- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V-460V

-

Power:

-

Depend on model

-

Dimension(L*W*H):

-

Depend on model

-

Weight (KG):

-

1000

-

Name:

-

Conveyor Mesh Belt Dryer for Fruit Vegetable Seaweed Pepper Coconut

-

Quantity of unit:

-

4-12

-

Belt width:

-

1.2m-3.85m

-

Length of drying section:

-

8m-24m

-

Operation temperature:

-

50℃-140℃

-

Steam pressure:

-

0.2Mpa-0.8Mpa

-

Drying time:

-

0.2-3h

-

Spare parts:

-

supply the whole lifetime

-

Application material:

-

Vegetable Herbal Fruit Chemical

Quick Details

-

Type:

-

DEHUMidifier

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

maohong

-

Voltage:

-

220V-460V

-

Power:

-

Depend on model

-

Dimension(L*W*H):

-

Depend on model

-

Weight (KG):

-

1000

-

Name:

-

Conveyor Mesh Belt Dryer for Fruit Vegetable Seaweed Pepper Coconut

-

Quantity of unit:

-

4-12

-

Belt width:

-

1.2m-3.85m

-

Length of drying section:

-

8m-24m

-

Operation temperature:

-

50℃-140℃

-

Steam pressure:

-

0.2Mpa-0.8Mpa

-

Drying time:

-

0.2-3h

-

Spare parts:

-

supply the whole lifetime

-

Application material:

