Gasket

cutting machine can perfect cut on gasket, fabric, leather, cardboard, plastic, paper, rubber, EVA foam, and it can cut many types

of foam, such as closed cell foam, rubber foam, foamex, foam core, KT board, EPE foam, polyethylene foam, PE foam, PVC foaAm, etc.

It's widely used for packaging protection, advertising display, termal insulation, model & mock up making, puzzle and pattern

cutting, etc.

- Product Details

- {{item.text}}

Quick Details

-

Applicable Material:

-

Paperboard,grey board,KT board, car sticker

-

Cutting(working) Area::

-

1600mm*2500mm

-

warranty of components:

-

3 years

-

cutting speed:

-

200mm/s-2000mm/s

-

Cutting Thickness::

-

0-50mm

-

Repeat precision:

-

0.05

-

Warranty::

-

3 years

-

Motor::

-

Japan yaskawa Servo Motor

-

Core Components::

-

Pressure vessel, Motor, Bearing,

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AOL

-

Application:

-

Cutting

-

Applicable Material:

-

Paperboard,grey board,KT board, car sticker

-

Cutting(working) Area::

-

1600mm*2500mm

-

warranty of components:

-

3 years

-

cutting speed:

-

200mm/s-2000mm/s

-

Cutting Thickness::

-

0-50mm

-

Repeat precision:

-

0.05

-

Warranty::

-

3 years

-

Motor::

-

Japan yaskawa Servo Motor

-

Core Components::

-

Pressure vessel, Motor, Bearing,

Product Description

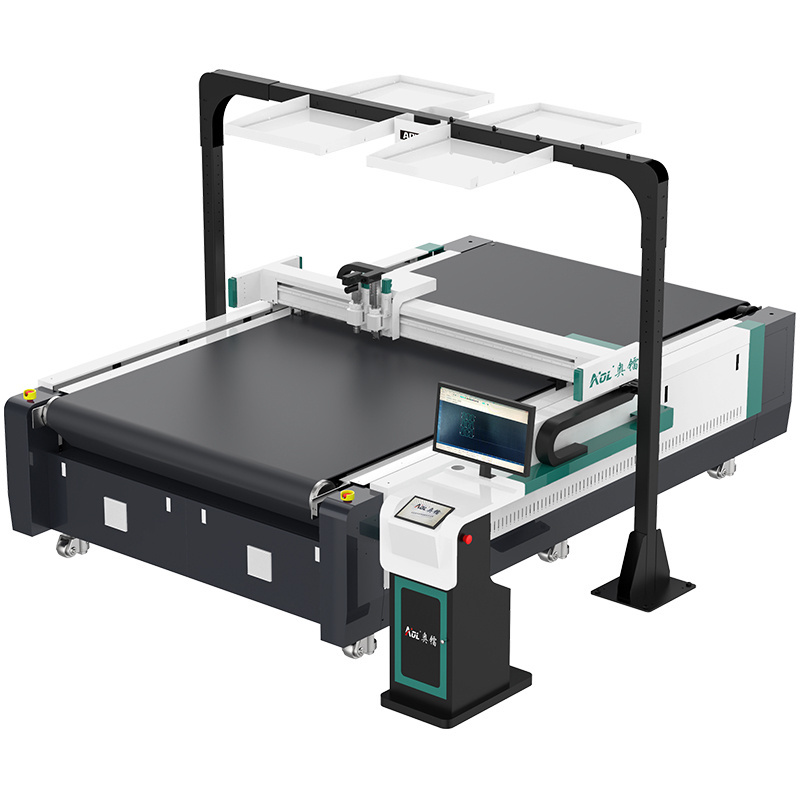

AOL CNC automatic asbestos gasket cutting machine

AOL CNC automatic asbestos gasket cutting machine

Features of CNC gasket cutting machine: Computer controlled cutting of gasket materials straight from the CAD-system: production

of items from single pieces to small batch production, with always the same precision, without the detour via the expensive die

mould, immediately, without lost time due to preparation of the die mould. AOL CNC gasket cutting machine are the system solution

for the professional manufacture of gaskets. The basic machine cutting table with integrated vacuum system. Due to adjustable

matrix-vacuum zones, the material is securely fixed during processing without the aid of mechanical clamps

of items from single pieces to small batch production, with always the same precision, without the detour via the expensive die

mould, immediately, without lost time due to preparation of the die mould. AOL CNC gasket cutting machine are the system solution

for the professional manufacture of gaskets. The basic machine cutting table with integrated vacuum system. Due to adjustable

matrix-vacuum zones, the material is securely fixed during processing without the aid of mechanical clamps

