- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

+- 0.1

-

Voltage:

-

1P 220V/60Hz

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JOYGOAL

-

Dimension(L*W*H):

-

(L)1300*(W)1200*(H)2000 mm

-

Weight:

-

900 KG

-

Model:

-

KFZ-1

-

Filling heads:

-

1 nozzle

-

Filling volume:

-

2-30 gram (can be adjusted)

-

Air consumption:

-

0.6 m3 /min

-

Power source:

-

Power source

-

Temperature:

-

0-300 °C

Quick Details

-

Machinery Capacity:

-

3000

-

Packaging Material:

-

Plastic, Paper, Metal, Wood, Other

-

Filling Material:

-

Powder

-

Filling Accuracy:

-

+- 0.1

-

Voltage:

-

1P 220V/60Hz

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JOYGOAL

-

Dimension(L*W*H):

-

(L)1300*(W)1200*(H)2000 mm

-

Weight:

-

900 KG

-

Model:

-

KFZ-1

-

Filling heads:

-

1 nozzle

-

Filling volume:

-

2-30 gram (can be adjusted)

-

Air consumption:

-

0.6 m3 /min

-

Power source:

-

Power source

-

Temperature:

-

0-300 °C

This is a rotary type machine that is designed for powder products to be filled and sealed inside empty K cup cap sule specially. It applied with world famous electrical and pneumatic components, convenient and reliable. The features are compact structure, high automation, easy to use, stable performance, simple maintenance, and high production efficiency and 24-hour continuous work. With castors, easy to place where you need.

The table speed of the rotary table is of 40-50 cycles per minute for 12 stations. With a single track 40-50 are produced coffee capsules per minute or soluble products in general.

Material of machine:

l Body of machine is made of painted steel and covered by stainless steel.

l All parts in contact with product are made of stainless steel 304.

l Rotary table and mold plates are made of black gold oxidated aluminum.

l Safety dustpoof cover doors are made of acrylic.

l Sealing head is made of high quality cooper.

Safety:

l Dustproof safety cover the whole machine except operating HMI and output transporting conveyor belt.

l Machine stops if the door is opened, this function is optional, and operator can choose to turn it off when needs to open door for debugging.

l Equipped with 3 colors troubleshooting lamp.

l Protection: Compressed air gas disconnected, machine will not work. Compressed air pressure not enough, machine will stop automatic. Incorrect voltage phase connection, machine will not work. Cylinder with magnetic limited switch, prevents parts breaking down.

|

Model |

KFZ-1 |

|

Filling heads |

1 nozzle |

|

Capacity |

2500-3000 cup/hour |

|

Filling volume |

2-30 gram (can be adjusted) |

|

Accurate |

+- 0. 1 gram |

|

Power |

2.0 Kw / |

|

Air consumption |

|

|

1P 220V/60Hz |

|

|

Temperature |

|

|

Weight |

|

|

Size (mm) |

(L)1 3 00*(W)1 2 00*(H) 2000 mm |

|

Wooden(mm) |

(L)1 4 00*(W)1 3 00*(H)2 25 0 mm |

Ø Empty Capsule Dispensing into Mold One by One

Ø Nitrogen Flushing into Empty Capsule 1 st & into Hopper 2 nd

Ø No Capsule not Filling

Ø Feeding Ground Coffee into Hopper Automatic by Vacuum Feeder ( m achine include vacuum feeder )

Ø Ground Coffee Filling

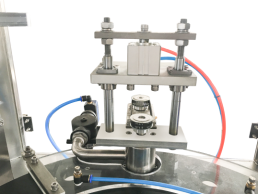

Ø Coffee Pressing & Capsule Rim Cleaning

Ø Nitrogen Flushing 3 rd

Ø Foil Lid Dispensing onto Filled Capsules

Ø No Lid not Sealing

Ø Pneumatic Type Heat Sealing

Ø Finished Capsules Output & Conveyor Belt Transporting