- Product Details

- {{item.text}}

Quick Details

-

Certification:

-

ISO9001-2015

-

Payment terms:

-

T/T 50%deposit 50%balance

-

Tolerance:

-

0.01-0.05mm

-

Popular Color:

-

customed color

-

Quality control:

-

100% Inspection

-

Roughness:

-

Ra0.2-Ra3.2 (Custom Available)

-

MOQ:

-

Small Orders Accepted

-

Service:

-

One Stop Service. Machining-assembly

-

Surface Treatments::

-

Powder Coating,Polishing,Brusing,Plating,Anodizing,PVD Coating etc

-

Die Casting Material Capabilities::

-

Aluminum Alloy, Zinc Alloy, Brass Alloy etc

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XRD

-

Model Number:

-

N0884

-

Certification:

-

ISO9001-2015

-

Payment terms:

-

T/T 50%deposit 50%balance

-

Tolerance:

-

0.01-0.05mm

-

Popular Color:

-

customed color

-

Quality control:

-

100% Inspection

-

Roughness:

-

Ra0.2-Ra3.2 (Custom Available)

-

MOQ:

-

Small Orders Accepted

-

Service:

-

One Stop Service. Machining-assembly

-

Surface Treatments::

-

Powder Coating,Polishing,Brusing,Plating,Anodizing,PVD Coating etc

-

Die Casting Material Capabilities::

