- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Injection-AD

-

Plastic parts material:

-

ABS,PVC,PP,PE,PMMA, Arcylic, Nylon, etc.

-

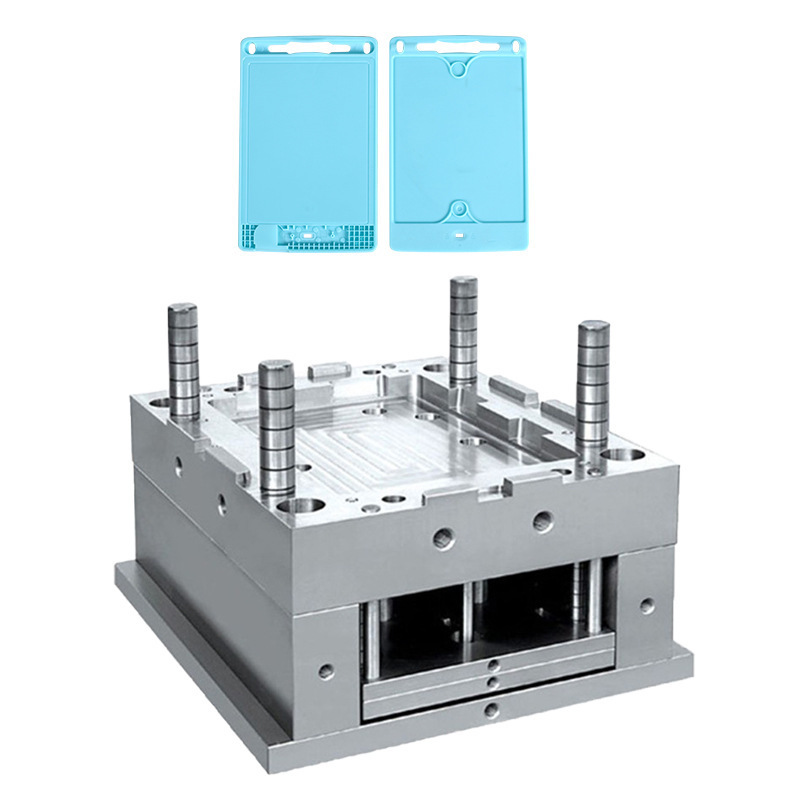

Cavity:

-

single cavity or multi cavity

-

Method:

-

Normal plastic injection

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Mold Life:

-

200,000~1,000,000 shots,or accordign customer requireme

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Increase

-

Model Number:

-

Injection-AD

-

Plastic parts material:

-

ABS,PVC,PP,PE,PMMA, Arcylic, Nylon, etc.

-

Cavity:

-

single cavity or multi cavity

-

Method:

-

Normal plastic injection

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Mold Life:

-

200,000~1,000,000 shots,or accordign customer requireme

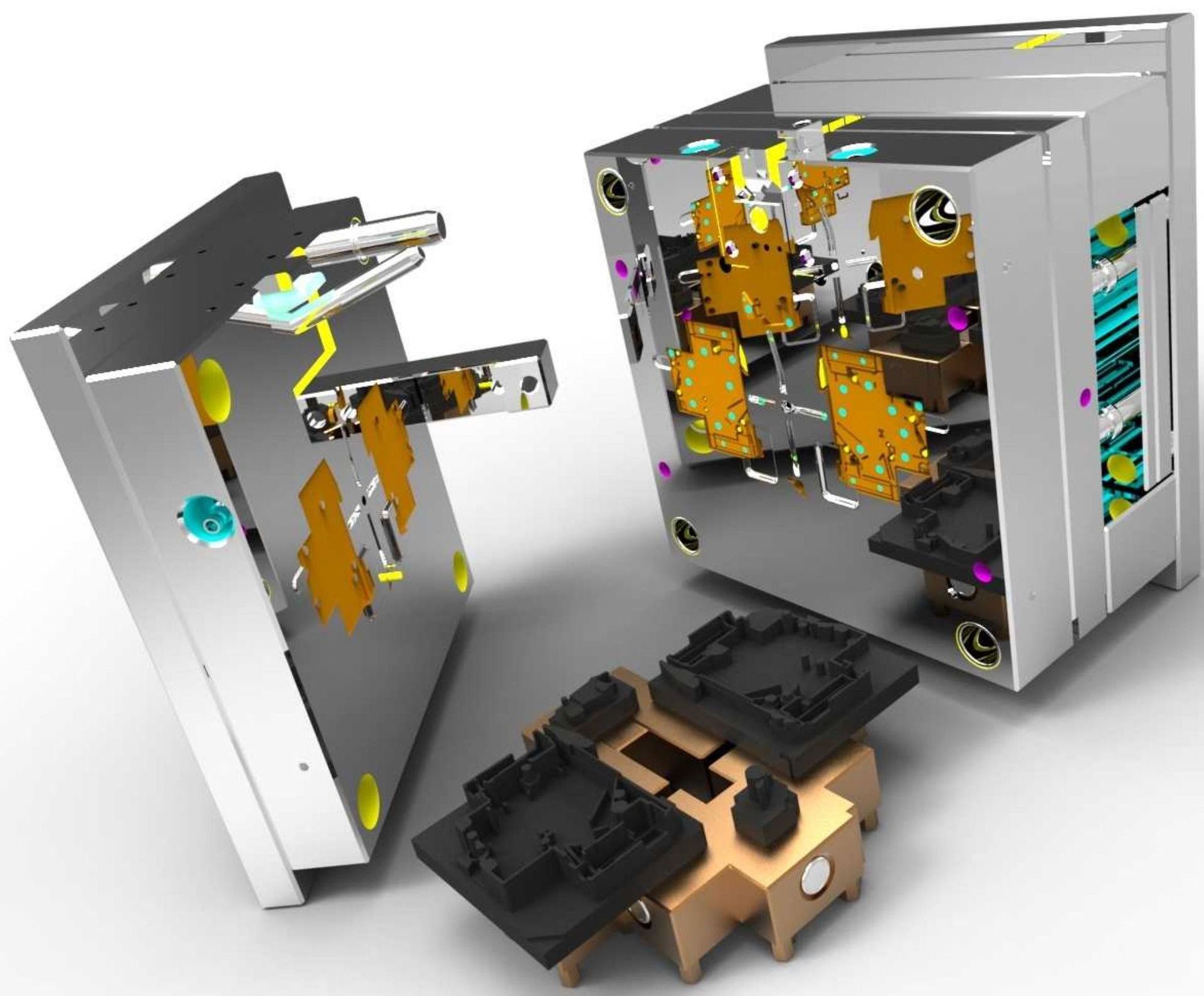

| Mold Material | S136, 718, 738, P20, NAK80,P20, 718H, 738H, S136H |

| Plastic Material | PVC/PA66/PC/PE/POM/PMMA/ABS/TPU/TPE/PE/PP.ETC. |

| Mold Cavity | multi-cavity or single cavity |

| Mold life | 300,000-500,000 shots |

| Mold Runner | hot runner/cold runner |

| Mold Base | LKM, HASCO, ETC. |

| Size |

1) According to customers' drawings

2) According to customers' samples |

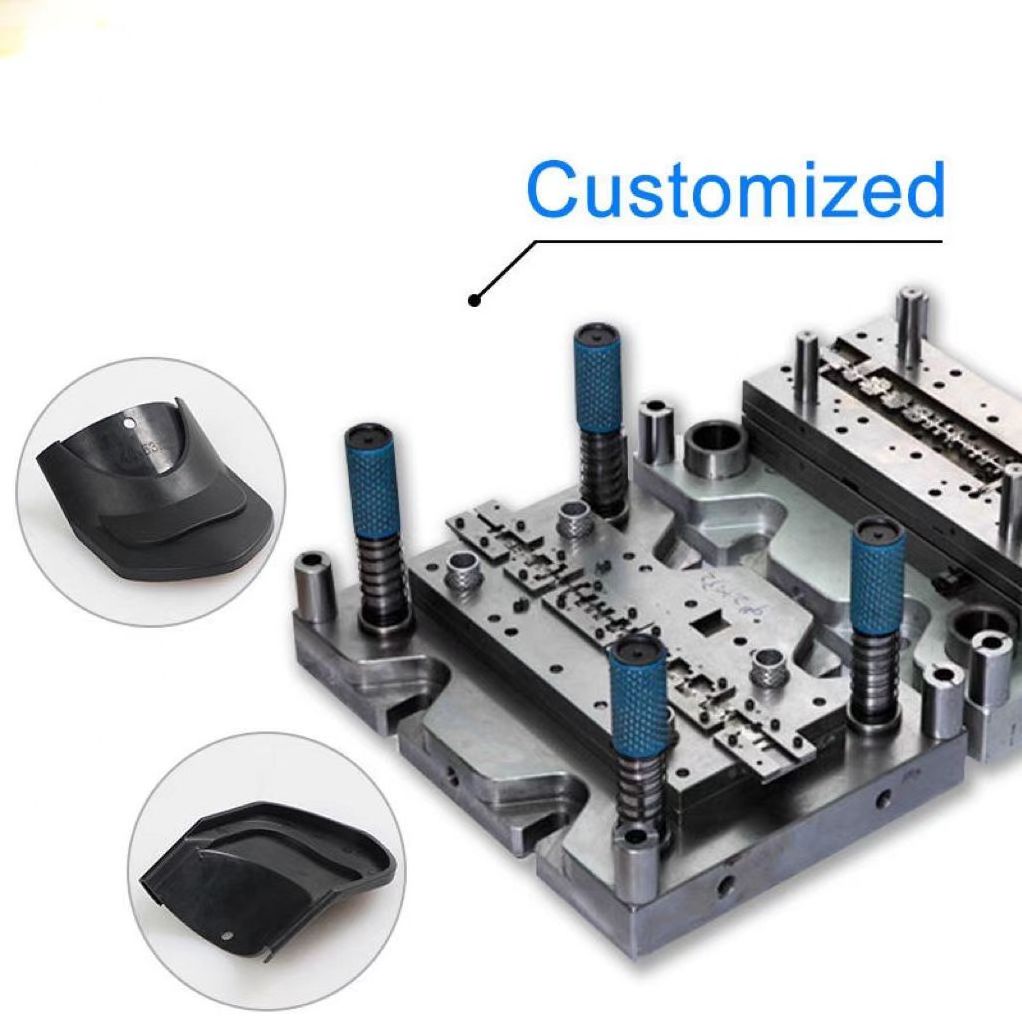

| Surface Treatment | Polishing, Electroplating, Smooth, glossy, textured, matte. |

| Delivery Time |