-

Vegetable Herbal Fruit Chemical

Product details

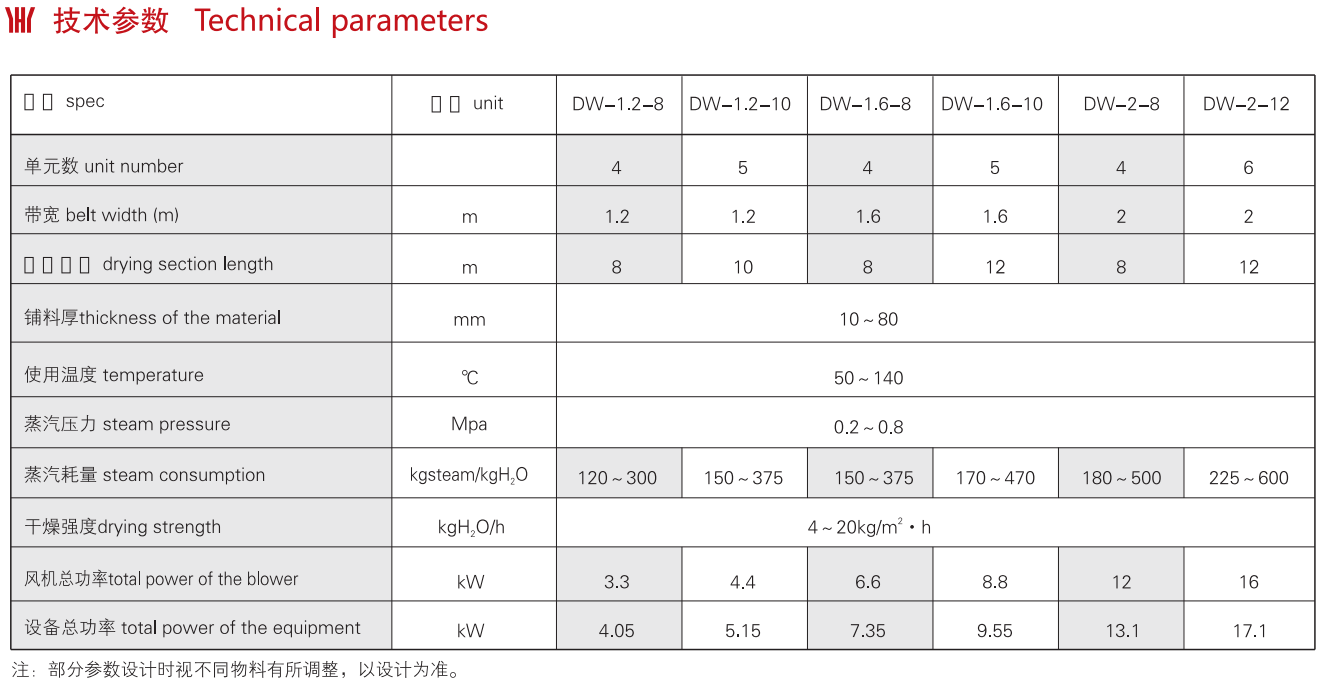

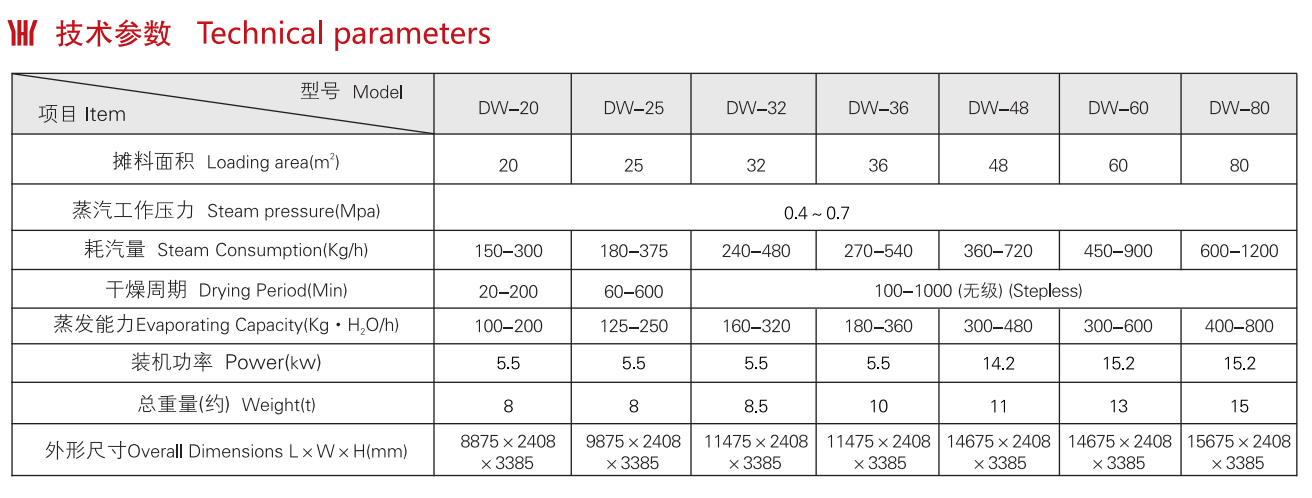

| Name | Conveyor Mesh Belt Dryer for Fruit Vegetable Seaweed Pepper Coconut |

| Material | Stainless steel 304 / 316L, carbon steel |

| Quantity of unit | 4-12 |

| Belt width | 1.2m-3.85m |

| Length of drying section | 8m-24m |

| Operation temperature | 50℃-140℃ |

| Steam pressure | 0.2Mpa-0.8Mpa |

| Drying time | 0.2-3h |

| Spare parts | supply the whole lifetime |

Description

DWC Series band through flow dryer area widdly used in fields of food, agriculture products and by-products, dehydrated vegetable, Chinese herbal medicine, fish products, feed and chemical industry and are suitable for drying of flaked, striped, cube and granule materials.

The drier has the charzcteristics of high efficiency and low energy consumption and possess the domestic advanced level in through flow drying, leading wind layer by large, drying by changing temperature stage by stage and collecting remainder heating. Main specifications have reached 90*s advanced international lever.

The belt converyor of this drier that loads drying material is five layers stainless steel net belt, Because the hot flow bellow to ablve bell layers, heating exvhange conpletly and evenly, production efficiency is high and the product quality are very good, There are cooling layer and vibration device in outlet to decrease in outlet to decrease the final product temperature and make it convenient to package in time.

These driers are equiiiped with elevator with material even device to make the height of material identical, the height of material cna be adjusted by no-step.

These driers have five styles, with belt area from 25-70m2, it can meet the requirment of drying many kinds of materials and different product scale. Our factory cna provide technical serves for consultation, equipment selection, research & design and undeeertaking engineering.

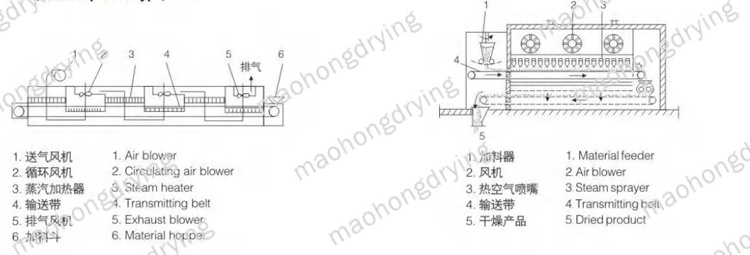

Principle

1. The main structure of DW type cross flow belt dryer is :(1) lower circulation unit; (2) Transmission mechanism system; (3) net belt; (4) steam pipe and cooling water discharge system (and heat conduction oil heating system); (5) dehumidification system; (6) Material forming machine (feeding); (7) upper cycle unit; (8) Bottom powder discharging device; (9) Electrical system and other 9 components

2. Working principle: Consists of feeder hopper in the material evenly on the net, net belt with 20-30 mesh stainless steel wire mesh, a drive device drag moving inside the dryer, dry period of several units, each unit hot air circulation, independent of its exhaust by dedicated platoon is wet exhaust fan, the air volume of every unit has a regulating valve control in circulation on the unit, Circulation fan and the wind had side unit duct into the inferior vena, air flow upwards through the heat exchanger, and the distributor, distribution after blowing into jet stream mesh belt, through the material into the cavity, after drying process is the heat flow through the material layer, heat and mass transfer process, the cavity has a duct is combined with fan, most of the gas cycle, part of the low temperature, Moisture content of the larger gas as exhaust through the exhaust duct, regulating valve, the platoon is wet exhaust fan, can also access dust collector to collect powder, cycle unit, under the circulation fan on the wind into the first chamber, down by the heat exchanger, through material layer, into the inferior vena, inferior vena have side duct and duct connected to the fan into the/back, most of the gas cycle, part of the cell cycle in the discharge, It can be flexibly matched according to the material characteristics of users, and the number of units can also be selected according to the output and the needs of material phase conversion.