AOL CNC automatic asbestos gasket cutting machine

Details Images

Specification

AOL CNC automatic asbestos gasket cutting machine

|

Technical parameters / model

|

AOL-1212

|

AOL-1625

ZS6 |

AOL-1825

ZS8 |

AOL-2125

ZS10 |

Accept different model

|

|

Effective working area

|

1300mm*1300mm

|

1600mm*2500mm

|

1800mm*2500mm

|

2100mm*2500mm

|

|

|

Multi-head optional

|

Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized

|

|

|

|

|

||||

|

Multi-function tool

|

Vibrating knife full cutting, high power active round knife, punching tool, pneumatic knife,etc.

|

|

|

|

|

||||

|

safety devices

|

Safety devices use infrared sensing, safe and reliable

|

|

|

|

|

||||

|

Cutting speed

|

500-2000mm/s

|

|

|

|

|

||||

|

Cutting thickness

|

≤60mm Other thicknesses can be customized according to the material

|

|

|

|

|

||||

|

Applicable materials

|

Glass fiber, glass fiber cotton, prepreg, carbon fiber, carbon fiber felt, boron fiber, aramid fiber, ceramic fiber, soft glass,

PVC, leather leather, sponge composite skin, XPE material, wire ring, leather, soft glass , silicone, rubber material etc composite soft material |

|

|

|

|

||||

|

Material fixing method

|

Vacuum partition adsorption

|

|

|

|

|

||||

|

Transmission port

|

Network port

|

|

|

|

|

||||

|

Transmission system

|

Yaskawa servo motor, linear linear guide, timing belt, lead screw

|

|

|

|

|

||||

|

rated power

|

11kw

|

|

|

|

|

||||

|

Rated voltage

|

380V±10%/220V±10% Optional

|

|

|

|

|

||||

|

Control System

|

Chinese and English LCD touch screen

|

|

|

|

|

||||

|

Operating environment

|

Operating environment Temperature 0-40°C Humidity 20%-80%RH

|

|

|

|

|

||||

|

software

|

Automatic nesting software, template entry software(Optional)

|

|

|

|

|

||||

Packing & Delivery

AOL CNC automatic asbestos gasket cutting machine

Step 1.

Machine cleaning

Machine cleaning

Step 2.

Wrap all the machine parts with bubble film & plastic film.

Insert necessary anti friction & collision pad at the corner.

Set all the small parts on the machine bed to save space

Wrap all the machine parts with bubble film & plastic film.

Insert necessary anti friction & collision pad at the corner.

Set all the small parts on the machine bed to save space

step 3.

Trailer the full set machine to packing place. Forklift it on the fumigated wooden case. Fix the sticks on the bottom

plywood. Customize wood case according to each model, special groove design, the bottom of the machine and the

top metal structure of the tray is stuck perfectly and prevent the machine from sliding in the wooden case. Reinforce

steel wire outside the wooden case to prevent deformation of the wooden case. Wrap waterproof cloth outside the

wooden box. Prevent wooden case from water and the machine to be rusty

Trailer the full set machine to packing place. Forklift it on the fumigated wooden case. Fix the sticks on the bottom

plywood. Customize wood case according to each model, special groove design, the bottom of the machine and the

top metal structure of the tray is stuck perfectly and prevent the machine from sliding in the wooden case. Reinforce

steel wire outside the wooden case to prevent deformation of the wooden case. Wrap waterproof cloth outside the

wooden box. Prevent wooden case from water and the machine to be rusty

Hot Searches