-

Aluminum Alloy, Zinc Alloy, Brass Alloy etc

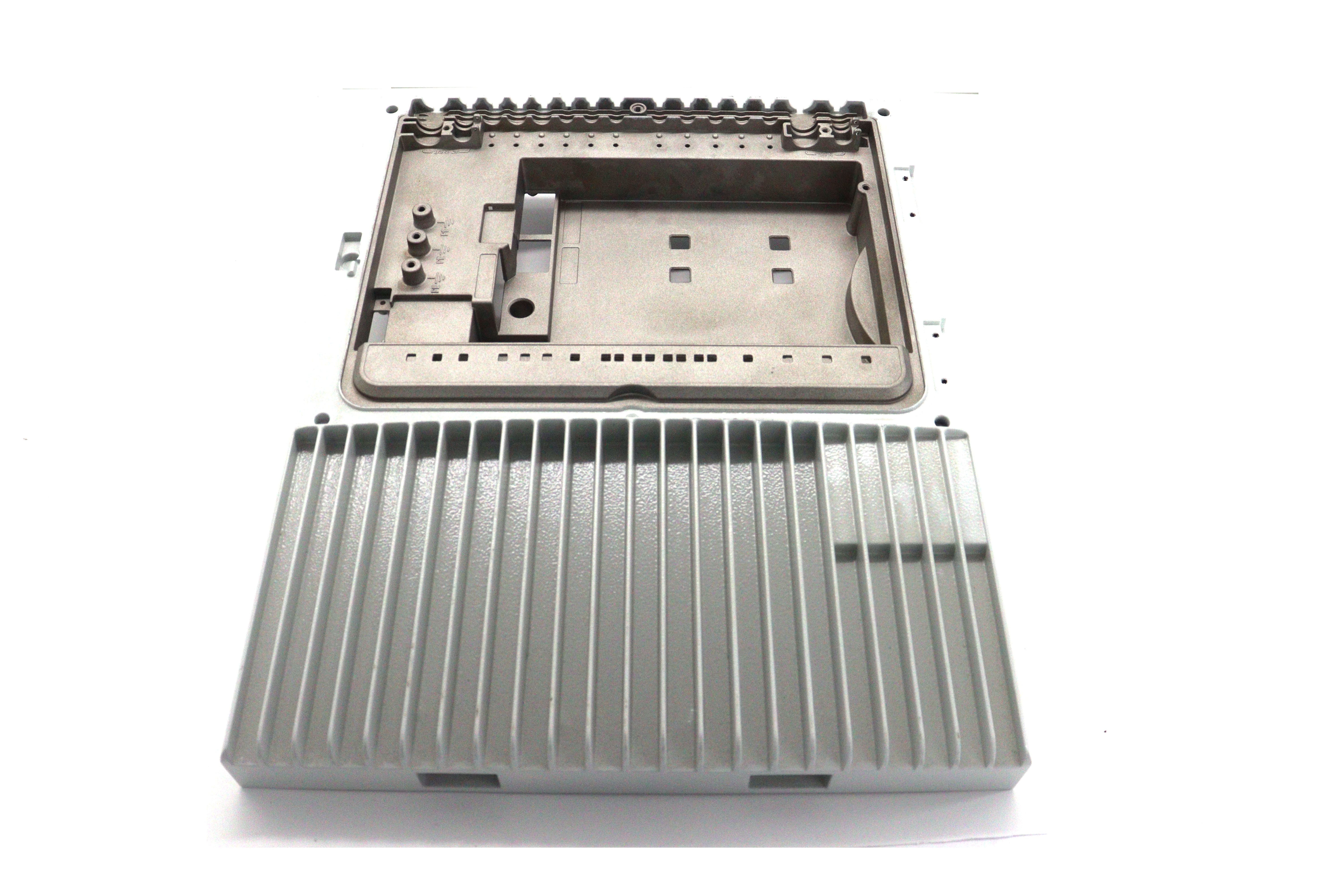

customize high quality stainless steel aluminum zinc alloy long life investment silver bronze cast extrusion die casting product

|

Manufacturer:

|

Dongguan Xinruida Precision Technology Co., Ltd

|

|

|

|

|||

|

Materials:

|

1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24

2) Zinc alloy 3#, 5#, 8# |

|

|

|

|||

|

Surface Treatment:

|

1) Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast, anodine

2) Polish + zinc plating/chrome plating/pearl chrome plating/nickel plating/copper plating |

|

|

|

|||

|

Tolerance:

|

+/-0.005mm, 100% QC quality inspection before delivery, can provide quality inspection form

|

|

|

|

|||

|

Testing equipment:

|

CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement

|

|

|

|

|||

|

Service Project:

|

To provide production design, production and technical service, mould development and processing, etc

|

|

|

|

|||

|

Quality Assurance:

|

ISO9001:2015 Certified.TUV

|

|

|

|

|||

|

File Formats:

|

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc.

|

|

|

|

|||

Die Casting Advantages

Die casting can have significant advantages over other manufacturing processes, which often lead to major cost savings, not only in the part price itself but also in the overall cost of production. When you cast a part, you can create complex net shapes, including external threads and complex internal features with minimal draft angles—minimizing secondary operations. You can also combine multiple parts into a single part, eliminating assembly operations and lowering labor costs, with the added benefits of simplified stock control and greater component consistency.

Other benefits include:

Variable wall thicknesses

Tighter tolerances

Fewer steps from raw material to finished part

Fast production cycle times

Reduction in material scrap

Long tool life, especially for zinc and magnesium

Die Casting Alloys

Zinc, aluminum, and magnesium are the three main die casting alloys. They are normally non-ferrous and their mechanical properties vary greatly to fit almost every type of application a manufacturer may need. Not only can die cast alloys withstand high operating temperatures, but they are also fully recyclable.

Die cast alloys also have:

Good corrosion resistance

High strength and hardness

High thermal conductivity

High electrical conductivity

Outstanding EMI/RFI shielding properties

Good finishing characteristics

Separately, each die cast alloy offers a variety of benefits that the other may not offer. That is one of the great things about die casting, you do not have to be limited when it comes to choosing the right metal.

Specification

Dongguan Xinruida Precision Technology Co., Ltd., founded in 2004, is one of leading professional manufacturer of metal parts in China,our main products include customized high precision machinery parts, precision metal stamping parts and sub-assembly( including welding & riveting).

Our main production equipments and inspection equipments are imported from Germany and Japan, our five-axis CNC machining center with brand Hermle Germany & Matsuura Japan can ensure much tight tolerance to 0.002mm during manufacturing process,we can produce about 5,000 to 10,000 pcs machining parts and 600,000 stamping parts every day,small orders are acceptable as well.

Our products are widely used in Industrial automation devices, Vacuum and Aviation devices, Electronics and Communication Devices, Mechanical Equipments and Medical Equipments.

Our factory are certified with I S O 9 0 0 1:2 0 1 5, We have professional engineer support, high efficiency sales team and competitive price superiority, excellent quality and most competitive price plus dedicated, professional and caring Xinruida people attract many customers from all over the world including ASML,HUAWEI,BOSCH and Schneider,furthermore we export to over 30 countries including USA, Canada, Europe, Russia, Mexico, Brazil, India, Thailand ,Middle East and South Africa and so on.

We sincerely welcome you and look forward to cooperating with you for a bright future!

Hot Searches