieved in only 30 minutes

Ansen Leak Repair products enable any user to make a permanent repair to a burst or leaking pipe in under 30 minutes without formal training.Repairs are effective on pipes of all types in industrial and domestic settings and cost a fraction of carrying out a pipe replacement.

Epoxy putty offers a quick and easy solution for creating watertight seals around leaking faucets and filling and reparing cracks and holes in a pipe

2. Compared to National Brand RAPPIT

|

Name

|

Ansen

|

|

RAPPIT

|

|

||

|

Bandage Size

|

50mm x 3.6m, 50mm x 2.7m, 50mm x4.5 m,

75 mm x 3.6m , 75mm x2.7 m, 75mm x 4.5 m ,

100mm x 3.6m,100mm x 2.7 m, 100mm x4.5m,

125mm x3.6m,125mm x 2.7 m,125 mm x 4.5m,

150mm x3.6m, 150mm x 2.7m ,150mm x 4.5m

Bandage 's length can be made as your request. Max Length : 15 m

|

|

50mm x3.6m, 75mm x3.6 m, 100mm x 3.6m, 100mm x 4.8 m, 100mm x9.0m

|

|

||

|

Price

|

1.5 USD-4 USD

|

|

150 USD-300 USD

|

|

||

|

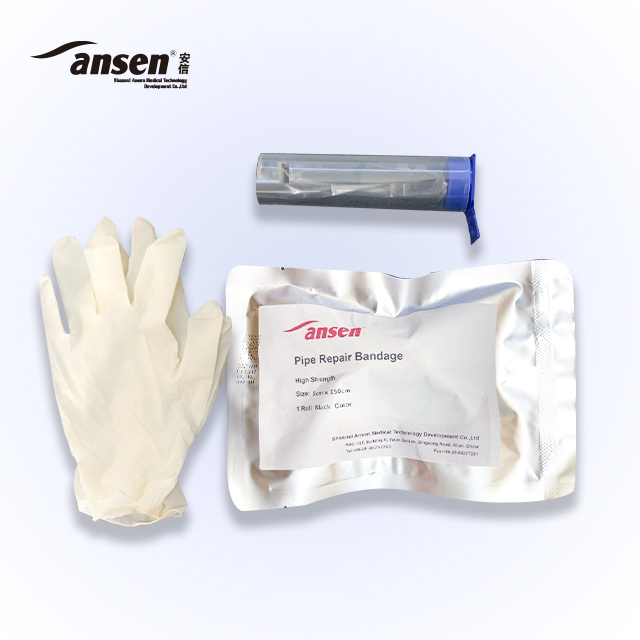

Pipe Repair kit

|

Include Epoxy Putty, Glove, Bandage

|

|

Include Epoxy Putty, Bandage

|

|

||

|

Application

|

Acid Lines Pipe, Oils Pipe, Gas Pipe Water Pipe

|

|

Acid Lines Pipe, Oils Pipe, Gas Pipe Water Pipe

|

|

||

|

Heat Resistance

|

180°C

|

|

150°C

|

|

||

|

Resin Makeup

|

Water-activated Polyurethane

|

|

Water-activated Polyurethane

|

|

||

|

Pressure Resistance

|

Internal Pressure up to 3000 kPa

|

|

Internal Pressure up to 2500 kPa (360 psi)

|

|

||

|

Bonds to Most Pipes

|

Steel Polypipe (PP/HDPE) PVC Fibreglass Copper

|

|

Steel Polypipe (PP/HDPE) PVC Fibreglass Copper

|

|

||

|

Set Time

|

30 minutes, sets under water

|

|

30 minutes, sets under water

|

|

||

Water Utilities Industry/Wastewater Treatment

Ansen Pipe Repair Kits enable the water industry to make rapid live leak repairs to leaking pipes and burst water mains as soon as problems are identified on supply networks.

Permanent repairs which are pressure resistant up to 50 bar can be made to pipes of any diameter or type inside 30 minutes without the need for formal training. Water flow does not need to be turned off to carry out a repair, avoiding costly and disruptive interruptions to supplies.

