- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

Flexo printing machine for carton box

-

Automatic Grade:

-

Automatic

-

Color Group:

-

Everything can be equipped according to user's needs.

-

Printing Paper:

-

A, B, C, A/B, B/C, A/B/C.

-

Standard Printing Plate Thickness:

-

7.2MM

-

Certification:

-

CE, ISO

Quick Details

-

Brand Name:

-

Rino

-

Marketing Type:

-

Hot Product 2023

-

Weight (KG):

-

15000 KG

-

Product Name:

-

Flexo printing machine for carton box

-

Automatic Grade:

-

Automatic

-

Color Group:

-

Everything can be equipped according to user's needs.

-

Printing Paper:

-

A, B, C, A/B, B/C, A/B/C.

-

Standard Printing Plate Thickness:

-

7.2MM

-

Certification:

-

CE, ISO

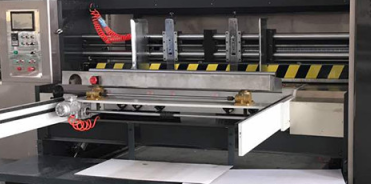

Carton Box Cardboard Flexo Printing Slotting Die Cutting Machine

| Features of Corrugated Flexo Printing Machine |

1. Computer order storage and adjustment , faster order update and convenient operation .

2. Complete machine wallboard and other important pieces are all made by high precision process center and grinded by digit-controlled grinder.

3. All the transmission axle and rollers are made of high-quality steel with high-precision dynamic balance , plated with rigid chrome and grinded surface.

4. The transmission gear adopts the high-quality steel , which is grinded after heat-treatment , after long use , it still maintains the high topping precision.

5. The main machine transmission parts adopt the hand-free connection ring to eliminate the interval, suitable for long-term high speed printing.

6. The whole machine undergoes the spray lubrication and is equipped with engine oil automatic balance facilities.

7. It possesses the print , die-cutting , slotting memory function , which could return to Zero and Re-set automatically.

8. PCLINK control network , MCGS software , Siemens low voltage electric appliance and host frequency conversion control , 30% electricity saving.

9. Double axle slotting to configure whole machine production management computer control system and single axle slotting to configure whole machine production management computer control system.

10. Edge leader feeding system.

| Parameters of Corrugated Flexo Printing Machine |

|

Model |

HRT-160-900 |

HRT-160-1200 |

HRT-160-1400 |

|||

|

Color Group |

Everything can be equipped according to user’s needs. |

|||||

|

Printing Paper |

A, B, C, A/B, B/C, A/B/C. |

|||||

|

Production Speed |

200pcs/min |

180pcs/min |

160pcs/min |

|||

|

Max. Paper Sizes |

900*1800/2000/ 2200/2400/2600mm |

1200*1800/2000 /2200/2400/ 2600mm |

1400*1800/2000/2200 /2400 / 2600mm |

|||

|

Min. Paper Sizes

|

Positive knife |

300*640mm |

350*720mm |

400*720mm |

||

|

Negative knife |

300*720mm | 350*740mm | 400*740mm | |||

|

Max. Printing Sizes |

900*1600/1800 /2000/2200/ 2400mm |

1200*1600/1800 /2000/2200/ 2400mm |

1400*1600/1800 /2000/2200/ 2400mm |

|||

|

Max. Die-cutting Sizes |

900*1700/1900 /2100/2300/ 2500mm |

1200*1700/1900 /2100/2300/ 2500mm |

1400*1700/1900 /2100/2300/ 2500mm |

|||

|

Standard Printing Plate Thickness |

7.2mm |

|||||

|

Printing |

Roller Dia. |

300mm |

408mm |

480mm |

||

| Details of Corrugated Flexo Printing Machine |

|

Paper feeding unit 1. Adopt servo motor driver multi-axis no pressure feeding system, no mechanical transmission error. 2. Without full extension type paper glue of shaft transmission , implementation is true in the sense of zero damage, can prevent the deformation of cardboard an guarantee the accuracy of the paper. 3. Vacuum Suction lead edge feed and adjust the paper size as per pressure of wind. 4. Installing suck removing dust machine to eliminate the odd on the printing plate and improve the printing quality. 5. Non side breakage technology to decrease transmission difference to min degree. 6. Without equipping oil recycling and lubrication structure, and it is friendly to environment . |

|

Printing unit 1. Both printing cylinder and impression cylinder are made of high quality steel with grounding surface and chrome plated. 2. Dynamic and static balance correction ensure to run stability. 3. Adopt hanging structure , convenience and fast to set up. 4. Installing and uninstalling printing plate with pedal switch. 5. Working with feeding unit and automatic developer system ( during the feeding unit runs , the anvil roller goes down to contact with printing plate, while, on contract, leave printing plate. ) 6. Printing phrase adjustment adopt touch-screen , which is finished by servo driven program automatically. 7. Printing roller keep the function of zero return and can reset in dynamic and static condition. 8. Cermiacal anvil roller work with close scrapping ink structure . 80-150printing line is available. 9. Pneumatic diaphragm pump control pump to supply and exclude ink , convenience to wash. 10. Duralumin arch shape scrapping ink container make anti-curved ability increase by 30% and save 20% for ink reversion. 11. Coating with friendly environment |

|

Die cutting unit 1. Die cutting department were driven by servo-motor independently to keep coordination with feeding, printing according to all kind of range of die cutter speed. 2. Motor control the gap between rubber roller and mould roller digit display. 3. Without phase adjustment and speed different compensate device , the machine still can keep the speed of die cutter equal. 4. With air-operated elevator device. 5. Without side breakage transmission structure and injecting gear oil to lubricate. 6. The service life of rubber cushion is longer 15%-25% than others |

Slotting Unit

1.Slotting phases was adopted the planetary gear structure, the electric digit 360° adjustment, show the digit (stop, running can adjustment).

|

| Related Products |

| Multi-colors printing machine with slotter | Rotary creasing and die cutting machine | Carton box gluer machine |

| Packaging & Shipping |

Package: Covered with plastic film

Delivery time: Within 40 working days after receiving deposit. It is up to the current monthly production task.

| Services |

- 24h online for service;

- Professional service team;

- Installation and debugging service;

- On time delivery

- Provide the quality assurance of our product

- Offer the details of install mechanical parts and circuit diagram, it will help you to know our machine

- Train your workers in our company freely or send our engineer to your company costly

- Provide long-distance guidance with e-mail or video freely or transport the broken part