Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Grade:

-

300 Series

-

Surface Finish:

-

2B/BA

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DELONG

-

Model Number:

-

310/310S

-

Application:

-

Heat Exchange,Boile ,Power,Chemical Factory etc, Food And Pharmaceuticals Industry , etc.

-

Outer Diameter:

-

50mm

-

Delivery Time:

-

7-14 days

-

Thickness:

-

0.1mm-60mm

-

Diameter:

-

5-200mm

-

Length:

-

6m-12m

-

Surface:

-

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D

-

Technique:

-

Cold Rolled Hot Rolled

-

Product name:

-

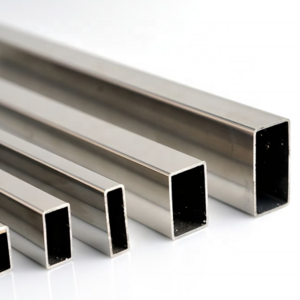

Stainless Steel Round/square Tube

-

MOQ:

-

1 Ton

Quick Details

-

Type:

-

Seamless/welded

-

Steel Grade:

-

301L, S30815, 301, 304N, 310S, S32305, 410, 204C3, 316Ti, 316L, 441, 316, L4, 420J1, 321, 410S, 410L, 436L, 443, LH, L1, S32304, 314, 347, 430, 309S, 304, 439, 204C2, 425M, 409L, 420J2, 436, 445, 304L, 405, 370, S32101, 904L, 444, 301LN, 305, 429, 304J1, 317L

-

Tolerance:

-

±1%

-

Grade:

-

300 Series

-

Surface Finish:

-

2B/BA

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DELONG

-

Model Number:

-

310/310S

-

Application:

-

Heat Exchange,Boile ,Power,Chemical Factory etc, Food And Pharmaceuticals Industry , etc.

-

Outer Diameter:

-

50mm

-

Delivery Time:

-

7-14 days

-

Thickness:

-

0.1mm-60mm

-

Diameter:

-

5-200mm

-

Length:

-

6m-12m

-

Surface:

-

BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D

-

Technique:

-

Cold Rolled Hot Rolled

-

Product name:

-

Stainless Steel Round/square Tube

-

MOQ:

-

1 Ton

Products Description

Stainless steel pipe is one of the hot-selling products of DELONG Steel.

Stainless steel pipe's diameter we produce ranges from 0.25mm to 16mm.

It includes stainless steel capillary pipe, precision stainless steel pipe, and coiled stainless steel pipe.

The pipes are inventoried mainly in 304, 304L, 316, 316L, 310s, 321, 309, etc.

They are wide used in different fields, such as medical device industry, temperature-guided industrial temperature control, sensor used pipe, pens care industry core tube, car antenna tube, mobile phone and computer stylus, etc.

It includes stainless steel capillary pipe, precision stainless steel pipe, and coiled stainless steel pipe.

The pipes are inventoried mainly in 304, 304L, 316, 316L, 310s, 321, 309, etc.

They are wide used in different fields, such as medical device industry, temperature-guided industrial temperature control, sensor used pipe, pens care industry core tube, car antenna tube, mobile phone and computer stylus, etc.

As a leading stainless steel pipe manufacturer, Delong Steel adheres to strict quality standards to produce our stainless steel pipes. We guarantee our products meet our customer’s requirement.

Specifications

|

Specification

|

|

|

|

Size

|

Outer Diameter: 6-2500mm (3/8”-100”);

Wall Thickness: 1-150mm (SCH10-XXS);

Length: As your request

|

|

|

Process

|

Welded

|

|

|

Standard

|

ASTM, DIN, ISO, EN, JIS, GB, etc

|

|

|

Material

|

200 series (201, 201L, 201LN, 202, etc)

300 series (304, 304L, 309S, 310S, 316, 316Ti, 317, 317L, 321, 347, 347H, 316L, etc) 400 series (401, 409, 410, 420J1, 420J2, 430, 439, 440, 440C, 443, 444, etc) Duplex steel (2205, 2507, etc) |

|

|

Surface

|

Polishing, annealing, pickling, bright

|

|

|

Type

|

hot rolled and cold rolled

|

|

|

Price terms

|

FOB, CIF, CFR, CNF, Ex-work

|

|

|

Payment terms

|

T/T, L/C, westen union

|

|

|

Delivery time

|

Prompt delivery or as the order quantity

|

|

|

Package

|

Standard export seaworthy package,or as required.