Permanent repairs which are pressure resistant up to 50 bar can be made to pipes of any diameter or type inside 30 minutes without the need for formal training. Water flow does not need to be turned off to carry out a repair, avoiding costly and disruptive interruptions to supplies.

Oil & Gas Pipeline

The oil and gas industry use both ANSEN Pipe Repair Kits and Pipe Repair System for pipeline repair, refurbishment and reinforcement in harsh and aggressive environments.

Breached pipelines carrying potentially hazardous substances need to be repaired as soon as possible. ANSEN Kits allow for permanent repairs temperature resistant to 200ºC and pressure resistant to 30 bar to be made in under 30 minutes without the need for any formal training.

Breached pipelines carrying potentially hazardous substances need to be repaired as soon as possible. ANSEN Kits allow for permanent repairs temperature resistant to 200ºC and pressure resistant to 30 bar to be made in under 30 minutes without the need for any formal training.

3. Customer Feedback

4.Advantages and Technical Datas

|

Advantages

|

|

Technical Data

|

|

|

|||

|

|

|

|

|

|

|||

|

Emergency Water Activated Fiberglass Fix Pipe Repair Wrap

1. Catalyst: Water 2. Resin Makeup: Polyurethane 3. Heat Resistance: 180°C 4. Pressure: 450 PSI 5. Bonds: Copper pipe, PVC, polypipe, metal, fibreglass 6. Set Time: 20 - 30 minutes, sets under water 7. Chemical resistance: Most diluted chemicals and fuels |

|

1. Useable life: …2-3 minutes, depending on temperature of water and pipework

2. Intial cure time: … 5 minutes 3. Full cure time: … 30minutes 4. Shore D hardness: … 70 5. Tensile strength: … 30-35Mpa 6. Tensile modulus: … 7.5Gpa 7. Maximum service temperature: 150°C 8. Pressure resistance: … 450psi (Min wrapping 12 layers around cracked/leaking area) |

|

|

|||

5. Packing and Shipping

Each bandage is wrapped individually in a bag with outer package

Aluminum Plastic Bag

Hard Inner Box

Outside Corrugated Carton

10bags/box, 9boxes/ctn.

We support shipping in Air or Ocean way, 7-15 working days after payment.

Aluminum Plastic Bag

Hard Inner Box

Outside Corrugated Carton

10bags/box, 9boxes/ctn.

We support shipping in Air or Ocean way, 7-15 working days after payment.

6. Product Operation

1.Once the leaking area is identified, shut down relevant pipes or hoses immediately.

2.Prepare the surface by cleaning and roughening the pipe.

3.Put on enclosed latex gloves.

4.Apply Steel Putty to the leak site and mould.

5.Open foil pouch and immerse bandage in temperate fresh water for 10 seconds,must be used once the package is opened.

6.Apply around the damaged area extending up to 50mm either side of the leak to ensure complete coverage.

7.Quickly as curing begins once it is taken out of the water.

8.Whilst wrapping, pull each layer tightly by using your hand to mould and squeeze the layers together.

2.Prepare the surface by cleaning and roughening the pipe.

3.Put on enclosed latex gloves.

4.Apply Steel Putty to the leak site and mould.

5.Open foil pouch and immerse bandage in temperate fresh water for 10 seconds,must be used once the package is opened.

6.Apply around the damaged area extending up to 50mm either side of the leak to ensure complete coverage.

7.Quickly as curing begins once it is taken out of the water.

8.Whilst wrapping, pull each layer tightly by using your hand to mould and squeeze the layers together.

7. Factory Production Process

7. About us

Shaanxi Ansen Technology Development Co., Ltd is one of leading pipe repair consumable manufacturer in China with more than 15 years history. On Dec 5,2007,Ansen first production line was successfully installed and pilot run.After two years of fast development,Ansen had about 200 distributors in China extended business to foreign area such as Europe, USA , Asia, etc.

Ansen have a vision and philosophy that supply high quality medical consumable to customers at home and abroad within principle of integrity,high efficiency,safe,profession and win-win.

8. How to contact

Hot Searches