For mold making: 3-4 weeks For injection production: 1-2 weeks (up to your order quantity) |

| Design Software | Solidworks, Pro-E, CAD |

| Certification | ISO9001: 2015 |

| Payment Term | T/T, Paypal, Trade Assurance |

|

||

|

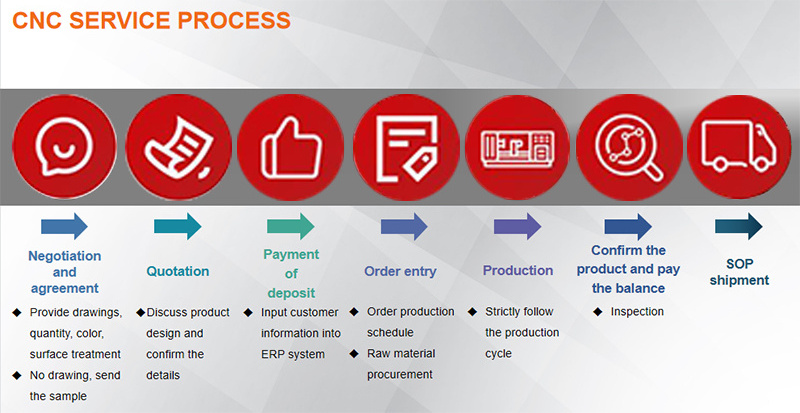

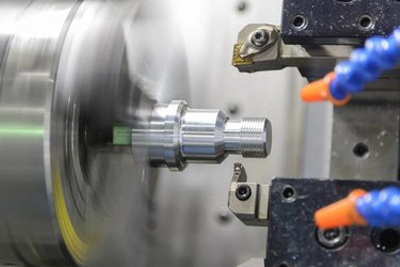

CNC Turning

|

|

CNC Milling

It is a computer-controlled process involving using a cutting tool to remove part of a workpiece. The basic setup involves placing the workpiece on the machine’s table while the cutting tool/s attached to the spindle rotates and moves to shape the workpiece into a finished product. |

|

CNC Drilling

|