|

|

|

Application

|

Widely used in petroleum, foodstuff, chemical industry, construction, electric power, nuclear, energy, machinery, biotechnology, paper

making, shipbuilding, boiler fields. |

|

|

Container size

|

20ft GP: 5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM

40ft GP: 12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM 40ft HC: 12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM |

|

|

Stainless Steel Grades

|

|

|

|

|

||||

|

EN-DIN standard steel grade

|

EN-standard steel grade

|

ASTM /AlSIstandard steel grade

|

UNS |

GB-standard steel grade

|

||||

|

1.431

|

X10CrNi18-8

|

301

|

|

|

||||

|

1.4318

|

X2CrNiN18-7

|

301LN

|

|

|

||||

|

1.4307

|

X2CrNi18-9

|

304L

|

S30403

|

|

||||

|

1.4306

|

X2CrNi19-11

|

304L

|

S30403

|

00Cr18Ni9

|

||||

|

1.4311

|

X2CrNiN18-10

|

304LN

|

S30453

|

|

||||

|

1.4301 |

X5CrNi18-10 |

304 |

S30400 |

06Cr19Ni10

( GB/T3280-2007 ) |

||||

|

1.4948

|

X6CrNi18-11

|

304H

|

S30409

|

|

||||

|

1.4303

|

X5CrNi18 12

|

305

|

|

|

||||

|

1.4541

|

X6CrNiTi18-10

|

321

|

S32100

|

0Cr18Ni11Ti

|

||||

|

1.4878

|

X12CrNiTi18-9

|

321H

|

S32109

|

|

||||

|

1.4404

|

X2CrNiMo17-12-2

|

316L

|

S31603

|

00Cr17Ni14Mo2

|

||||

|

1.4432

|

X2CrNiMo17-12-3

|

316L

|

S31603

|

00Cr17Ni14Mo2

|

||||

|

1.4435

|

X2CrNiMo18-14-3

|

316L

|

S31603

|

00Cr17Ni14Mo2

|

||||

|

1.4401

|

X5CrNiM017-12-2

|

316

|

S31603

|

0Cr17Ni12Mo2

|

||||

|

1.4436

|

X3CrNiMo17-13-3

|

316

|

S31603

|

0Cr17Ni12Mo2

|

||||

|

1.4406

|

X2CrNiM0N17-12-2

|

316LN

|

S31653

|

|

||||

|

1. 4571

|

X6CrNiMoTi17-12-2

|

316Ti

|

S31653

|

|

||||

|

1.4429

|

X2CrNiMoN17-13-3

|

316LN

|

S31653

|

|

||||

|

1.4438

|

X2CrNiMo18-15-4

|

317L

|

S31703

|

|

||||

|

|

X10CrNiTi189

|

347

|

|

0Cr18Ni1 1Nb

|

||||

|

1.4512

|

X6CrTi12

|

409

|

|

0Cr11Ti

|

||||

|

|

|

|

S41000

|

0Cr13

|

||||

|

|

|

410

|

|

1Cr13

|

||||

|

|

|

420J1

|

|

2Cr13

|

||||

|

1.4016

|

X6Cr17

|

430

|

|

1Cr17

|

||||

|

1.4118

|

X40CrMo15

|

440A

|

S44002

|

8Cr13

|

||||

|

1.4112

|

|

440B

|

S44004

|

9Cr13

|

||||

|

1.4125

|

|

440C

|

S44003

|

11Cr18

|

||||

|

|

|

440F

|

S44020

|

|

||||

|

1. 4539

|

X1NiCrMoCu25-20-5

|

904L

|

N08904

|

00Cr20Ni25Mo4. 5Cu

|

||||

|

1. 4547

|

X1CrNiMoCuN20-18-7

|

|

S31254

|

|

||||

|

Chemical Composition %

|

|

|

|

|

|

|

|

|

||||||||

|

Grade

|

C

|

Si

|

Mn

|

P

|

S

|

Ni

|

Cr

|

Mo

|

||||||||

|

201

|

≤0 .15

|

≤0 .75

|

5. 5-7. 5

|

≤0.06

|

≤ 0.03

|

3.5 -5.5

|

16 .0 -18.0

|

-

|

||||||||

|

202

|

≤0 .15

|

≤l.0

|

7.5-10.0

|

≤0.06

|

≤ 0.03

|

4.0-6.0

|

17.0-19.0

|

-

|

||||||||

|

301

|

≤0 .15

|

≤l.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

6.0-8.0

|

16.0-18.0

|

-

|

||||||||

|

302

|

≤0 .15

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

8.0-10.0

|

17.0-19.0

|

-

|

||||||||

|

304

|

≤0 .0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

8.0-10.5

|

18.0-20.0

|

-

|

||||||||

|

304L

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

9.0-13.0

|

18.0-20.0

|

-

|

||||||||

|

309S

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

12.0-15.0

|

22.0-24.0

|

-

|

||||||||

|

310S

|

