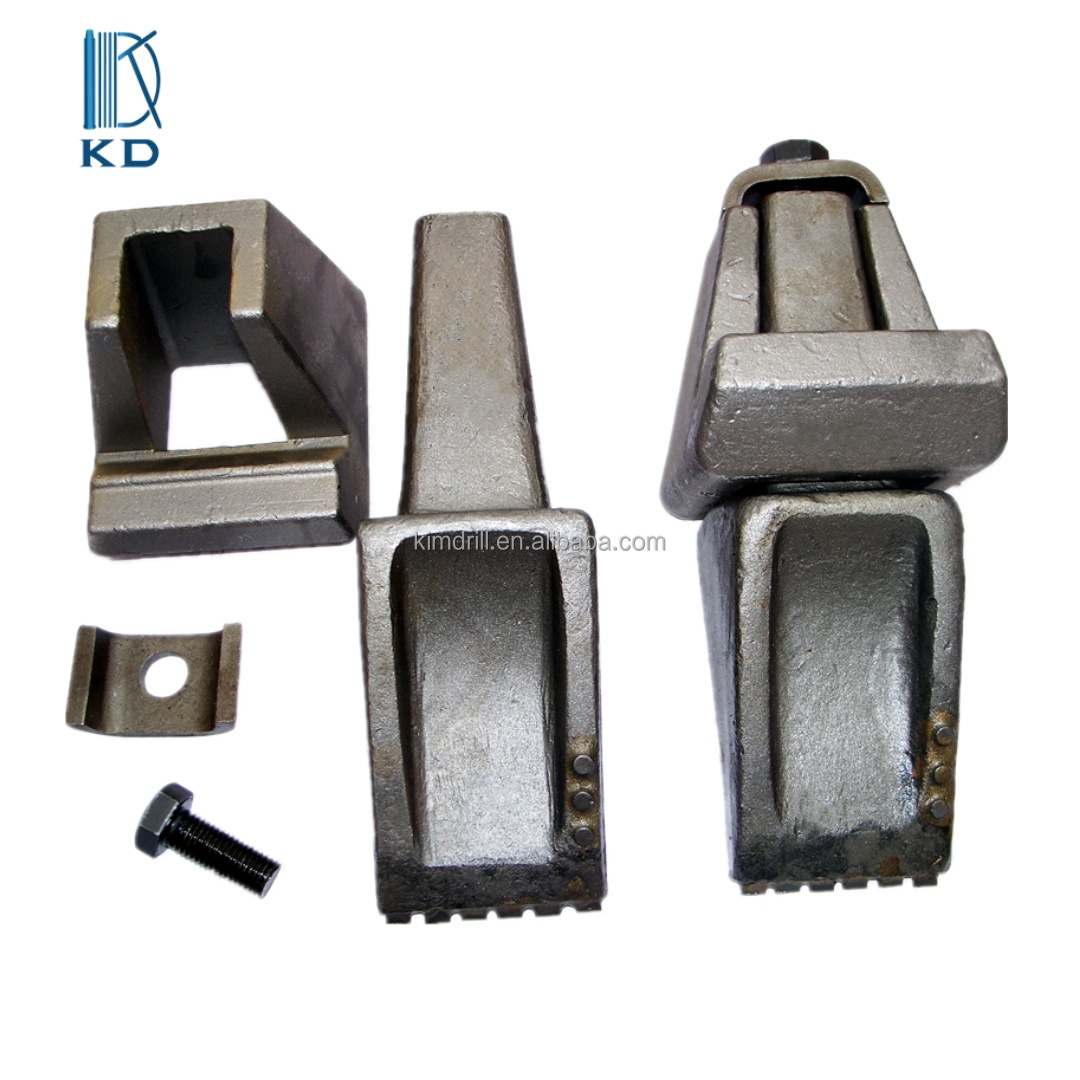

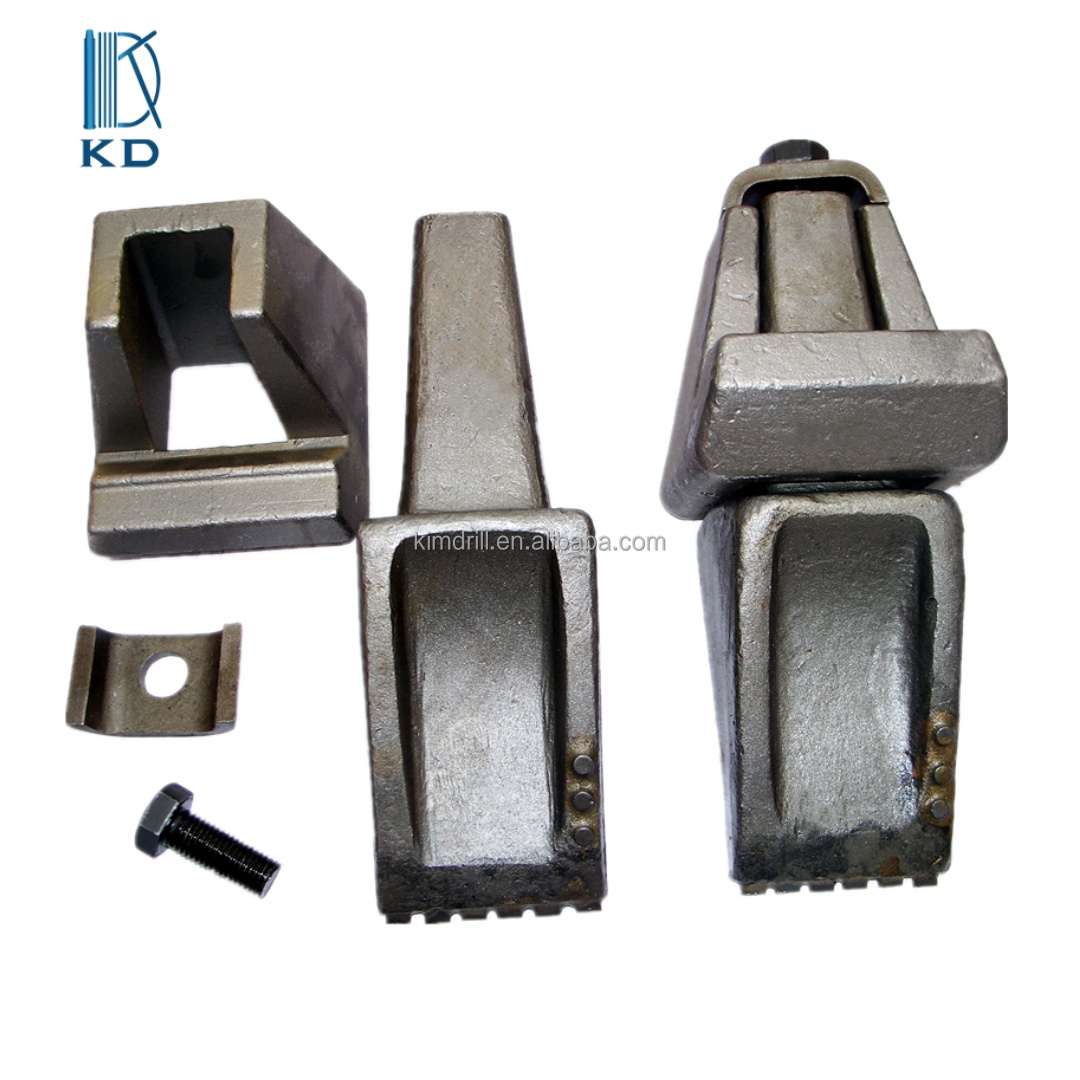

Cost-Efficiency:

Given its durability and versatility, the flat teeth reduces the need for frequent replacements, leading to cost savings in the long run.

Safety:

The precision and efficiency of the flat teeth reduce the chances of mishaps or inaccuracies during drilling, ensuring safer operations.

Ease of Use:

Despite its advanced

features, the flat teeth is designed to be user-friendly, ensuring that even those new to the drilling world can use it effectively.

features, the flat teeth is designed to be user-friendly, ensuring that even those new to the drilling world can use it effectively.