KINGREAL Fire Control Damper Frame Roll Forming Machine is our self-developed full-automatic production line with high efficiency.

This production line adopts new riveting technology to solve problems due to welding technology. The whole line is standard type, high-efficient and smart, which make it the first choice for producing fire control dampers.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Power:

-

30KW

-

Dimension(L*W*H):

-

200*300*200

-

Sheet Thickness (mm):

-

12MM

-

Production Capacity:

-

15M/Min

-

Name:

-

Roll Forming Bending Machine

-

Type:

-

Full- Automatic

-

Usage:

-

Fire Damper

-

Raw material:

-

Steel Coil

-

Thickness:

-

1.2-2.0mm

-

Roller material:

-

Cr12 Steel Quenched

-

Shaft material:

-

High Grade No.45 Forged

-

Motor brand:

-

Mistubishi

-

Control system:

-

Delta

-

Color:

-

Customer's Requirement

Quick Details

-

Brand Name:

-

KINGREAL

-

Condition:

-

NEW

-

Weight:

-

18500 kg

-

Place of Origin:

-

Guangdong, China

-

Power:

-

30KW

-

Dimension(L*W*H):

-

200*300*200

-

Sheet Thickness (mm):

-

12MM

-

Production Capacity:

-

15M/Min

-

Name:

-

Roll Forming Bending Machine

-

Type:

-

Full- Automatic

-

Usage:

-

Fire Damper

-

Raw material:

-

Steel Coil

-

Thickness:

-

1.2-2.0mm

-

Roller material:

-

Cr12 Steel Quenched

-

Shaft material:

-

High Grade No.45 Forged

-

Motor brand:

-

Mistubishi

-

Control system:

-

Delta

-

Color:

-

Customer's Requirement

What Our Machine Can Do?

Products Description

Fire Control Damper Frame Roll Forming Machine

Production Line Performance:

Raw material: Low Carbon Steel/Gi Steel

Thickness: 1.5-2.0mm

Width of material coil: 278-398mm

Weight of material coil: ≤5000kg

Width of final products: 200-320mm adjustable

Flange type: common plate/angle bar 30/angle bar 40

Power consumption: 25KW

Forming speed: 1~12m/min adjustable

Length tolerance: ±0.3mm

Bending forming tolerance: ±0.3mm

Production type: Decoiling, L-shape, square type, single plate

Control system: PLC control

Raw material: Low Carbon Steel/Gi Steel

Thickness: 1.5-2.0mm

Width of material coil: 278-398mm

Weight of material coil: ≤5000kg

Width of final products: 200-320mm adjustable

Flange type: common plate/angle bar 30/angle bar 40

Power consumption: 25KW

Forming speed: 1~12m/min adjustable

Length tolerance: ±0.3mm

Bending forming tolerance: ±0.3mm

Production type: Decoiling, L-shape, square type, single plate

Control system: PLC control

Technical Support

This Production Line is short type, can save space for factories. It can produce damper frames in various sizes by setting parameters in touch screen operation system and changing perforation molds.

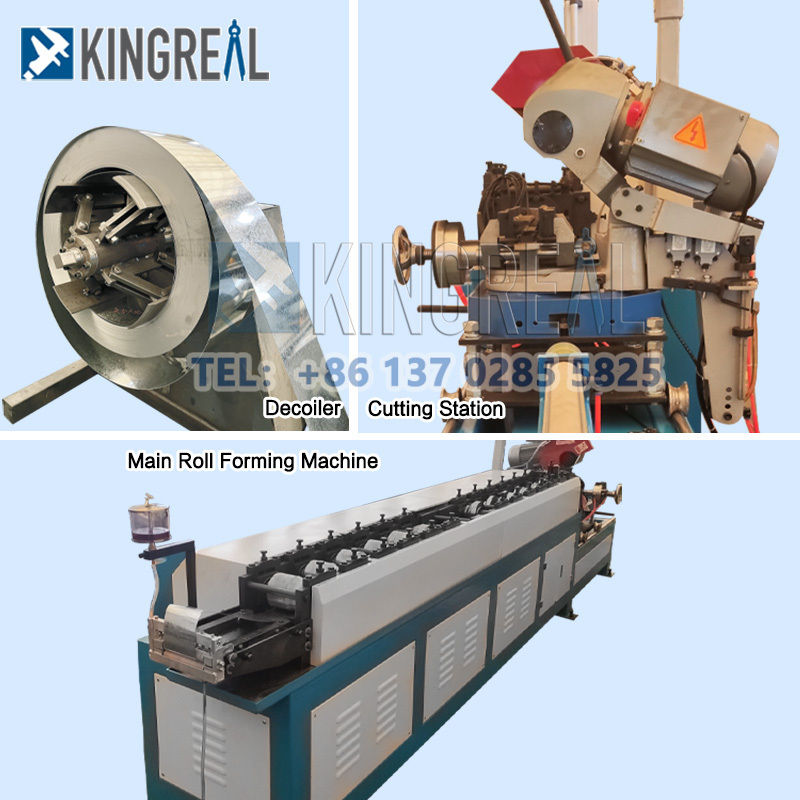

Structure of Fire Damper Frame making machine:

* Decoiler

* Straightener

* Hole Punching System

* Hydraulic Bending Cutting Station

* Electrical Control System

* Decoiler

* Straightener

* Hole Punching System

* Hydraulic Bending Cutting Station

* Electrical Control System

|

Type

|

Full-Automatic

|

|

Produce size

|

200mm, 300mm, 700mm etc.

|

|

Control

|

Touch screen control

|

|

Bending Type

|

Hydraulic Bending

|

|

Punching Station

|

Hole punching

|

|

Roll Forming Stations

|

Around 14 stations

|

Machine Structure

High Precision Straightener

The machine provides high-precision straightening.To ensure straightness of materials,we doubled the amount of precision rolls.

As a result,finished products have higher precision.Leveling rollers,which are made of 40Cr round bars,were thermal refined,quenched at high frequency,electroplated twice and accurately ground.They are smooth,without scratches,their hardness are above HRC62,and regulated by 4 threaded rods.

High quality Hydraulic System

The hydraulic parts use high efficiency energy storage type hydraulic system. And it adopts Taiwan or Germany hydraulic components and equipped with air cooling system. It can be used for the high speed punching and shearing of different roll formed products.

Advantages Of This Machine

Multi stations hydraulic punch system

Our multi-station hydraulic punch system can be designed to fit hole positions of different profiles for performing punching

operations such as multi-station punching and corner cutting.The system is fully automatic and easy to use.It is suitable for

production of shelf columns and furniture profiles.

operations such as multi-station punching and corner cutting.The system is fully automatic and easy to use.It is suitable for

production of shelf columns and furniture profiles.

HIGH QUALITY ELECTRICAL APPLIANCES

We use high-quality imported electrical appliances, such as Japanese Yaskawa NC servo feeder, PLC from FATEK, MCGS touch screens,

which can ensure stable and continuous work of our machines.

which can ensure stable and continuous work of our machines.

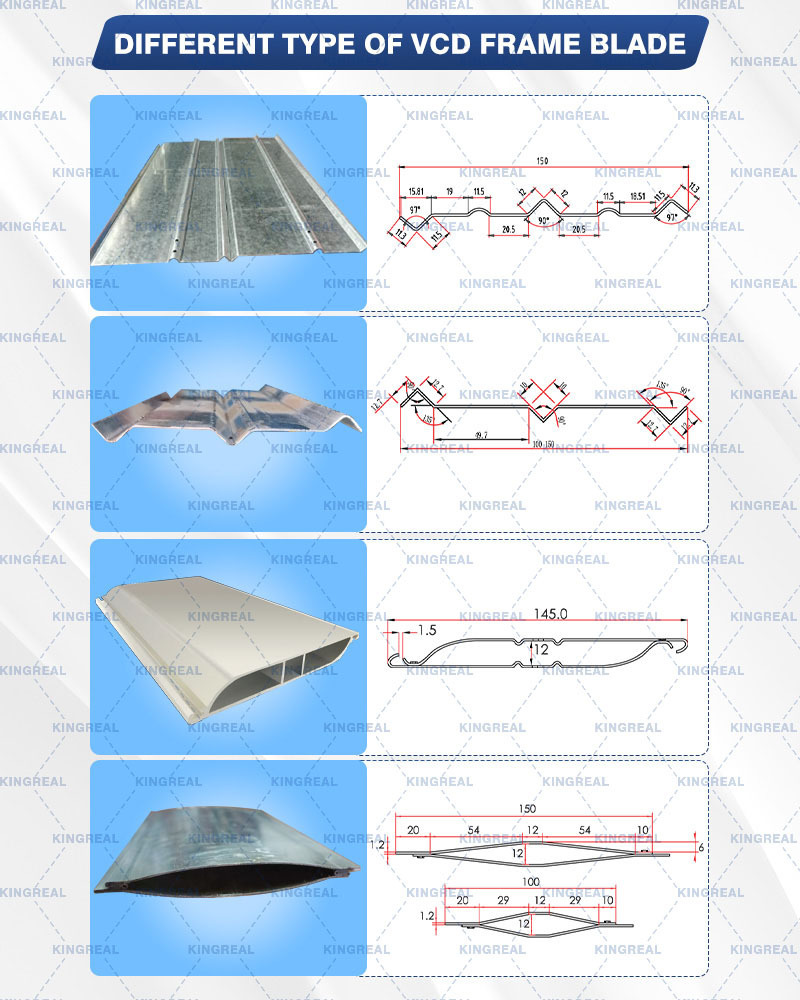

Related products

Fire Frame Blade Roll Forming Machine

Product packaging

Hot Searches