≤0.08

|

≤1.5

|

≤2.0

|

≤0.035

|

≤ 0.03

|

19.0-22.0

|

24.0-26.0

|

|

||||||||

|

316

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

10.0-14.0

|

16.0-18.0

|

2.0-3.0

|

||||||||

|

316L

|

≤0 .03

|

≤1.0

|

≤2.0

|

≤0.045

|

≤ 0.03

|

12.0 - 15.0

|

16 .0 -1 8.0

|

2.0 -3.0

|

||||||||

|

321

|

≤ 0 .08

|

≤1.0

|

≤2.0

|

≤0.035

|

≤ 0.03

|

9.0 - 13 .0

|

17.0 -1 9.0

|

-

|

||||||||

|

630

|

≤ 0 .07

|

≤1.0

|

≤1.0

|

≤0.035

|

≤ 0.03

|

3.0-5.0

|

15.5-17.5

|

-

|

||||||||

|

631

|

≤0.09

|

≤1.0

|

≤1.0

|

≤0.030

|

≤0.035

|

6.50-7.75

|

16.0-18.0

|

-

|

||||||||

|

904L

|

≤ 2 .0

|

≤0.045

|

≤1.0

|

≤0.035

|

-

|

23.0·28.0

|

19.0-23.0

|

4.0-5.0

|

||||||||

|

2205

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.030

|

≤0.02

|

4.5-6.5

|

22.0-23.0

|

3.0-3.5

|

||||||||

|

2507

|

≤0.03

|

≤0.8

|

≤1.2

|

≤0.035

|

≤0.02

|

6.0-8.0

|

24.0-26.0

|

3.0-5.0

|

||||||||

|

2520

|

≤0.08

|

≤1.5

|

≤2.0

|

≤0.045

|

≤ 0.03

|

0.19 -0. 22

|

0. 24 -0 . 26

|

-

|

||||||||

|

410

|

≤0.15

|

≤1.0

|

≤1.0

|

≤0.035

|

≤ 0.03

|

-

|

11.5-13.5

|

-

|

||||||||

|

430

|

≤0.1 2

|

≤0.75

|

≤1.0

|

≤ 0.040

|

≤ 0.03

|

≤0.60

|

16.0 -18.0

|

-

|

||||||||

Available Surface

|

Surface Finish

|

Definition

|

Application

|

|

2B |

Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given

appropriate luster. |

Medical equipment, Food industry, Construction material, Kitchen utensils.

|

|

BA

|

Those processed with bright heat treatment after cold rolling.

|

Kitchen utensils, Electric equipment, Building construction.

|

|

NO.3 |

Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001.

|

Kitchen utensils, Building construction.

|

|

NO.4 |

Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001.

|

Kitchen utensils, Building construction, Medical equipment.

|

|

HL |

Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size.

|

Building Construction. |

|

NO.1 |

The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling.

|

Chemical tank, pipe. |

Product application

It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture,ship components.

It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs,and screen.

It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs,and screen.

Packing & Delivery

About Delong Steel

Shandong Delong Metal Products Co., Ltd is a well-known metal steel supplier with 20 years industry experience. As a leading manufacturer of steel materials, the enterprise has established good cooperative relationships with other famous steel plant like TISCO, Bao Steel, Anshan Steel, JISCO, ZPSS, LISCO and so on,enhancing its capacity to offer best reliable sources of products to clients.

We have 50000 tons regular specifications in stock for fast delivery as well as support custom-made production.

We focus on maximum product performance and customer experience with scientific minimum cost,you will get most cost-effective cost.

All of our products have been certified by Multiple quality certification and we conduct strict high quality control system. Manufacturer Test Certificate and the Third Party Inspection are all available.

We have the world's advanced processing machine to process any size as clients requirements.

Send Your Inquiry Details for Best Quotation & Free Samples,Click “

SEND

” Now!

Hot Searches