- Product Details

- {{item.text}}

Quick Details

-

Cooling Mode:

-

water cooling

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CFine

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

4550*1660*2015 mm

-

Year:

-

NEW PRODUCT

-

Power (kW):

-

55KW

-

Weight (KG):

-

10000 KG

-

Applicable Industries:

-

Rubber plastic industry, Rubber and plastic industry

-

Product name:

-

Open Mixing Two Roll Mill

-

Control System:

-

Imported "SIEMENS"

-

Application:

-

Rubber Compound Mixing,sheeting,

-

Certification:

-

CE, ISO9001, TUV

-

Roller Dimensions:

-

450*1200 mm

-

Front roll line speed:

-

21.1 r/min

-

Maximum Roll Distance:

-

12 mm

Quick Details

-

Diameter of Roll(mm):

-

450 mm

-

Length of Roll(mm):

-

1200 mm

-

Roll Ratio(Front/Back):

-

1:1.27

-

Cooling Mode:

-

water cooling

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CFine

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

4550*1660*2015 mm

-

Year:

-

NEW PRODUCT

-

Power (kW):

-

55KW

-

Weight (KG):

-

10000 KG

-

Applicable Industries:

-

Rubber plastic industry, Rubber and plastic industry

-

Product name:

-

Open Mixing Two Roll Mill

-

Control System:

-

Imported "SIEMENS"

-

Application:

-

Rubber Compound Mixing,sheeting,

-

Certification:

-

CE, ISO9001, TUV

-

Roller Dimensions:

-

450*1200 mm

-

Front roll line speed:

-

21.1 r/min

-

Maximum Roll Distance:

-

12 mm

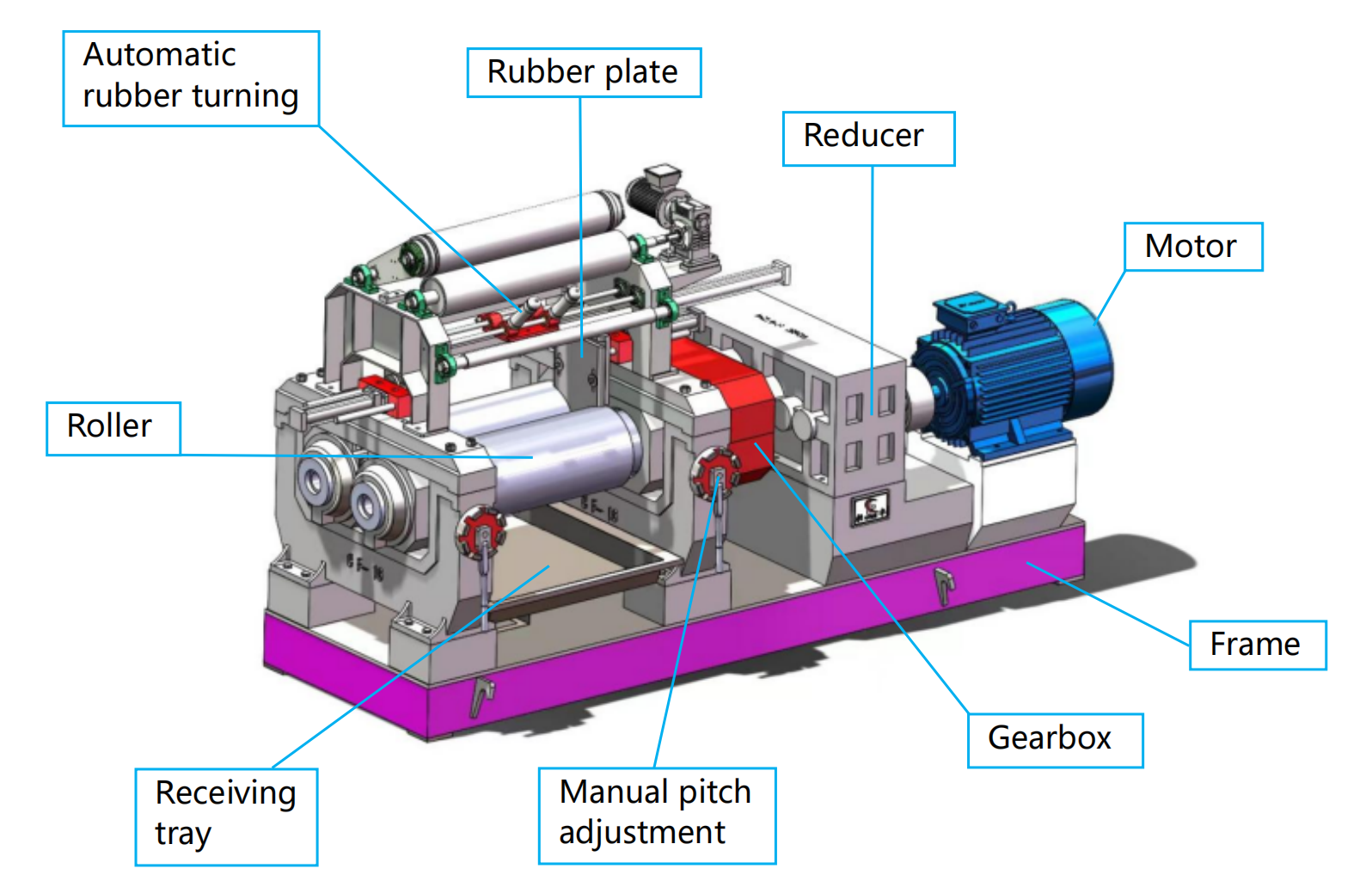

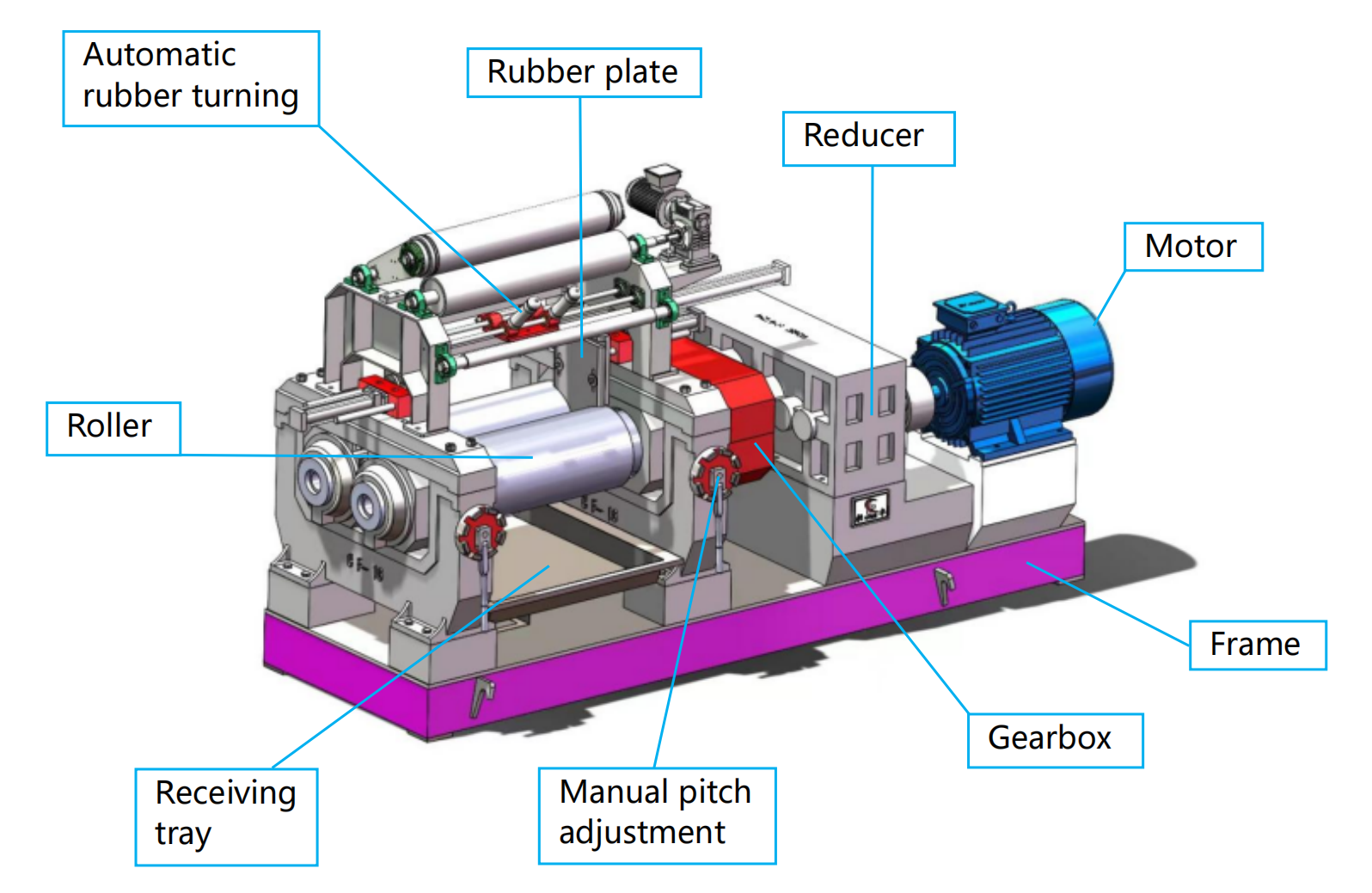

1.

Mainly used for: natural rubber, synthetic rubber, silicone, EPDM, fluororubber, EVA, PVC, TPE and other materials for molding, tablet production and other processes.

2.

Bearing seat: Made of high-quality steel precision casting and processed with high-precision CNC, it has strong load-bearing capacity and good seismic resistance.

3.

Bearing lubrication: Adopting a forced circulation lubricating oil system toreduce manual maintenance.

4.

Base: Made of high-quality steel plates welded together, with anintegrated structure and good seismic resistance.

5.

Roller pitch adjustment: can be customized according to customerrequirements, electric adjustment or oil pressure adjustment.

6.

Rubber flipping: Can be customized according to customer. requirements, with an automatic glue flipping system to reduce manual labor intensity.

7.

Operation: The equipment is easy to operate and easy to maintain.

8.

Safety: Install emergency stop buttons in front and back for quick shutdown.

Guangdong CFine Technology Co., Ltd. was established in 2013, is a manufacturer that specialized in designing, R&D, manufacturing, selling and maintain the plastic,rubber, powder metallurgy mixing and granulating equipments. The company has a unique courtyard, covering an area of 12000 square meters, a building area of 10000 square meters, and a team of nearly 100 people.

We have very professional R&D team to meet the special requirements of customers, to custom-made the machine.

We have strong technical strength, full range of advanced equipments and well -trained manufacturing team, together with modern management mode, convenient and swift after-sale service, thus our machines are sold more than 100 countries, obtained accordant appreciation by the clients and we had established long-term and stable relationships of cooperation.

Quality first,service uppermost is our guideline. Honesty and integrity, innovation contribution is our principle. C Fine is becoming the most professional and influential manufacturer in this industry, C Fine brand is most popular in China, and also available to the world in the near future!

Hot Searches