- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DY

-

Voltage:

-

380v / as client's demand

-

Weight (KG):

-

100 kg

-

Product name:

-

dust-free powder pneumatic vacuum transport system

-

material:

-

stainless steel

-

Usage:

-

fine powder

-

capacity:

-

0.1t/h - 4 T/h

-

Packing:

-

Plywood Case

-

control system:

-

PLC or other

-

Thickness:

-

2mm

-

Height:

-

2-10m

-

Accessories:

-

provide

Quick Details

-

Power:

-

2.2kw

-

Warranty:

-

1.5 years

-

Width or Diameter:

-

customized

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DY

-

Voltage:

-

380v / as client's demand

-

Weight (KG):

-

100 kg

-

Product name:

-

dust-free powder pneumatic vacuum transport system

-

material:

-

stainless steel

-

Usage:

-

fine powder

-

capacity:

-

0.1t/h - 4 T/h

-

Packing:

-

Plywood Case

-

control system:

-

PLC or other

-

Thickness:

-

2mm

-

Height:

-

2-10m

-

Accessories:

-

provide

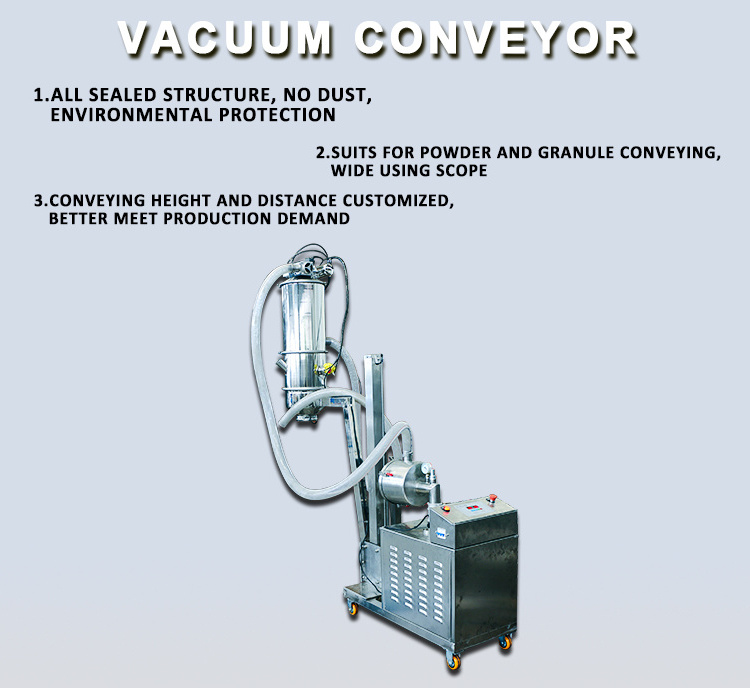

Dust-free powder pneumatic vacuum transport system

Technical Parameter

|

Description

|

Model

|

Power(kw)

|

Capacity (kg/h)

|

|

Electric vacuum conveyor

|

ZKS-1

|

1.5

|

400

|

|

|

ZKS-2

|

2.2

|

600

|

|

|

ZKS-3

|

3

|

1200

|

|

|

ZKS-4

|

5.5

|

2500

|

|

|

ZKS-5

|

5.5

|

3200

|

|

|

ZKS-6

|

5.5

|

3200

|

|

|

ZKS-7

|

7.5

|

6000

|

|

|

ZKS-10-6

|

7.5

|

6000

|

|

|

ZKS-20-5

|

11

|

5000

|

Product Description

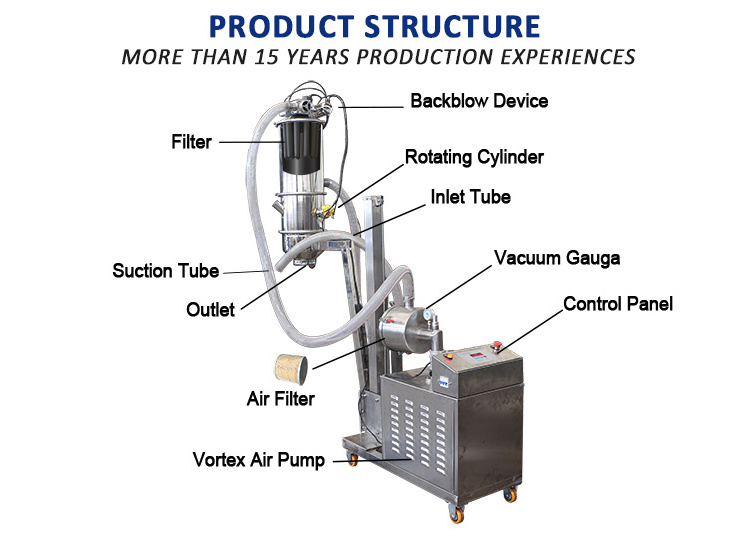

Product Introduction

The ZKS vacuum feeder uses a vacuum pump to suction the air, so that the inlet of the suction nozzle and the whole system are in a certain vacuum state. The powder particles are sucked into the nozzle along with the outside air to form a gas stream, which passes through the suction pipe and reaches the hopper in the hopper. Gas and material separation. The separated material enters the receiving equipment. The feeding and discharging are completed by continuously opening and closing the pneumatic three-way valve, and the opening and closing of the pneumatic three-way valve is controlled by the control center.

The vacuum feeder is equipped with a compressed air back flushing device. Each time the material is discharged, the compressed air pulse back flushing the filter, and the powder adsorbed on the surface of the filter is dropped to ensure the normal operation of the suction.

For the vacuum feeder with material level control, the material in the hopper of the receiving equipment is automatically fed through the material level controller. When the hopper of the receiving equipment is higher than a certain position, the vacuum loading machine stops feeding; when the material level is lower than a certain position, the vacuum loading machine automatically starts to complete the feeding of the receiving equipment.

Product Application

Vacuum conveyors can be widely used in magnetic materials industry, food processing industry, plastic processing industry, lithium power industry, coatings industry, chemical industry and pharmaceutical industry etc.

Related Products

Package & Shippment

Company Profile

Hot Searches